All your floor marking questions, answered.

In this complete guide to floor marking, you'll learn how to make the most of your floor tape, paint, or signs. This free 24-page guide will answer your questions about:

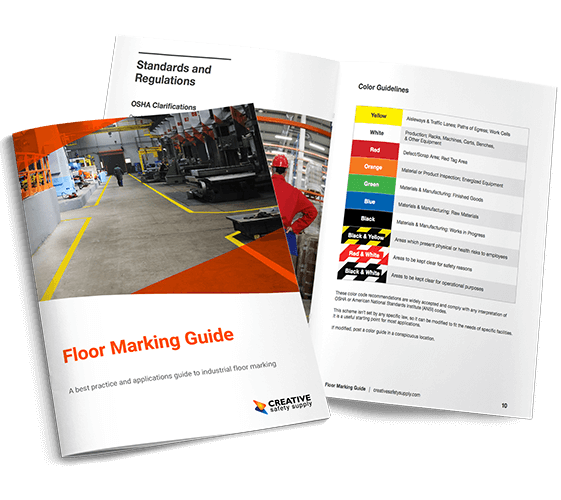

- OSHA requirements for floor marking (hint: there are fewer than you might think)

- Color guidelines & recommendations

- Floor markings that have made other companies successful

- Floor marking tape options (with analysis—including the pros and cons—of each)

Plus, see the top 11 tips for making an effective floor marking system.