OSHA estimates that more than 32 million workers per year in various industries are exposed to chemical and toxic hazards that result in a multitude of injuries ranging from heart damage, nervous system damage, cancer, skin ailments, kidney damage, and what this article will go over today: respiratory damage. Needless to say, people working in such environments need protection from these hazards to preserve their health and well-being, and some of the best ways to begin is by using appropriate respiratory protection and clear communication.

Of course, when employers are looking to improve working conditions and stay compliant with regulation-setting bodies, they must also keep the hierarchy of hazards in mind. As a reminder, within the hierarchy of hazards, PPE is the last resort in protecting employees. The appropriate engineering and administrative controls must be implemented first to eliminate or mitigate the hazards before PPE is even touched, but that doesn’t mean PPE should be thrown to the wayside. Respiratory protection such as the use of respirators has an important role to play in keeping employees safe. Luckily for you, this article will be going over the types of respirators as well as integral regulations that employers must follow to stay OSHA compliant.

Types of Respiratory Protection

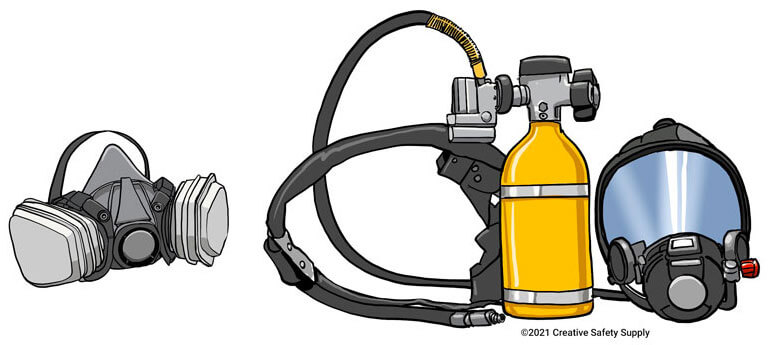

There are two main types of respirators; Air-Purifying Respirators and Supplied-Air Respirators. Choosing correctly between an APR or SAR in a particularly hazardous environment is essential — that often depends on, for example, how saturated the air is with chemicals or the number of particulates suspended in the air. The main difference between the two is that an APR draws air from the surrounding area and filters out contaminants while a SAR pulls clean air from a contained source of oxygen.

Within these two categories, there is also a Powered Air Purifying Respirator (PAPR) that assists the wearer in breathing through filters and something called a Self-Contained Breathing Apparatus (SCBA) that has a finite supply of air in a pressurized container. Both of these respirators function similarly to the above main categories regarding one having a filtering system and one not needing one, but both have slightly different means of supplying air to the wearer.

APRs and PAPRs work by either filtering out particulates hanging in the air or utilizing a sorbent material to filter out gases or vapors via special cartridges. When looking for an air-purifying respirator the user must differentiate between the need to filter out particulates or the need to filter out gases and vapors, otherwise, the respirator will not assist the wearer in breathing without taking in contaminated air.

As a reminder, particulates include:

- Nuisance dusts

- Toxic dust

- Fumes

- Mists

- Radon daughters

- Asbestos in dust or fibers

Gases and vapors include:

- Volatile organic compounds

- Noxious gases like hydrogen cyanide, ammonia, mercury, etc.

SARs and SCBAs supply air from a separate airline or pressurized container respectively. This air never comes from the surrounding work area, which removes the need for filters. Commonly used by firefighters, SCBAs work well in environments that have a higher saturation of hazardous chemicals.

Size, Class, and Efficiency Options

Respirators are available in several different sizes with varying levels of face coverage. The following are tight-fitting respirators:

- Quarter masks cover the nose and the mouth

- Half-face masks cover the nose to below the chin

- Full facepiece masks cover from below the chin to up over the eyes

- Mouthpiece respirators are only used for evacuation purposes. It fits in the wearer’s mouth and includes a clip that keeps the nostrils closed

Loose fitting respirators include:

- Hoods or helmets that cover the entire head

- Face shields with rubber or fabric sides

Three different classes of filters can be chosen from and the user’s choice depends on whether or not oil is involved. Oil degrades the efficiency of the filters which is why it is important to choose the correct class. These are:

- N-Series: These are not oil resistant and can only be used against solid and water-based aerosols.

- R-Series: These are oil-resistant filters; they can work with any particulates but can only be used for one eight-hour shift.

- P-Series: These filters are oil-proof and can be used with any particulate matter. The user must contact the manufacturer or read the label to know how long the filter will last before it must be changed.

Reusable respirators is oftentimes referred to as elastomeric facepiece respirators while disposable ones are simply called filtering facepiece respirators. The difference between the two is that elastomeric facepiece respirators use replaceable cartridges and most likely will be made of a silicone or rubberized material that offers a tight seal to the face. These can be cleaned regularly after use. On the other hand, filtering facepiece respirators do form a tight seal and only cover the nose and mouth to filter out particulates in the air. These are designed to be thrown away after use rather than cleaned and kept.

Each of the above series has three levels of efficiency available. Efficiency in this context is the percentage of contaminants that are successfully trapped within the filter. These are:

- N-Series

- N100 is 99.97% efficient

- N99 is 99% efficient

- N95 is 95% efficient

- R-Series

- R100 is 99.97% efficient

- R99 is 99% efficient

- R95 is 95% efficient

- P-Series

- P100 is 99.97% efficient

- P99 is 99% efficient

- P95 is 95% efficient

Determining what type of respirator to use as well as its size, class of filter, and efficiency rating is of the utmost importance if the wearer wants to be safe from particulates or chemically hazardous air. If not properly chosen, the wearer may suffer lifelong consequences or even death in extreme situations.

Respiratory Protection Standards (1910.134)

OSHA's respiratory protection standard can protect millions of workers in industrial environments and prevent thousands of illnesses and deaths annually from long term damage caused by toxic substances. The respiratory protection standard exists to provide clarity and consistency to information about proven strategies for keeping people safe. These are not optional regulations. OSHA has made these rules mandatory which means a lack of compliance by employers can incite heavy consequences.

With that being said, the following is not meant to be a direct copy of 29 CFR 1910.134, instead it gathers some of the most important information that an employer must start with. Employers must be familiar with this OSHA standard to protect their workers and ensure their safety.

Training Required Under OSHA 29 CFR 1910.134

Respirator training is required to be able to adequately protect oneself in the event of an emergency or recurrent work activity. Training encompasses storage, maintenance, disposal, and of course, use of the respirator. Without training, the wearer may end up breathing in contaminated air or further harming themselves with the respirator itself.

OSHA 29 CFR 1910.134(k) states, “[This standard] requires the employer to provide effective training to employees who are required to use respirators. The training must be comprehensive, understandable, and recur annually, and more often if necessary… the employer [has] to provide the basic information on respirators … to employees who wear respirators when not required by this section or by the employer to do so.”

The topics that must be gone over during the training period include:

- Why the respirator is needed

- Improper usage, fit, and maintenance that will inevitably result in harm

- Respirator limitations and potential malfunctions

- Using the respirator in emergency situations

- Inspecting, donning and doffing the equipment, usage, and checking the seal

- Maintenance and storage

- Recognizing medical signs that may inhibit the respirator’s proper usage

What is a respiratory protection program?

Regulation 1910.134(c)(1) states, “In any workplace where respirators are necessary to protect the health of the employee or whenever respirators are required by the employer, the employer shall establish and implement a written respiratory protection program with worksite-specific procedures. The program shall be updated as necessary to reflect those changes in workplace conditions that affect respirator use.”

A respiratory protection program is comprised of the following:

- A consistent approach for choosing respirators

- A medical evaluation for workers who need respirators to perform jobs

- Compliant fit testing procedures

- Written procedures for employee use of respirators during emergency situations and work specific duties

- Procedures and schedules for maintaining respirators

- Procedures to ensure sufficient performance of respirators

- Training employees on using equipment

- Regularly evaluating the program

- Ensure voluntary use of respirators is compliant and safe for employees

Another thing that would be helpful regarding clear communication is the use of visual cues. Respirator signs are there to help remind employees to be safe in these types of hazardous environments. Without them, you may run the risk of causing an accident due to lack of information.

1910.134 Fit Testing

Fit testing is another important part of correctly using any type of respirator. Without a tight seal, contaminated air may come in contact with the wearer’s lungs. 1910.134(f) describes the normal fit test protocol requirements, one of them being the requirement that the fit test be administered by using an OSHA- accepted qualitative fit test (QLFT) or quantitative fit test (QNFT) protocol.

Qualitative fit testing involves using the wearer’s sense of taste and smell to detect leaks in respirator equipment. This technique does not measure the amount of leakage and is usually done for half-mask respirators. Quantitative fit tests uses a machine to measure the amount of contaminant leaking into the respirator. While it does not rely on the senses of the wearer, it does use a probe attached to the facepiece that is hooked to a sensor on the machine. This type of test can be used for any category of tight-fitting respirator. Both tests must be done with negative pressure rather than positive pressure to ensure a true tight fit.

When performing a fit test, the employee must also wear the things they would be wearing in a real situation involving the respirator. These can be glasses or earmuffs as some examples. Unfortunately, those who have beards may have to shave to ensure a good seal.

While this is not an exhaustive list of the requirements of fit testing, these are some of the most important parts. OSHA’s complete standard on respiratory protection is important to be familiar with.

Overall, respiratory protection should not be taken lightly. There are regulations for a reason—employers have an obligation to protect employees from long lasting injury. Do your part and put up respiratory protection signs and become familiar with OSHA’s regulations to keep your workers safe from harm.

Similar Articles

- OSHA Ear Protection Requirements (Standards for Hearing Safety)

- PPE: Personal Protective Equipment [Safety Standards]

- Fall Protection in the Workplace: OSHA’s Guidelines

- ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]

- OSHA’s Guidelines to Protecting Employees from Coronavirus

- Understanding the OSHA 300 Log and Other Incident Paperwork

- NFPA 25: Standards for Fire Protection Systems

- What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

- Understanding OSHA/ANSI First Aid Kit Requirements