Ships house a network of pipes to keep them functioning while at sea. These powerful engines rely on interconnected, industrial pipes to transport wastewater, fuel, freshwater, exhaust from critical areas of the vessel, and much more.

Without pipe markings to convey these substances, crew members may get confused and damage equipment or machines during operations or maintenance services. The ISO 14726

specifies a set of rules for marking pipes to communicate content and hazards in piping systems.

Marine Pipe Marking Standards

The REG ISO 14726: Ships and marine technology, Identification colours for the content of piping systems provides a standardized color coding system, based on the content and function on board ships and marine vessels. The standard is reviewed every five years to introduce improvements in recognition of additional hazards or safety precautions.

The current ISO 14726 standards specify the following requirements:

Color Coding

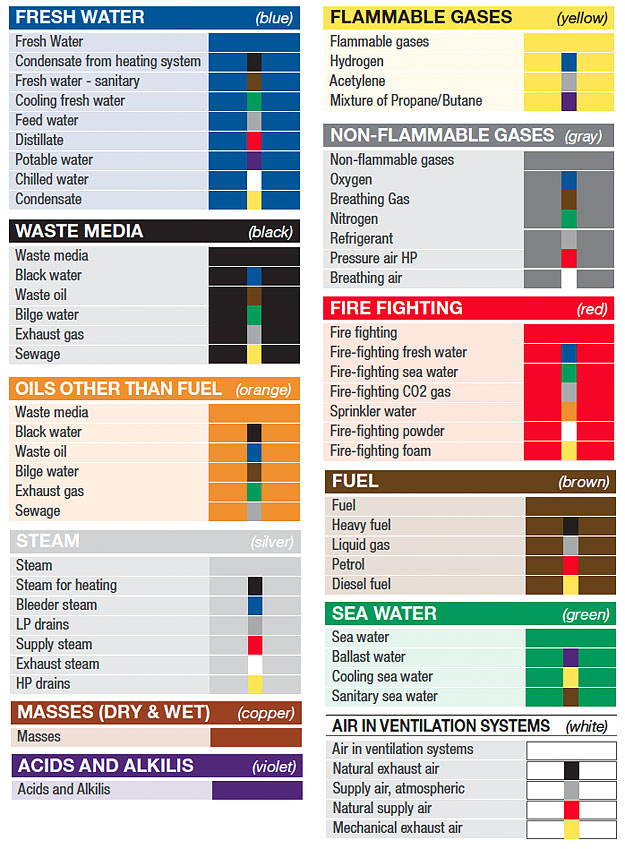

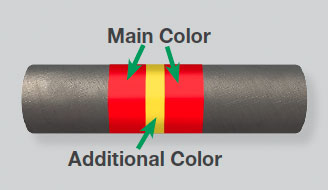

Similar to the (ANSI/ASME A13.1) pipe marking color code, the ISO 14726 uses a color coding system of “main colors” and “additional colors” to convey the contents of a pipe within the maritime vessel. These main colors are used to identify the class of the content (e.g., blue for freshwater), while the additional colors (such as a green solitary band in between to indicate potable water) specify the type of substance flowing through the pipe.

The main colors used in ISO 14726 are as follows:

Legend

While color coding is the primary means of identification, the ISO 14726 standard suggests using a legend (the name of the contents) to provide unambiguous information about the pipe's content and/or function, especially for those unfamiliar with the color codes.

Label Size

The size of the label generally differs based on the diameter of the pipe. The primary dimensions for pipes per color band are 50mm per color band. Considering that there are three color bands present on the pipe label, it should be around 150 mm (15cm) in length. This number can vary based on the dimensions of the pipe.

We recommend following the chart attached below for maximum visibility for first-responders and personnel:

| Outside Diameter of Pipe or Covering | Length of Color Field | Letter Height |

|---|---|---|

| 0.7 in–1.3 in (18–33 mm) | 8 in (203 mm) | 0.5 in (13 mm) |

| 1.4 in–2.4 in (34–61 mm) | 8 in (203 mm) | 0.7 in (19 mm) |

| 2.5 in–6.7 in (62–170 mm) | 12 in (305 mm) | 1.3 in (32 mm) |

| 6.8 in–10 in (171–254 mm) | 24 in (610 mm) | 2.5 in (64 mm) |

| Over 10 in (Over 254 mm) | 32 in (813 mm) | 3.5 in (89 mm) |

Placement

Since marine environments often include tight corridors, varying elevations, and complex pipe arrangements, consistent marker placement is as important as correct color coding or sizing. ISO 14726 outlines specific placement requirements to ensure maximum visibility, reduce confusion, and support safe operations. The key placement guidelines require:

- Apply labels at regular intervals on straight run pipes to ensure clarity of the pipe's contents at every angle.

- Remember to place a label every time a pipe changes direction. For example, if a pipe enters a twist or corner, a label should be present at that point of change.

- A label should be present at any point a pipe passes through the hull or deck of the ship or through any physical structure.

- Place a label close to each valve, pump, and other important equipment.

- Pipe markers should be visible from a normal range of approach. In the case that pipes are attached too high, the label should be angled down, facing the audience to alert and attract attention.

Flow Direction

Unlike other standards, Marine Pipe Marking Standards do not require marking pipes for flow direction. Although this is not required, experts strongly advise marking the direction of flow with arrows or arrow-band tape, which is most commonly observed in pipe marking standards in industrial facilities. Additionally, using text helps avoid confusion about the contents of your pipes for someone not yet familiar with the ISO/DIS standards. This can help enable workers and maintenance personnel to avoid the path of pressure when performing routine services.

Equip Ships With Industrial-Grade Pipe Labels

Maritime ships rely on pipe labels to help ensure safety and compliance with international standards that focus on personnel safety against potential hazards. At Creative Safety Supply, we provide durable marine signs and access to a free marine and offshore pipe marking guide to boost safety and create a safe environment.

Similar Articles

- Water Treatment Pipe Marking

- Medical Substance Pipe Marking | NFPA99/CGA C-9

- Ammonia Pipe Marking Standards | IIAR Requirements

- A Guide to Pipe Marking Standards

- ANSI Color Codes for Pipe Marking

- Understanding Canadian Pipe Marking Standards (CAN/CGSB-24.3-12) and Hazard Symbols

- Your Guide to Pipe Labeling Standards

- Abandoned Pipe Marking Requirements Under ANSI/AMSE A13.1

- Pipe Color Codes – ANSI/ASME A13.1

- Floor Marking for Facility Safety