Create durable TPM Labels using LabelTac® printers.

Print your own durable, indoor/outdoor TPM labels and tags in-house.

The LabelTac® family of industrial label printers makes creating labels easy, quick and hassle-free. With the included LabelSuite™ labeling software , visual communication has never been easier.

The software allows you to choose your label supply type, colors, and size. Then add text, choose any symbols you'd like to add, and print! It's that easy!

Learn More › Watch Video ›Get Started with LabelTac® Labeling Bundles

Featured Bundle

LabelTac® Pro X 5S Bundle

Everything you'll need to start printing labels for your 5S program right away: a LabelTac® Pro X industrial label printer, label creation software, label supply in a variety of colors and sizes, print ribbon, and helpful training tools.

Shop now ›Other Safety Labeling Bundles:

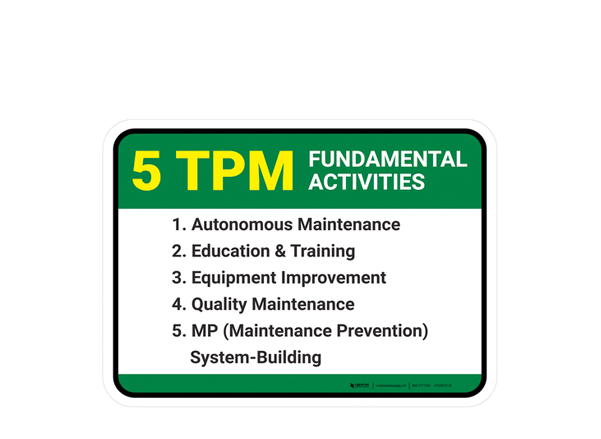

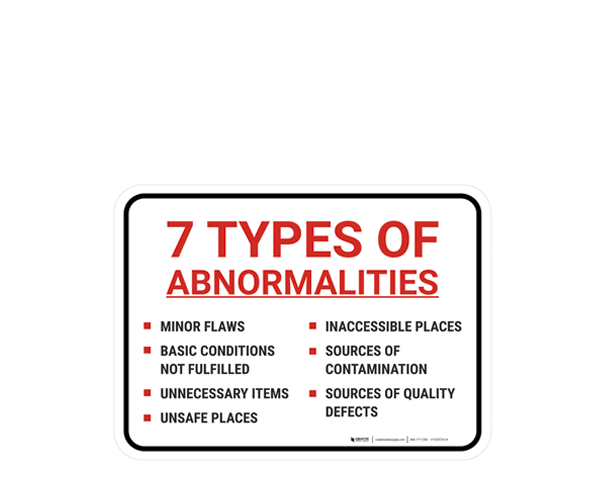

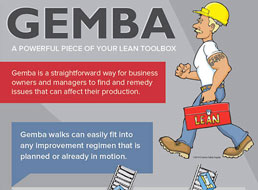

TOTAL PRODUCTIVE MAINTENANCE (TPM) GUIDE

Prevent inefficiencies and enhance safety through the power of TPM system.

The FREE guide includes:

- Understand all 8 pillars of TPM, the OEE framework, and the Six Big Losses

- A step-by-step walkthrough makes it easy to set up your own TPM plan

- Learn the subtle differences between TPM and TQM

- Straightforward information and real-world examples take the mystery out of TPM

TPM Products

Free Guides & E-Books

View all ›For more TPM information, please visit the TPM Resource Center.

Free 5S Label Samples

5S project coming up? Test the high quality and versatility of LabelTac® labels ahead of time.

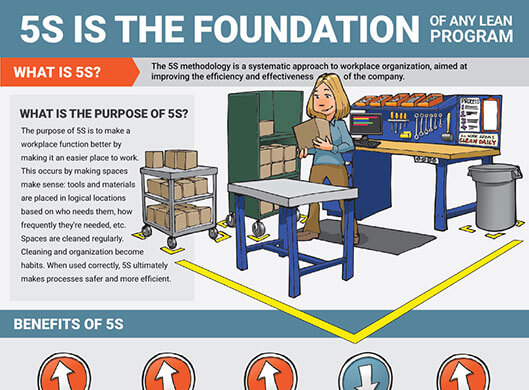

Choosing to implement 5S in the workplace is a step in the right direction if you are trying to improve employee safety and cut down on those familiar eight wastes of Lean. We'd be happy to send you a box of sample 5S labels to get you up and running for your new continuous improvement program! Test the versatility and high-quality product that is LabelTac® and see how these labels enhance communication and organization.

Get Free Samples ›-

Every facility has unique needs when it comes to labeling. Whether it be for OSHA compliance, safety, health, informational, or organizational reasons. We know pre-made labels don’t cut it for some special projects. That’s where our team here... More details

-

Label a receptacle as trash only so that recyclable items are not thrown away. Helps reinforce environmental awareness. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant... More details

Trash Only Label

$3.75 -

Reminds personnel to recycle whenever possible. Helps increase environmental awareness. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without leaving messy... More details

Recycle Label

$3.75 -

Mark hazardous waste bins and disposal locations to prevent accidental contact and reduce health risks. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without... More details

-

An effective reminder for your workers to follow the 5S principles, which helps in the "sustain" portion of the program. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant... More details

Remember 5S Label

$3.75 -

Pitch In Put Trash In Its Place with Icon Landscape - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh... More details

-

Label a receptacle as a general recycling container that can take all types of recycleables. Helps prevent trash contamination. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear... More details

-

Mark areas specifically for storage. Helps prevent misplacement or storage in the incorrect area. Great for 5S labeling to sustain organization for efficient work.MINIMUM QUANTITY OF 2 LABELS PER ORDER More details

Storage Area Label

$3.75 -

Please Keep Lids Closed with Icon Portrait - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh... More details

-

Label a receptacle for metal scrap. Helps ensure proper recycling of metal. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without leaving messy residue Same... More details

Metal Scrap Only Label

$3.75 -

Place Garbage Inside Dumpster Landscape - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh environments... More details

-

Creative Safety Supply's Revealed Series Presents: Lean Revealed - Lean Manufacturing in Today's Workplace Have you been charged with learning what Lean Manufacturing is but don't know where to start? Some organizations believe Lean Manufacturing... More details

-

Label hazardous waste storage locations so proper care is used during operation or transportation. 3 size options available Easy peel-and-stick application Strong adhesive for high durability Chemical, water, and smear resistant Removable without... More details

-

Notify personnel and others that only glass recycling is to be contained inside the receptacle. Helps prevent cross contamination of trash and different recycleables. 3 size options available Easy peel-and-stick application Strong adhesive for high... More details

Glass Only Label

$3.75 -

Place Trash In Proper Container with Icon Landscape - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh... More details

-

Place All Refuse In Can with Icon Landscape - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh... More details

-

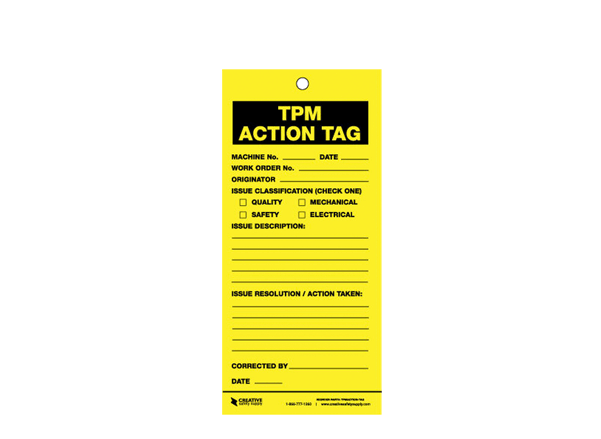

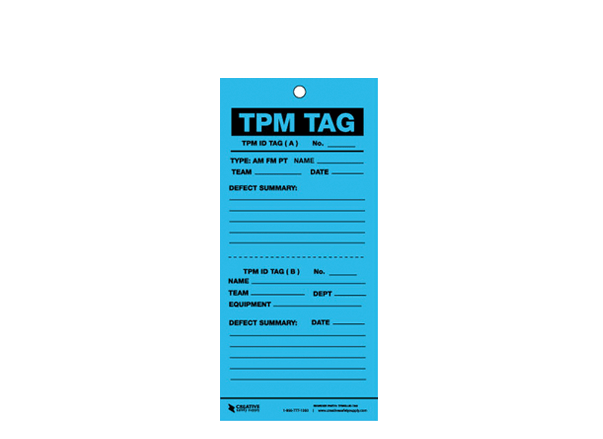

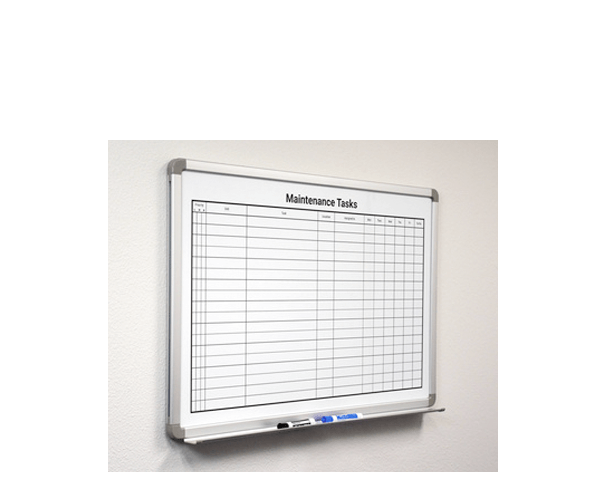

TPM Tags - Tag Station The TPM Tags - Tag Station allows for quick and easy labeling while providing storage and tidy tag organization. This board features a vibrant magnetic tag holder that can be placed not just on the whiteboard itself, but... More details

TPM Tags - Tag Station

$59.99 -

TPM Action Tags - Tag Station The TPM Action Tags - Tag Station allows for quick and easy labeling while providing storage and tidy tag organization. This board features a vibrant magnetic tag holder that can be placed not just on the whiteboard... More details

-

Please Dont Litter Help Keep Your Community Clean with Icon Portrait - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed... More details

-

Please Deposit All Rubbish In Receptacles Landscape - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh... More details

-

Pitch In with Icon Portrait - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh environments and provide... More details

-

No Littering with Icon Portrait - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh environments and... More details

-

No Littering Please Use Trash Can with Icon Portrait - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh... More details

-

No Hazardous Materials In Dumpster Landscape - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh... More details

-

Dumpster Rules Guidelines Portrait - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh environments and... More details

-

Deposit Recyclables Here Arrow Down - Label Able to be placed on products, packaging, equipment, and other locations where larger signage might not be a good fit. Made from our durable high quality vinyl that is designed to survive harsh environments and... More details