Pipelines are used to transport a wide range of different liquids, gases, and vapors throughout facilities in a safe and efficient manner. Pipelines, while they are a safe option for transport, can carry hazardous chemicals that have the potential to cause serious harm to employees. For that reason, it is necessary to ensure that pipes are properly labeled.

If a pipe is not labeled, employees working on the piping may not know what the pipe contains, and therefore, may not take the necessary precautions. This is especially important since pipes carry such a wide range of different solutions, making it impossible to predict what is inside without tracing the pipe back, which would be inefficient.

For example, if an employee opens up a pipe that is expected to be water, but it is actually some type of toxic gas or fluid, it is easy to see how this could cause a very serious problem. Fortunately, pipeline labeling is a fairly easy process and can virtually eliminate the risk of someone working with a pipe without knowing what is within.

When learning about the best ways to label piping in a facility, it is a good idea to look into this free pipe-marking guide that contains the necessary standards put forth by ANSI.

ANSI Pipe Labeling Standards

There are many pipeline labeling standards that need to be followed. Some of these standards are put in place by regulatory agencies like OSHA, and others are recommended by ANSI or other institutions. Regardless, there are many standards that lay out what the labels must say, as well as where they must be placed that companies can choose to follow based on their specific working conditions.

The ANSI/ASME A13.1 standard is the most commonly followed standard for marking pipes today. In fact, most all companies that utilize piping in their facilities should know about this necessary standard.

Not sure which pipe labels you need?

The pipe label calculator helps you choose the right labels for your pipes.

While ANSI is not a governmental agency and has no legal power to force any company to follow their standards, almost all companies do try to comply with them. In addition, when OSHA and other governmental agencies choose to make requirements regarding pipe markings, they will almost always turn to ANSI standards as the basis of the law.

ANSI is a very respected institution throughout virtually every industry, which is why businesses tend to listen to their recommendations. Their standards are made in such a way as to help improve safety, without putting any type of undue burden on the businesses or the employees. This is an excellent balance that has helped to drive improved pipe safety for years.

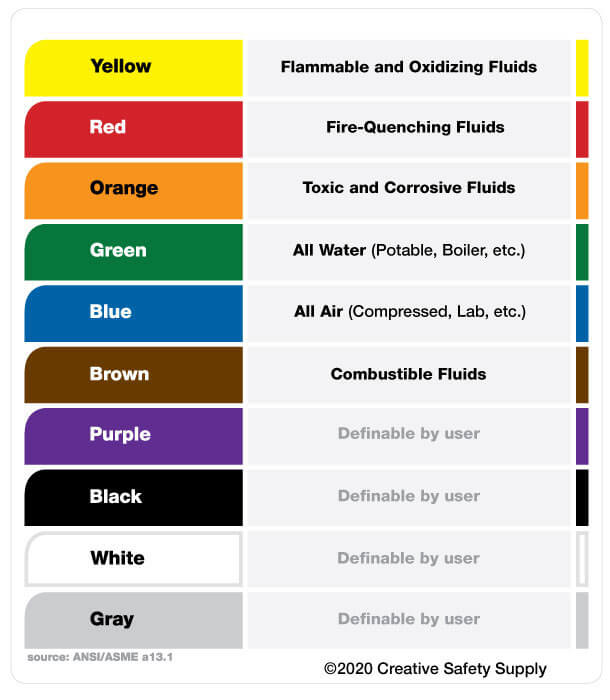

ANSI/ASME A13.1 Pipe Color Code

Labels used on pipes will typically need to follow the color codes established by ASME in their A13.1 standard, which has been most recently updated in 2020. The following are the most common pipe color code standards that will be used in most facilities:

- Black text on Orange background – This is to be used for toxic and corrosive fluids.

- Black text on Yellow background – This is to be used for flammable and oxidizing fluids.

- White text on Brown background – This is for combustible fluids.

- White text on Green background – This is for water that is for cooling, boiler feed, potable, and other water.

- White text on Blue background – this is for pipes containing compressed air.

There are also a variety of different color combinations that are reserved for 'user-defined' pipe contents. This is important since it will allow facilities to use pipe markings with colors that they can be confident won't mean something else in the coming years.

The current user-defined colors for pipe markings are white text on purple background, white text on grey background, white text on black background, and black text on white background. It can be helpful to carry a quick pocket guide to identify what each of the colors mean. Many facilities will also put up larger signs that contain the color meanings to help remind employees in the area.

The Optional Use of GHS Symbols

There is even the option to include GHS pictograms on a pipe marking label if the pipe leads to a holding container that has a standard GHS label. This is to provide continuity and a maximum level of communication between workers and their environment. If this route is chosen, the label must follow the A13.1 standard color scheme, as well as include the following information:

- The product identifier

- The pictogram(s)

- The signal word

- The physical, health, and environment hazard statement

How to Label Pipelines

Labeling pipes can be an easy process, as long as the person or team doing the labeling has the right equipment and is following all the rules and regulations governing this process. Investing in everything that is needed is well worth the effort for any company that has piping that needs to be labeled.

Pipe Marking Equipment

Most facilities that do their own pipeline markings will want to have an industrial label printer to create and print off the labels that are needed. These printers come with software that can be used to design the exact type of label that is needed so that it complies with ANSI and other requirements. One of the best things about having a label printer like this on site is that the labels can be customized as needed, and they can be printed off whenever a new one is required.

Pipe markings are often quite different from other types of labels, so it is important to plan everything out and get it right the first time. These markings should include an arrow to indicate which direction the pipe contents are flowing, and additional information about what is in the pipe. Reviewing the requirements for pipeline markings is going to be essential for safety and compliance.

The Different Types of Pipe Markers

There are a variety of different types of labels that can be used. The specific one that is correct for a given situation will depend on things like how much information needs to be conveyed, what is in the pipes, the environment that the pipe is in, etc. The following are some common types of pipe markers that facility owners or safety managers should be aware of so they can use them if appropriate:

- Arrow Tape - Arrow tape is simply a strong tape that has arrows on it. When installed, it will clearly show which direction the pipe flows. This is often used along with pipe marking labels or signs.

- Shrink Wrap Labels - Wrapping a pipe with a label and then having it shrunk down to tightly fit over the pipe is an effective option. This is typically done with a heat gun and will allow information to be shown on all sides of the pipe itself.

- Pipe Markings - Pipe marking labels, which are the standard pipe labels that contain information about what is in the pipe, are likely the most common way that a pipe is labeled today. They offer important information both for those working with the pipes and emergency workers who need to be aware of what is in them.

- Patterned Tape - Patterned tape can draw additional attention to a pipe when necessary. This could be a black and yellow stripe that is meant to remind people to take caution when working on the piping. Like the arrow tape, this option is typically going to be used along with standard pipe marking labels.

Using any of these tapes, it becomes easy to outfit the pipes in any facility. Labels can be made to the exact size that is needed based on the diameter of the pipe that needs to be marked. However, this can only be done if the right equipment is available, or if the facility orders custom made pipe marking tape to be used in that facility.

Keeping Pipe Markings Visible

ANSI and ASME clearly state that pipe labels are to be placed above or below the horizontal centerline of the pipe in instances where pipelines are located above or below the normal line of vision to maximize visibility for employees. Legends should also be placed near valves and flanges as well as changes in direction, branches, instances where pipes pass through walls and floors, and at sufficient intervals along straight runs. Abandoned piping should also be labeled appropriately according to the updated A13.1 standard.

Once pipe markings are applied to the pipes, it is important to ensure they remain visible to everyone who may be in the area. This would include people who are working directly on the pipes, and those who may be working around them at any time.

To ensure a pipe remains visible, it is necessary to ensure there is lighting available to show the markings. It is also important to keep the labels clean. Pipe markings are made with a high-quality material so that they can be cleaned using just about any normal cleaning solutions. Maintenance teams can wipe them down if they become dirty with dust or grease.

Should a label become damaged; it needs to be replaced right away to ensure the information displayed on the label is always easy to see. Even if most people working in the area have become familiar with what is on the labeling, emergency responders would not know, which is why it is so critical to ensure that pipeline markings are easily visible and readable at all times.