Although the practice of marking pipes has existed for centuries, standardized marking systems, such as ANSI/ASME A13.1, emerged in the 20th century as a response to industrial expansion and growing safety concerns. Today, following these standards is often legally required, with OSHA enforcing them through incorporation by reference or its General Duty Clause. This reinforces the importance of compliant pipe labeling for safety and legal accountability.

This comprehensive blog covers key aspects of pipe marking, including the types of markers, essential label elements, and specialized requirements for ammonia, medical gases, fire systems, and more. It also provides steps for implementing a labeling system and maintaining its effectiveness. Whether establishing or updating a system, this pipe labeling and marking guide will assist you.

Pipe Marking Regulations and Standards

In the U.S., pipe marking is governed by a combination of legal requirements from the OSHA and the widely adopted industry consensus standard ASME A13.1. While OSHA does not have a specific pipe marking standard that applies to all industries, it enforces proper pipe marking through two primary methods:

General Duty Clause:

Section 5(a)(1) of the OSH Act requires employers to provide a workplace free from "recognized hazards" that could cause serious harm or death. For pipes containing hazardous substances, a lack of clear labeling is considered a "recognized hazard." To address this, OSHA considers voluntary compliance with consensus standards like ASME A13.1 to be the industry best practice and may issue citations to companies that do not follow them.

Incorporation by reference:

OSHA's 29 CFR 1910.261 explicitly references the ASME A13.1 scheme for pipe identification. This makes compliance with ASME A13.1 mandatory for facilities in this industry.

ANSI/ASME A13.1 Pipe Marking Standard

The ANSI/ASME A13.1 standard is the most common guideline for pipe marking in the United States, recently updated in 2023. It establishes a system for identifying the contents and hazards of piping systems, detailing the necessary elements for effective labeling, such as color, letter type, and size, and label placement, all aimed at improving safety. A significant update in the 2015 revision included the recommendation to use GHS (Globally Harmonized System) pictograms for labeling hazardous materials, improving hazard communication across different languages and regulations.

While the ANSI/ASME standard dictates pipe labeling in the USA, international standards vary in color codes and placement rules, while all aim to improve safety. Some examples include:

For facilities that operate internationally, it is important to be aware of and comply with the pipe-marking standards applicable in each region.

Pipe Marking Elements

Effective pipe marking requires several components, standardized in guidelines like ASME A13.1, to promote workplace safety by facilitating the identification of pipes and their contents. Necessary elements include:

The Legend (Label Text):

Brief and informative text that names the pipe's contents. It can also include information on temperature or pressure if they pose a hazard.

Color Coding:

A color scheme helps employees quickly identify the general class of substance within the pipe. The ANSI/ASME A13.1 standard provides a common framework with predefined color combinations, while also allowing facilities to develop their own user-defined schemes to meet specific needs. Here are some of the color combinations specified by the ANSI A13.1 standard for pipe marking:

Direction of Flow:

Arrows are essential to show which direction the contents are moving, helping users understand the system's layout.

Label Size:

Labels and text must be appropriately sized to be legible from a safe distance, with size often dependent on the pipe's diameter.

Label Placement and Frequency:

Labels must be placed where they are easily visible and should be repeated at regular intervals to ensure constant visibility.

Location:

Labels should be placed at all points where identification is necessary, such as at changes in direction, where pipes branch, or where they pass through walls or floors.

Specialized Pipe Marking Standards for Unique Hazards & Conditions

While most industries follow the general ASME/ANSI pipe marking standards, certain sectors require more specific regulations for safety and compliance. These specific standards ensure that hazards are communicated clearly in unique environments.

Some examples include:

Different Types of Pipe Markers

Pipe markers come in various types, made from different materials that offer diverse levels of durability and environmental resistance. They also feature different application methods. Here are some common examples:

Implementation Steps of Pipe Marking

Proper implementation of pipe markings is essential for ensuring safety, compliance, and easy identification throughout a facility. Effective implementation involves the following steps:

and Maintenance

Common Pipe Marking Mistakes To Avoid

These are some frequent pipe marking errors that can lead to safety risks or compliance violations:

- Using incorrect colors or text sizes.

- Omitting flow direction arrows.

- Failing to label inaccessible or hidden pipes.

- Choosing non-durable materials in extreme environments.

- Ignoring maintenance and reinspection needs.

Adopting a structured implementation plan and best practices can help prevent these pipe marking mistakes.

Consequences of Unlabeled or Incorrectly Marked Pipes

Not marking or mislabeling pipes can lead to severe consequences, including:

Health and Safety Risks:

Unmarked or improperly marked pipes increase the risk of serious accidents for workers and others in a facility. A person might mistake a hazardous chemical line for a water line during maintenance, or the wrong medical gas could be administered to a patient. Improperly marked non-potable water pipes can lead to poisoning from accidental ingestion.

Operational Errors & Equipment Damage:

Mislabeled or unmarked pipes can lead to costly mistakes, including connecting incompatible substances or running the wrong fluid through a piece of equipment. This can cause corrosion, blockages, or mechanical failure.

Environmental Contamination:

If a mislabeled pipe leaks, its contents could contaminate the surrounding soil, groundwater, or surface water.

Legal and Financial Repercussions:

Businesses can incur legal action, substantial fines, and increased insurance premiums for failing to comply with safety standards set by regulators like OSHA.

Pipe Marking Tools, Materials, and Maintenance

Pipe markings are essential, but they can fade or become illegible over time due to environmental factors and wear. Regular maintenance and the right tools are essential for keeping these markings visible and compliant. Here are key tools and practices for initial application and ongoing upkeep:

Pre-Made Pipe Markings

Pre-made labels are a quick and convenient solution for standard pipe contents like “HOT WATER” or “COMPRESSED AIR.” These labels are typically made with durable, fade-resistant materials to withstand industrial conditions and maintain clarity over time.

Custom-Made Pipe Markings

When you need to label unique pipe contents, custom markers are necessary. Manufacturers can create markers with specific text, color coding, and sizing to meet your exact needs.

Label Printers

For facilities with extensive or frequently changing pipe marking needs, an industrial label printer is a cost-effective solution.

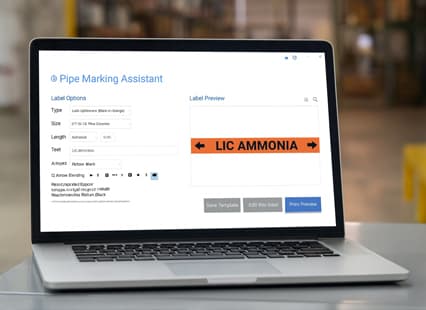

Pipe Label Software

Various software tools are available that simplify the creation of compliant and standardized pipe markers.

Pipe Marking Protections

To extend the life of your pipe labels, consider using industrial label protection. Choosing materials with built-in UV resistance also helps protect against sun exposure and fading.

Pipe Marking Cleaners

Routine cleaning of pipe markings helps maintain legibility. Use cleaning agents that are safe for label materials to avoid premature wear. A regular maintenance schedule ensures markings stay readable and compliant.

Ready to Jump onto Pipe Marking Action?

Keeping your pipe markings clear, durable, and up to date is more than just good practice; it’s essential for safety, regulatory compliance, and operational clarity. Whether you are labeling new systems or refreshing worn-out pipe markings, the right tools and regular maintenance make all the difference.

Get started today with durable, high-quality pipe marking supplies and a printer from Creative Safety Supply. Ensure your facility stays safe, compliant, and well-marked with solutions built for tough environments.

FAQ’s

Still confused about something?

Jump to the bunch of Questions and Answers for Pipe marking!

Pipe Marking Questions and AnswersHelpful Resources