Ammonia refrigeration systems are widely used in industrial and commercial facilities due to anhydrous ammonia’s excellent cooling efficiency and relatively low environmental impact. However, despite these benefits, anhydrous ammonia is hazardous and poses several risks, making clear identification of ammonia piping critical for worker safety and regulatory compliance.

To address these risks, the International Institute of Ammonia Refrigeration (IIAR) established specific requirements for ammonia pipe marking based on ANSI/ASME A13.1 guidelines. While these requirements were historically published as IIAR Bulletin No. 114, they are now fully incorporated into Informative Appendix Q of ANSI/IIAR Standard 2-2021.

In this guide, we will discuss the IIAR ammonia pipe marking standards, covering the required information that must appear on ammonia pipe markers, the formatting requirements for labels, and the importance of proper identification in industrial environments. We will also look at the history and evolution of these standards that shaped the labeling requirements used today.

Key Ammonia Pipe Labeling Requirements Outlined in IIAR Standard 2-2021/ Bulletin 114

The current ammonia pipe labeling requirements were originally established in IIAR Bulletin 114 and are now fully incorporated into Informative Appendix Q of ANSI/IIAR Standard 2-2021. These guidelines provide a consistent, standardized approach for identifying ammonia refrigeration piping and system components through clearly defined labels.

Each ammonia pipe marker is required to convey critical information, including the pipe’s contents, physical state, pressure, flow direction, and system function. To ensure this, every ammonia pipe marker consists of five essential components:

- Marker body

- Physical state section

- Pressure level section

- Abbreviation section

- Directional arrow

Ammonia Pipe Marker Body

The marker body – also known as the pipe label – background should be orange. This is because ANSI A13.1 associates the color “orange” with “warning,” indicating that the pipe’s contents are either corrosive or toxic. This provides a visual cue for employees and personnel to better understand and immediately recognize the pipe’s contents. The lettering of the pipe should be in black.

Physical State

This section reflects the state of the ammonia, and whether it's in liquid, gas, or a combination of both. According to the IIAR Bulletin 114, the requirements for each section are as follows:

- Liquid: The abbreviation, “LIQ,” should be printed on a yellow band in a circumferential arc band adjacent to and to the left of “AMMONIA.”

- Vapor: For pressurized vapor, “VAP” in black lettering should be present on a sky blue band in a circumferential arc adjacent and left of “AMMONIA.”

- Liquid & Vapor: Based on the above-mentioned colors, both abbreviations “LIQ” and “VAP” should be present adjacent to and left of “AMMONIA.”

Pressure Level

Labeling the pressure of ammonia within pipes is highly crucial, the IIAR states:

- For pressure greater than 70 PSIG: Print “HIGH” in black letters on a red band in a circumferential arc adjacent to and right of “AMMONIA.”

- For pressure less than or equal to 70 PSIG: Print “LOW” in black letters on a green band in a circumferential arc adjacent to and right of “AMMONIA.”

There are also color codes on how to mention the pressure of ammonia in a piping system:

- High Pressure Liquid: Orange (Pantone 152C)

- High Pressure Vapor: Yellow (Pantone 109C)

- Low Pressure / High Temperature Liquid and Vapor: Light Blue (Pantone 298 C)

- Low Pressure / Low Temperature Liquid and Vapor: Dark Blue (Pantone 3015 C)

- Low Pressure / Low-Low Temperature Liquid and Vapor: Purple (Pantone 2617 C)

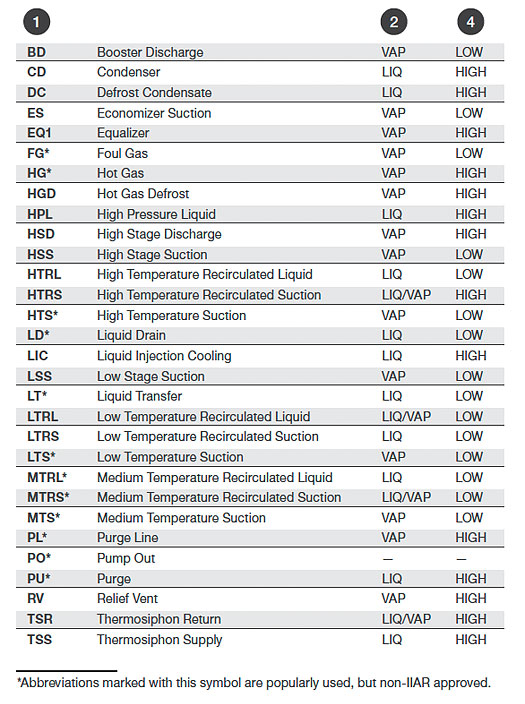

Abbreviation

Certain acronyms must be used to identify the different parts that make up the ammonia refrigeration system, such as HTRLS, LTRS, etc. These abbreviations should be printed in black lettering on the orange label, adjacent to and left of the physical state section.

Beyond this, there are additional abbreviations that can be found in our Free Ammonia Pipe Marking Guide.

Directional Arrow

Arrows should be present on the pipe marker to depict the flow and direction of the contents in the pipes. Directional arrows should be:

- Black in color

- Equal in size to the label

- Can also be applied to the entire length of the ammonia pipe marker

Required Diameter

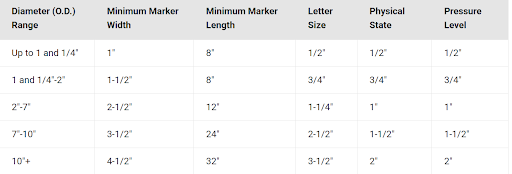

The contents of the ammonia pipe marker should be at a certain height, where they are clearly visible to the naked eye. To ensure this, the contents of the ammonia pipe marker should follow the size specifications provided in the chart below:

Importance of IIAR Compliant Ammonia Pipe Marking

Labeling pipes with ammonia pipe markers is essential in order to alert workers, ensure damage control, and maintain compliance with international organizations. Ammonia labeling goes beyond compliance with safety regulations; it is the heartbeat of safety culture in industrial facilities. They help exercise control during emergencies, aiding through clear identification to help support emergency first responders and manage valve shut-offs to mitigate risks.

Ammonia pipe markers also help:

- Help new employees exercise safety

- Prevent major fine litigations

- Clear confusion and provide clear identification to maintenance workers

Recent Updates in IIAR Ammonia Pipe Marking Standard

In 2019, IIAR Bulletin 114 underwent important updates. The list of standard abbreviations was expanded from 17 to 31 to accommodate the growing complexity of ammonia refrigeration systems. The color scheme for physical states was also revised, with the LIQUID state changing from orange to yellow for better clarity.

Most notably, in 2021, all of the guidelines from Bulletin 114 were incorporated into Informative Appendix Q of ANSI/IIAR Standard 2-2021, titled “Standard for Safe Design of Closed-Circuit Ammonia Refrigeration Systems.” This consolidation means that pipe labeling now exists as part of a broader system safety standard, making it easier for facilities to implement both design and labeling guidelines together.

The integration of Bulletin 114 into ANSI/IIAR 2-2021 streamlines ammonia refrigeration safety protocols and ensures that pipe labeling is directly tied to overall system design and safety standards. This makes it easier for facilities to stay compliant with both safety regulations and industry best practices.

Improve Your Workplace Safety With Compliant Ammonia Pipe Markers

Labeling ammonia pipes according to the IIAR standards can help you improve your facility’s safety culture and ensure compliance, and with Creative Safety Supply, you can achieve that. We offer a range of ammonia labeling supplies, including bundles of IIAR-compliant ammonia pipe markers and industrial-grade printers for you to design labels on the go.

Similar Articles

- A Guide to Pipe Marking Standards

- Medical Substance Pipe Marking | NFPA99/CGA C-9

- Marine Pipe Marking | ISO/DIS 14726

- Water Treatment Pipe Marking

- Your Guide to Pipe Labeling Standards

- Ammonia Refrigeration

- ANSI Color Codes for Pipe Marking

- Anhydrous Ammonia – Safety & Labeling

- Pipe Color Codes – ANSI/ASME A13.1

- Industrial Floor Marking Guidelines