We've got good news and bad news about industrial floor marking regulations. The good news is that official regulations are almost entirely non-existent, meaning there's technically no wrong way to apply floor markings. The bad news is that while official regulations are almost entirely non-existent, floor markings are crucial to the productivity of a facility and the safety of its inhabitants. That means it falls to you to design a simple system, without the aid of official guidelines to assist your planning efforts.

Not sure which floor tape you need?

The floor tape finder helps you choose the right floor tape for your job.

OSHA's Limited Recommendations

While OSHA has not devised comprehensive rules for industrial floor markings, it does have two requirements, regardless of what sort of facility you're working with.

According to OSHA standard 1910.144, the color red must be used to indicate the following items:

- Stop signs

- Barricades and temporary obstructions

- Danger signs

- Buttons or electrical switches used for emergency stopping of equipment

- Containers of flammable liquid (excluding properly labeled and secured shipping containers)

OSHA also recommends that the color yellow be used to suggest "Caution." It's especially useful for marking striking hazards, tripping hazards, and falling hazards.

Though far from comprehensive, these two regulations make a lot of sense. Not only do they suggest labeling anything potentially hazardous with appropriately vivid color, but they're colors we've all grown accustomed to viewing as indicators of danger anyway. Thus, these two regulations are straightforward, intuitive, and make sense in any industry.

Helpful Tips And Color Combinations

Though any decisions beyond the two OSHA requirements above are yours to make, below you'll find a list of common colors that have proven effective in a variety of facilities:

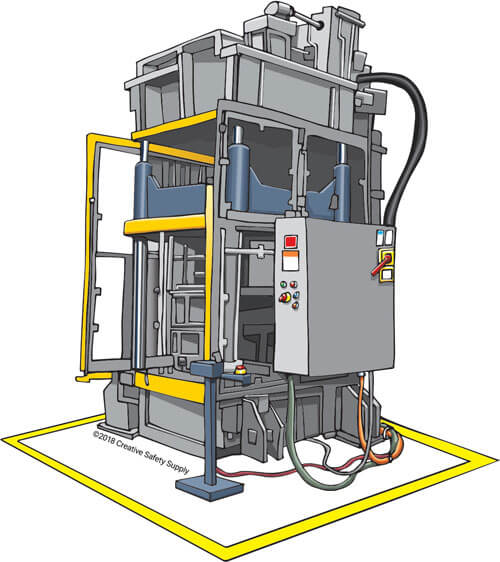

- White Floor Tape

White tape should be used for anything related to facility equipment, fixtures, racks, carts, and things of this nature. Outlining them with white tape alerts people to their presence and also lets people know where to put them when they're done using them. - Blue/Green/Black Floor Tape

These three colors are often used interchangeably because they can easily be confused with one another, especially in darker areas. They are often used near raw materials as well as around any finished goods or products that are in progress. - Orange Floor Tape

Any products, materials, or supplies that are currently being held for inspection. - Red & White Floor Tape

Any area that must be kept clear for safety or compliance should be marked with red and white tape. This will typically be placed around fire extinguishers, emergency eye wash stations, or fire lanes. - Black & White Floor Tape

Areas that need to be kept clear for general operations should be marked with black and white tape. This is not to be used for emergency or compliance areas. - Black & Yellow Floor Tape

If there is a physical health hazard in an area, black and yellow tape should be used to mark the area.

Likewise, we've compiled a few helpful tips to keep in mind while plotting your floor markings:

Don't Go Overboard On The Color Scheme - Using as few colors as possible will make it easier for your employees and guests to remember what each one means.

Be Consistent - Follow the same standards throughout the facility. If your company has more than one facility, make sure the floor marking color standards are uniform across all locations.

Training is Crucial - Take the time to train all employees, contractors, and anyone else who will be spending time in the facility regularly. People must know what each color means, especially during a high-stress time such as an emergency.

Post The Color Code - Having signed up in strategic locations throughout the facility that list the colors and what they mean will serve as a constant reminder and refresher of the training people receive. In some cases, these types of workplace postings are required. This will also help any guests who are in the facility if they need to quickly know what something means.

It's Not Just About The Tape - Remember, the color codes should apply to more than just the lines on the floor. If you are using floor marking shapes or signs, the color standards should be consistent throughout it all.

Resources

Similar Articles

- Floor marking comprehensive research, education and training

- Floor Marking for Facility Safety

- OSHA Floor Marking

- Safety Colors (OSHA Guidelines and Color Codes)

- Floor Marking for Factories

- Floor Marking for Electrical Panel Compliance

- Floor Marking for Fire Extinguishers

- Types of Floor Marking

- Floor Marking Ideas for Warehouses