Have you heard about the Bhopal disaster? It was a tragic industrial accident where a leak of methyl isocyanate (MIC) gas from a pesticide plant in Bhopal, India, resulted in thousands of immediate deaths and long-term health issues for hundreds of thousands more. This incident, along with other industrial accidents in the late 20th century, highlighted the critical need for stricter regulations and robust management systems for hazardous processes, particularly in industries handling highly hazardous chemicals. Developments were made to improve safety procedures, including the establishment of OSHA's Process Safety Management (PSM) standard to prevent catastrophic events.

In this artilce, we will discuss Process Safety Management (PSM), specifically focusing on when it's used, its core elements, and the role of visual communication within it. Let’s get started!

What is Process Safety Management?

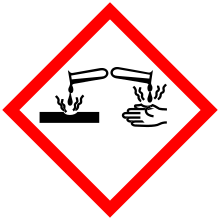

Process Safety Management (PSM), as defined by OSHA, is a systematic approach to managing the risks associated with hazardous chemicals in industrial processes. It focuses on preventing major incidents like fires, explosions, and toxic releases by ensuring processes are designed, operated, and maintained safely. PSM encompasses a range of elements working together to identify, evaluate, and control hazards.

When is a Process Safety Management Program Required?

OSHA requires that process safety management be used when highly hazardous chemicals are necessary for production or are a byproduct of a process. There are 130 chemicals classified as highly hazardous. Once the possession threshold limits are exceeded or if the site is storing 10,000 pounds or more of a Category 1 flammable gas or liquid with a flashpoint below 100 °F, then a process safety management system is necessary to prevent accidents.

On the other hand, storing flammable liquids with flashpoints below 100 °F in atmospheric tanks or transferring them do not need PSM programs as long as they can be kept below their boiling points without the help of refrigeration.

The need to implement process safety management doesn’t involve retail facilities, oil, and gas well drilling, servicing operations for oil and gas, or normally unoccupied facilities. While still potentially dangerous, hydrocarbon fuels for workplace consumption like heating or gasoline refueling do not fall under the jurisdiction of this standard.

Benefits of Compliance With OSHA’s Process Safety Management Requirements

Complying with OSHA's 29 CFR 1910.119 standard helps with reducing overall risk in potentially hazardous environments. When a facility properly implements the process safety management standards, as required by OSHA, they are working to prevent disasters involving these dangerous chemicals. The risk preventatives simultaneously assist in helping educate employees and others nearby to identify and take the necessary steps to avoid injury as well as property damage.

What are the 14 Elements of PSM?

Once an organization has determined that it must implement a PSM program to keep its workers safe, it will find that there are 14 elements specified within OSHA's process safety management standard to establish an effective PSM program. While this is not an exhaustive list of information on the standard required by OSHA, it does include the basics of those 14 elements:

- Employee Participation: All employees involved with facility operations should be informed of the PSM program and all its elements. Employees must also be represented in meetings where PSM is addressed. Each of the following aspects of PSM should have an experienced team to work with as well.

- Process Safety Information: All highly hazardous chemical information needs to be compiled by the employer into a written document for reference. This must be done before any process hazard analysis is completed. The document must include information on the chemicals, technology used, and equipment used in the process.

- Process Hazard Analysis: This type of analysis must be conducted once every five years with the help of several analysis methods and will attempt to rank the greatest risks while resolving the high-priority ones first. The analysis itself must be completed by a team of engineering and maintenance experts as well as at least one knowledgeable employee who specializes in that process. They will then work to identify, evaluate, and eventually control the hazard present.

- Operating Procedures: For each operating phase the facility will need to address the initial process setup and startup instructions, normal and temporary operating conditions, and normal and emergency shutdown situations. All operators need to be aware of these conditions to be able to identify when deviation from normal conditions occurs and how to prevent them from happening.

- Training: Operator training will be provided by the employer and will emphasize the process’s specific safety and health hazards, safe work practices, and what to do in emergencies. Refresher training will be provided every three years at the very least. Once training has been completed, documentation must be kept on the date as well as a means of verifying that the employee understood the safety training.

- Contractors: Those who are hired to come in to perform maintenance, repair, renovation, turnaround, or specialty work must be evaluated by the employer regarding the contract employer’s safety performance and programs. The employer must warn the contractors of the potential danger of the highly hazardous chemicals and provide them with the basics of an emergency action plan as a precaution. They must also come up with safe work practices for the contractors to abide by. This information will be relayed to all other contractors before work has begun.

- Pre-startup Safety Review: The employer is required to perform a pre-startup safety review for new and modified facilities when the change is large enough to alter the process safety information.

- Mechanical Integrity: Pressure values, storage tanks, piping systems, relief and vent systems and their devices, emergency shutdown systems, controls, and pumps must be inspected routinely and documented. The procedures for checking this equipment must be contained in a written document and follow recognized and generally accepted good engineering practices.

- Hot Work: The employer must issue a hot work permit for when the activity will be conducted on or near a covered process. The permit must be kept on file until the task is completed.

- Management of Change: There must be a standard procedure for managing changes in chemical processing, technology, equipment, and other necessary procedures. The employer must take into account the technical basis for the change, the impact it has on the safety and health of employees, the modifications required for operation, the necessary period for the changes, and the authorizations needed for the changes to take place.

- Incident Investigation: An investigation must take place within 48 hours of an incident or a near miss involving the release of highly hazardous chemicals. The report must contain the date of the incident, a description, the contributing factors, and resulting recommendations. These reports must be kept for at least five years following the event.

- Emergency Planning and Response: Employers must establish an emergency action plan in accordance with 29 CFR 1910.38 and may be subjected to also follow the hazardous waste emergency response provisions within 29 CFR 910.120.

- Compliance Audits: Every three years the employer must verify that all practices and procedures under 1910.119 are being followed. The employer must keep the two most recent audits on file.

- Trade Secrets: Employers must make necessary information known as required in the previous sections despite the possession of a trade secret, as employee safety takes priority.

These PSM elements are interconnected and work together to create a comprehensive safety system. For example, Process Safety Information (PSI) is essential for conducting Process Hazard Analysis (PHA), and the findings of the PHA can be used to develop effective Operating Procedures and Emergency Plans. Similarly, Employee Participation is vital for the success of all other elements, ensuring that everyone is engaged in maintaining a safe work environment.

Similar Articles

- Improving Workplace Electrical Safety

- Quality, Health, Safety, Environment (QHSE) Management Systems

- Workplace Safety Inspections & Audits

- Safety Colors (OSHA Guidelines and Color Codes)

- ISO 31000:2018 – Risk Management

- Anhydrous Ammonia – Safety & Labeling

- Material Safety Data Sheets [How-To Guide for Upgrading to SDS]

- Job Safety Analysis

- Warehouse Management (Supply Chain Systems + Visual Management)

- A Guide to Workplace Safety Signs