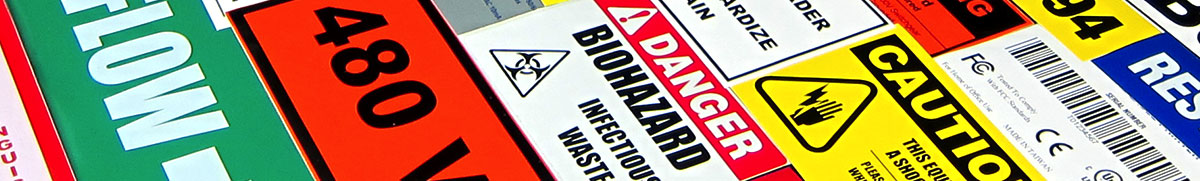

Safety colors act as visual cues, communicating hazards and providing safety instruction at a glance. The Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI) developed a standardized system in which each color designates a specific hazard. This visual approach enables employees to remain vigilant about potential risks, ensuring a safe and constructive workplace.

When employees find these color codes on machinery, signs, or specific locations, they can act upon them to prevent accidents. If you are unaware of these safety color codes, this article will help you get up to speed.

OSHA Safety Color Codes

OSHA has released a set of safety color codes, each with a significant meaning that communicates the level of danger or risk in a particular area.

Red

- Danger, about workplace-related hazards that can incur significant injury.

- They are universally used to signal the need to stop.

- Used to indicate fire-related hazards, such as flammable liquids or open flames.

- Indicates the presence of fire protection equipment

Yellow

- Remind workers to wear PPE

- Point out wet floors

- Warn workers of in-use heavy machinery

- Alert workers of piping systems carrying hazardous waste

Orange

- Exposed or moving machine parts

- Low clearance levels of machinery, meaning the equipment isn't fully deemed safe

- Electrical hazards

- Work Zone markings

- Road construction signs

Green

- First-aid kits and other medical equipment

- Emergency eye-wash fountains in chemical labs

- Suggest safe practices to ensure safety measures are applied

Blue

- To avoid smoking or point where to smoke

- Communicate procedures, information, and instructions

- Remind employees to wear protective equipment, like eyeglasses or a face shield

Black & White

- Housekeeping directives.

- Used to indicate protocols within large-scale facilities.

- It can be used in commercial parking lots to point drivers in the right direction.

Purple

- Pharmaceutical companies

- Chemical facilities

- Industrial piping systems that carry toxic fluids

These color-coded signs and markings allow people to immediately determine the type of safety hazard in the area, even if they are too far away to read any actual writing.

OSHA’s Recommended Code For LOTO Tags

Workers are continuously at risk from hazardous energy released from machinery. To address these hazards, OSHA has recommended a proper lockout/tagout (LOTO) system to indicate the status of machinery and equipment. Here’s a breakdown of the safety color code for LOTO tags:

Red Tags: Indicate that the machinery should not be operated/used.

Yellow Tags: Indicates out-of-service equipment

Orange Tags: Provide hazardous warnings relevant to the machine to ensure safe use.

Orange & Red Tags: These are used to warn workers of the exposure of a biological hazard.

Basic Color-Coding Requirements from OSHA

Danger:

Danger signs are only used when there is an immediate risk to the life and health of an employee. OSHA requires these signs to be red or predominantly red. Any lettering or symbols must be a contrasting color to ensure maximum visibility and bring attention to the hazard.

Warning:

The warning category is for when there is a risk, but it is not as severe or immediate as when danger is used. The safety color associated with warning is orange or predominantly orange. As with the red, any lettering or symbols must be a contrasting color.

Caution:

This category is for alerting people to a potential risk. Caution signs must use the color yellow.

Biological Hazards:

Biohazard dangers have gotten their own category because of the unique risks they present. When issuing a safety alert about biohazards, the color to use is fluorescent orange or an orange-red color.

Similar Articles

- ANSI Color Codes for Pipe Marking

- Pipe Color Codes – ANSI/ASME A13.1

- Industrial Floor Marking Guidelines

- Electrical Wiring (Wire Color Codes)

- OSHA Floor Marking

- Pipeline Labeling

- OSHA Safety Sign Requirements [1910.145]

- Electrical Wire Colors

- Floor Marking for Facility Safety

- OSHA Floor Marking Requirements You Should Know