- What Is ANSI Z535?

- ANSI Z535.1 | Safety Colors

- ANSI Z535.2 | Environmental and Facility Safety Signs

- ANSI Z535.3 | Criteria for Safety Symbols

- ANSI Z535.4 | Product Safety Signs and Labels

- ANSI Z535.5 | Safety Tags and Barricade Tapes (for Temporary Hazards)

- ANSI Z535.6 | Product Safety Information in Product Manuals, Instructions, and Other Collateral Materials

- Updated Z535 Standards

One of the most essential sets of standards is the ANSI Z535 series. This is a series of standards relating to the design, application, and use of signs and labels for presenting safety and accident prevention information. The standards go over many essential design including the formatting, the colors used, the use of safety symbols, and more. Having a good understanding of these standards critical for keeping your facility safe and your workers alert.

The American National Standards Institute (ANSI) is responsible for creating some of the most widely adopted standards in the country. ANSI doesn't have strong enforcement options since it is not a governmental institution, but despite that, most companies follow ANSI standards because they are so highly respected and known for helping ensure safety.

What Is ANSI Z535?

The ANSI Z535 standards are broken down into six parts numbered Z535.1 through Z535.6. This makes it easier for facilities to reference the exact portion of the standards they need at any given time and helps ensure the standards are easier to understand for those in the facility. It is aligned with the international ISO 3864 standard and is officially administered and published by the National Electrical Manufacturers Association.

ANSI Z535.1 | Safety Colors

ANSI Z535.1 sets the standards for the colors used on safety signs. It provides readers with detailed definitions for the signs, the color standards that should be used, the tolerances for the colors, and more. OSHA has adopted the safety sign color codes set forth by ANSI and whenever creating or buying safety signs, it is a good idea to double check to make sure the colors are in line with the colors listed in this section. For example, the color red is not just used for fire signs! It is also the designated color for danger signs, for labeling containers of flammable liquids, emergency stop buttons, and more.

ANSI Z535.2 | Environmental and Facility Safety Signs

When making safety signs that are used for facilities and out in the environment, all signs must follow a uniform look and style. The ANSI Z535.2 standard establishes a format for safety signs that helps people recognize the size, shape, symbols, lettering, and other components of a safety sign, even from a distance.

Safety Alert Symbol

Just about everyone is familiar with the safety alert symbol; it is a triangle with an exclamation point in the middle. The safety alert symbol is used to communicate potential personal injury hazards. People can recognize this item no matter what industry they work in, which is why it is such an important part of safety signs.

Signal Words & Safety Headers

Another important component of the Z535.2 standard is the use of signal words. The signal words are the large, bold words that draw people's attention to the top of the sign and communicate the level of hazard present. The ANSI-approved signal words are as follows:

- DANGER - Danger (written in white, surrounded by red) is used for situations where there is a specific hazard present that will cause a serious injury or even death if people don't actively avoid it. The danger signal word should only be used in the most serious situations.

- WARNING - The word warning (written in black, surrounded by orange) is the right choice when there is a serious hazard that could result in injury or death.

- CAUTION - Caution (written in black, surrounded by yellow) is used for hazardous situations that, if not avoided, might cause an injury that is classified as minor to moderate. When used without a safety alert symbol, "Caution" signs can be used as an alternative to "Notice" signs.

- NOTICE - Notice (written in white, surrounded by blue) is used for signs that convey other information when there is no hazard present and no risk for personal injury. Can be used for instructions, to indicate safety procedures, or to alert workers of the location of safety equipment.

Safety Words

Finally, the safety sign typically includes a written message that gives more details to the person viewing the sign. While there is no set length that the word message must be, it is generally a good idea to keep it as brief and concise as possible. Wording like "BRIGHT LIGHT! Wear Eye Protection" could be used on a sign.

ANSI Z535.3 | Criteria for Safety Symbols

Safety symbols are one of the most important aspects of any good safety sign. Symbols are used in many industries and typically have the same or similar meanings. They are usually bold, black symbols with a white background. ANSI recognizes four types of safety symbols: hazard alerting symbols, mandatory action symbols, prohibition symbols, and informational symbols. Providing employees with training on the specific symbols used in the facility will help them quickly learn their meaning. This is critical for safety because it makes it easier to convey a specific safety message to as many people as possible. Even those who can't read or don't know the language can quickly understand the meaning of these safety symbols.

ANSI Z535.4 | Product Safety Signs and Labels

This section of the Z535 standard establishes requirements for the design, application, use and placement of safety signs and labels on products. Compliant safety labels must clearly communicate hazards an individual may encounter when using, operating, or servicing a wide variety of products. It is important these messages are printed on a durable sign or label to ensure a high degree of resistance from chemicals, rough environments, and extreme heat. The colors of the safety label or sign, the symbols used, the wording, and the signal word used must be compliant with the rest of the standards in the ANSI Z535 series.

ANSI Z535.5 | Safety Tags and Barricade Tapes (for Temporary Hazards)

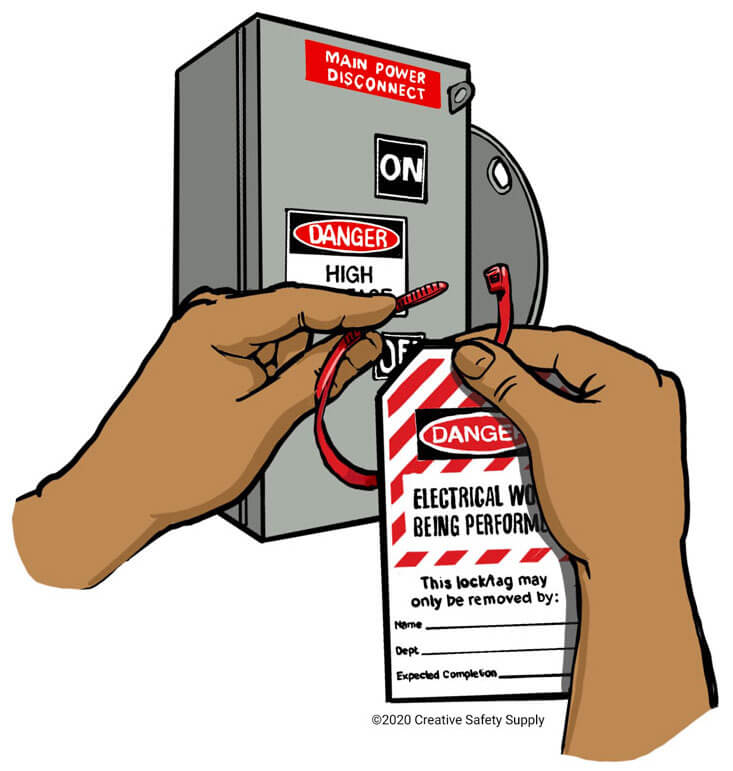

Putting up safety signs, temporary barriers, or other types of visual safety items to alert people to a temporary hazard is covered in this section. Temporary hazard operations and hazardous areas should be marked off properly with tags or tape until the hazard is eliminated or the operation has been completed. Examples of what falls under the Z535.5 standards include safety tags used in lockout / tagout procedures, temporary floor marking tape to mark off an area with a spill, or a removable barricade blocking access to a machine being serviced.

ANSI Z535.6 | Product Safety Information in Product Manuals, Instructions, and Other Collateral Materials

Creating product safety manuals, giving employees safety instructions about when and where to use signs, and other extra material should follow the ANSI standards (for signal words, the safety alert symbol, and safety colors) covered in this last section of the Z535 standards. The goal is to integrate and harmonize safety signs and labels with the information presented in collateral material such as owner's manuals, user guides, service manuals, assembly instructions, and more.

Updated Z535 Standards

Most facilities have been using safety signs, labels, and other items for years and likely have great results thanks to the standards set by ANSI. For those businesses that have been open for more than a few years, it is quite possible that they are using the older ANSI Z35.1-1968 and/or ANSI Z535.1-1967 standards.One of the biggest differences between the old and new safety sign standards is the amount of text on a sign and the clarity. Having slightly more text allows safety signs to convey information much more clearly, which makes them far more useful to the average employee.

Most facilities have been using safety signs, labels, and other items for years and likely have great results thanks to the standards set by ANSI. For those businesses that have been open for more than a few years, it is quite possible that they are using the older ANSI Z35.1-1968 and/or ANSI Z535.1-1967 standards.One of the biggest differences between the old and new safety sign standards is the amount of text on a sign and the clarity. Having slightly more text allows safety signs to convey information much more clearly, which makes them far more useful to the average employee.

These are the older standards that were used by OSHA for quite some time, but are now being phased out. While it is not strictly required that a facility update all its safety signs to the new standards, it is a good idea. Even if a facility does not do one large overhaul, it can slowly transition into the updated standards as older signs wear out or need to be replaced.

2017 ANSI Updates

In an effort for continuous improvement, the ANSI Z535 series is revised. every five years. The most recent round of revisions was published in 2017; ANSI updated the standard for safety colors (Z535.1) and reaffirmed the other five standards in the series.

ANSI Z535.1-2017 establishes a uniform color system for safety signs and labels. The standard was primarily changed to make it more accessible and easier to understand for the user; it was also updated to align with the ISO safety colors. The amended safety color chart includes six Pantone colors, defining a “window of tolerance” for acceptable shades. One of the most notable changes to the chart was removal of the colors safety brown and safety gray.

When to Use ANSI Z535 Safety Signs & Labels

Facilities that need to follow OSHA and other regulatory guidelines often have trouble determining when and where these signs are needed. This can be even more confusing when dealing with groups like ANSI, which technically doesn't have enforcement powers like OSHA does.

Facilities that need to follow OSHA and other regulatory guidelines often have trouble determining when and where these signs are needed. This can be even more confusing when dealing with groups like ANSI, which technically doesn't have enforcement powers like OSHA does.

For safety signs and labels, there are a number of mandatory regulations and many best practices that are recommended by not required. For facilities, the best way to handle this type of situation is to start by taking steps to ensure all the mandatory items are covered and then begin implementing other best practices as time and budget allow.

This is a good idea not only because will it help improve the overall safety of the facility, but it is also a great way to prepare for the future. OSHA often takes good practices and turns them into mandatory regulations down the road. When facilities implement these best practices now, they are ahead of the curve for when OSHA does make some type of requirement.

A good example of this is the ANSI Z535 standards. While OSHA certainly accepts them as fulfilling regulatory requirements, they don't yet mandate that companies transition to this standard. Most safety experts agree, however, that this is something that will happen in the coming years.

Resources

Similar Articles

- OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]

- ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]

- ANSI Color Codes for Pipe Marking

- Pipe Color Codes – ANSI/ASME A13.1

- OSHA Safety Sign Requirements [1910.145]

- What are ANSI standards?

- ANSI TIA 606-B Cable Labeling Standards

- Understanding OSHA/ANSI First Aid Kit Requirements

- Safety Colors (OSHA Guidelines and Color Codes)