- ANSI/ASME Pipe Marking Standards

- Pipe Color Code from ANSI/ASME A13.1

- Incorporate GHS Pictograms and Pipe Markings

- Determining the Size of Pipe Labels

- Unique Pipe Marking Color Standards

- Training Employees on Pipe Marking

- Why is Pipe Labeling Important?

- Types of Pipe Labels

- Choosing the Right Pipe Marking Supplies

- Creating Pipe Labels with an In-House Printer

When looking to implement or update a pipe marking system, it’s important to start with gathering as much information as possible. This means poring over NFPA color codes, ANSI codes, utility color coding charts, etc. While the concept of pipe marking looks to be straight forward, there is actually a lot to learn in order to successfully become compliant with pipe marking standards. It is common knowledge that visual communication plays a crucial part in employee safety, which is why a variety of pipe marking standards exist in the industrial world. In fact, marking visible pipes helps foster a heightened sense of awareness in employees when they are around potentially hazardous chemicals.

With that in mind, this guide has been put together to help provide a one stop source for everything about pipe marking and how to go about it. It will include different standards that exist, how to choose the right pipe marking material, using valve tags, and much more.

ANSI/ASME Pipe Marking Standards

The American Society of Mechanical Engineers, also known as ASME, has created a variety of requirements when it comes to labeling pipes. Accredited by ANSI, the American National Standards Institute, both organizations work together to provide consistent pipe labeling protocol for all industries that need it.

One of the best ways to learn about pipe marking standards is by looking at the ANSI/ASME A13.1 standard. This document will help with identifying information needed on a given pipe marking label, whether that be relating to colors, size of the label, symbols, or verbiage.

Updated in September of 2020, ANSI/ASME A13.1 has reiterated that ANSI/NEMA Z535.1, American National Standard for Safety Colors, as well as the Globally Harmonized System of Classification and Labeling of Chemicals, also known as GHS, play a part in the ANSI/ASME A13.1 standard. All three work together to provide the best advice on how to proceed with pipe marking in any facility.

Pipe Color Code from ANSI/ASME A13.1

The ANSI/ASME A13.1 standard for pipe colors is often used as a starting point for many facilities looking to improve their visual communication program. A standard set of colors paired with text and an occasional symbol help identify the substance in a pipe in a concise manner. Standardized colors and symbols help to eliminate excessive verbiage and prevent confusion when attempting to identify hazardous materials.

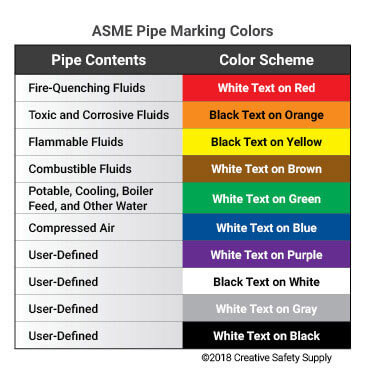

Standard A13.1 requires the following colors:

- Flammable and/or oxidizing - Any pipe that contains flammable fluids or vapor, or any kind of oxidizing agent, needs to have a label with black text on a yellow background.

- Combustible - Fluids that can ignite in the presence of a heat source, but are not flammable under normal circumstances, should be written with white text on a brown background.

- Toxic and/or Corrosive – Pipes containing fluids that can be toxic or corrosive should use black text with an orange background.

- Fire Quenching - Water or other fire suppression substances need to be labeled with white text on a red background.

- Other Water - Any water that is not intended to be used for fire suppression should be labeled with white text on a green background.

- Compressed Air - Any vapor or gas that is under pressure but does not fit in another category (such as compressed air) will be labeled with white text on a blue background.

There are also several options for user defined color codes. These include white on black, black on white, white on purple and white on gray. Whenever using these 'open' color options, make sure that they are followed throughout the facility to avoid any confusion.

Incorporate GHS Pictograms and Pipe Markings

There is even the option to include GHS pictograms on pipe marking labels to provide continuity and a maximum level of communication between workers and their environment. This happens usually in the event there is a larger container that has a standard GHS label, and it is connected to a pipe. If this route is chosen, the label must follow the A13.1 standard color scheme, as well as include the following information:

- The product identifier

- The pictogram(s)

- The signal word

- The physical, health, and environment hazard statement

Determining the Size of Pipe Labels

The size of a pipe label and the corresponding text size depend on the outer diameter of the pipe. The smaller the pipe the smaller the label, and likewise for pipes increasing in size. The goal of standardizing sizes for pipe labels is to maximize visibility for employees when passing by or when performing maintenance on a set of pipes. ANSI and ASME’s A13.1 standard describes the needed sizes of pipe labels ranging from pipe diameters of ¾ of an inch to 10 or more inches. The standard also states that pipes of less than ¾ of an inch require a permanent and legible tag.

Unique Pipe Marking Color Standards

When deciding what type of color standards to use for labeling a facility, it is important to know all the possible options. OSHA plant identification is an important part of determining what pipe marking standard you’ll need to follow. There are pipe marking standards for marine vessels, medical purposes, and wastewater treatment, to name a few. Unique environments may call for different color recommendations or even combinations of colors to keep employees safe and aware of their surroundings. The decision to use voluntary standards put forth by standard setting organizations like ANSI, ASME, or the NFPA, is always a prudent one, as the standards might still be mandatory by OSHA.

Carefully choosing which color standards to use is well worth the effort, as it will not be an easy feat to change later down the road. High quality pipe marking labels can last for years and if the standard within the facility is changed, replacement of all outdated pipe markings will be necessary.

Sea Vessel and Marine Pipe Marking: ISO 14726:2008

As mentioned above, one of those unique pipe marking situations revolves around marine vessels. These pipe color codes can often be quite different from those that are used on land due to the use of different chemicals, and other potentially dangerous environmental hazards for those in the vessel and the aquatic life surrounding it. For those reasons, keeping in line with marine pipe color standards is important for anyone that operates these types of vessels or facilities.

ISO 14726:2008 is the standard that corresponds with marine pipe labeling. Put forth by the International Organization for Standardization as a Draft International Standard, this document describes the process of identifying the contents of piping systems on ships and marine technology by using colors. Not only will following this standard help to ensure consistency across all marine vessels, it will also help vessels stay compliant globally.

Pipe Labeling for Wastewater Treatment Facilities

Pipe labeling for wastewater treatment facilities is much like pipe labeling for marine vessels in that there are often two colors used as identifiers on the same label. There are too many substances that flow through pipes in these types of industrial facilities to be able to use individual colors. Because of this, the colored band in the middle of the label is what differentiates, for example, raw sludge from sludge draw off.

The 10 states standards created by the Great Lake-Upper Mississippi River Board is a consensus standard that many facilities go by when looking to label wastewater treatment facilities. The standard document contains proven techniques for wastewater pipe labeling that improve safety for workers. Even though there are only ten states that are obligated to follow these written procedures, other states have caught on and started using them as well.

While these standards aren’t specifically mentioned by OSHA, it may fall into the general duty clause. This means OSHA can cite the employer for not providing the safest conditions for employees, of which is provided by these proven best practice methods for wastewater treatment pipe labeling.

IIAR Standards for Pipe Labels

The International Institute of Ammonia Refrigeration is the organization that handles ammonia pipe labeling. With such a dangerous chemical it’s critical to have the right labeling put into place for the safety of all employees. The most recent change the IIAR has made to their Bulletin No. 114 standard is the color of the ammonia pipe label itself. It must be orange instead of yellow.

The change came about because of the need for a more accurate description of ammonia itself. Yellow is specifically for chemicals that are classified as flammable. While gaseous ammonia is flammable in the right conditions, orange for “toxic” was a more appropriate choice, hence the change.

There are several other components to an ammonia pipe label aside from an orange background. Those include the need for:

- A physical state section that identifies whether or not the ammonia is a liquid or vapor within the pipe.

- A pressure level section that identifies whether or not the ammonia is at a high-pressure level or low-pressure level.

- An abbreviation section is needed to identify the type of ammonia in the pipe.

- A directional arow is needed to mark which way the contents are flowing.

Check out Creative Safety Supply’s free ammonia pipe marking guide to gather more information on how to create the safest workspace possible while around pipes that contain ammonia.

Training Employees on Pipe Marking

As with any safety improvement strategy, it’s critical to incorporate training into the overall plan. Without proper training, wasted time and a lack of safety can plague the facility. A lack in knowledge can even lead to delayed responses in emergency situations. Appropriate times for training employees on identifying pipe contents by labeling include:

- Onboarding - Whenever a new employee is hired to work with various pipe related tasks, they need to be trained in areas such as color charts, hazardous materials, and on emergency situations.

- Refresher - Refresher training annually for employees is a great way to keep them up to date on identifying the contents of pipes.

- Visual Reminders – Floor signs, wall signs, posters, and other visual reminders placed around a facility is a great way to reinforce what people already know. Whether it’s just covering the color guide or reinforcing more detailed information, these visual reminders are very effective.

Sharing pipe marking information with employees who will be in direct contact with pipes during everyday tasks will help you get the most out of any pipe marking plan.

Why is Pipe Labeling Important?

Whenever working with piping in any facility, it’s important to remember that the number one goal is ensuring everyone has the ability to work in a safe environment. By putting in the effort to label pipes, maintenance crews and employees will be much safer in terms of confidently identifying the contents of pipes within a facility. This is especially important when employees are dealing with hazardous substances during routine maintenance.

With that being said, obtaining high quality pipe labeling materials is not only a cost-effective choice for accident prevention, but it can also make employees’ jobs easier in terms of clear communication regarding hazardous materials.

Types of Pipe Labels

There are numerous best practice methods for labeling pipes and valves in a facility that are OSHA compliant, follow ANSI color codes, and use the ASME format. The two categories to choose from include vinyl material and valve tags. However, there are a handful of choices to pick from within those two categories.

Pre-printed Pipe Labels

Ordering pre-printed pipe labels are excellent for small projects where only a handful of labels are required. These are often commonly found pipe labels such as water pipe labels or ammonia pipe labels. Pre-printed pipe labels are made of the same material as you would get if you made them yourself on an industrial label printer. The only difference being that you don’t have to do any work!

Custom Pipe Marking

Custom made pipe labels are another story. There are substances out there that some websites don’t have in their image inventory. However, suppliers like us at Creative Safety Supply are more than happy to help facilities create their unique labels. Not only are we interested in your safety, but we want the custom label process to go smoothly so you get your labels as fast as possible.

Valve Tags

The best way to mark pipe valves is to use valve tags. These tags can be placed directly on the valve to help inform employees about its contents, the potential dangers associated with that chemical, etc. Valve tags are extremely easy to use and very effective. Facilities should ideally have them placed on every valve in the facility. This includes water valves, chemical valves, gas valves and any others present. Taking just moments to attach, the tag can remain in place for years without a problem.

There are many types of valve tags to choose from depending on the specific situation. Those options include:

- Stainless steel valve tags are durable and can withstand chemical exposure. AutoCAD programs can be used to engrave valve tags.

- Plastic valve tags are reusable even as pipe contents change. Vinyl stickers with the applicable information can replace the old information on a tag again and again.

Choosing the Right Pipe Marking Supplies

Picking durable, high-quality pipe marking supplies makes a pipe marking project much more manageable cost-wise. Excellent pipe marking vinyl or valve tag material should also last a long time in harsh conditions to allow the company to focus on other important projects without fretting over employee safety.

Piping often extends great distances throughout a facility which means many labels will be needed to outfit it properly. There are often options for pre-made labels as well as the option to make them in-house without having to wait on lead times or fix mistakes. Worrying about whether or not your pipe marking labels are ANSI code compliant wastes time, money, and labor. So why not start out with a supplier like Creative Safety Supply, the leader in visual safety for industrial environments.

The following are a few different types of labels that can be beneficial to any facility:

- Ammonia Markers - If the facility uses an ammonia refrigeration system it is essential to use approved ammonia markers. These markers need to meet the IIAR standards for abbreviation, physical state, marker body, pressure level, and flow direction.

- Pipe Marking Arrow Tape - Identifying the directional flow of the pipe’s contents is absolutely necessary. The easiest and most effective way to do this is by using arrow tape. As the name implies it is just tape with arrows pointing in one direction.

- GHS Pipe Marking Labels – These are especially nice to have in areas where hazardous chemicals are present. With the added hazard pictogram these pipe labels provide even more information than standard pipe labels would.

Creating Pipe Labels with an In-House Printer

Another great option is to obtain a label printer for the facility. The ability to print labels in-house ensures quick and easy access to labels when needed. They can print exactly what is required at the fraction of the cost of labels made and shipped by a supplier. For that reason, many companies choose this option, it saves on time and cost.

There are a variety of excellent pipe label printers on the market to choose from. Pipe labeling is not their only specialty, they can be used for making any types of labels or signs that a business needs to keep its employees safe. Check out the following three popular industrial label printers:

- LabelTac 4 - The LabelTac 4 is great for printing between ½" and 4" labels. It can create easy to read visual reminders for employees. This printer also comes with a lifetime warranty.

- LabelTac 4 PRO - The Pro version of the LabelTac 4 printer has an upgraded cutter, motor, and print head to ensure a faster and easier printing process. It also has an upgraded ribbon capacity allowing for longer times between changing out the ribbon supply.

- LabelTac 9 - This is the largest industrial label printer commonly used. It is for labels between 4' and 9' in width. It is made with die-cast metal and has a clear media view for easy use.

Conclusion

There is a lot to learn when it comes to pipe marking, but the more time that is spent learning about how to properly mark pipes, the better off a facility will be. When pipe marking is taken seriously, employees will catch on and continue to practice safe behavior. Taking the time to label pipes and valves correctly is well worth the effort for safety improvement purposes.

Consider taking a few minutes to watch this simple video about pipe marking and how it should be done:

Similar Articles

- A Guide to Pipe Marking Standards

- Pipe Color Codes – ANSI/ASME A13.1

- Pipeline Labeling

- Valve Tags: Guide for Pipe Identification

- ANSI Color Codes for Pipe Marking

- ANSI TIA 606-B Cable Labeling Standards

- Waste Water Treatment Labeling

- Labeling Electrical Conduits

- A Quick Guide to Underground Utility Labeling