Batch production is a concept that many manufacturing companies use to improve efficiency and reduce wasted time. The technique has the facility completing specific tasks all together, in batches, rather than completing a full process on its own. It is a popular alternative to the two other main production strategies, which are mass production and job production.

By working tasks in batches, less time is needed to change parts, move to different machines, or perform other activities. Each task can be completed in large numbers, which allows tasks to be completed more quickly than working them one at a time. Batch processing can be used for every aspect of the production of some items, or just for one step in the production process for others.

Advantages of Batch Production

This type of production offers many types of facilities significant advantages over other production techniques. Some of the most significant advantages include:

- Initial Capital Investment - Batch production allows one machine or line to produce multiple products, which can reduce the initial capital investments for many types of companies.

- Reduced Risk - Since a single machine or line is used for multiple products, there isn't the same level of risk that a facility running one product on one machine has. If one product type no longer sells, the other options are still viable.

- Good for Seasonal Products - Manufacturers that produce seasonal products often benefit from batch production. Making large batches of items and then switching the machinery for the next season is a very efficient production method.

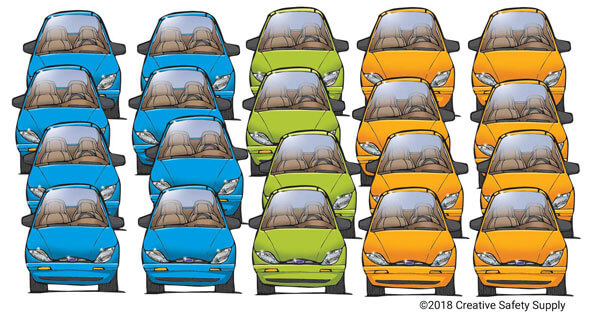

- Great for Cosmetic Changes - Batch production is also used when there are cosmetic changes to a product. The classic example is car manufacturing. The manufacturers will paint all of one colored cars in a batch, then switch to the next color, and cycle through all the color options in large batches to save time and effort.

Disadvantages of Batch Production

Batch production is not a good option for every type of manufacturing. These disadvantages need to be evaluated to see whether they make batch processing a bad option for a specific facility.

- Low Quantity Production - companies that build things that require only a small number at a time typically won't benefit from batch processing.

- Custom Made Products - When every item a facility produces needs to be custom made, it can't fully implement batch production. It may be possible, however, to use batching to complete certain parts of the production.

When is Batching Used

Batching is found in many manufacturing facilities. Industrial (or even home) bakeries use batching on a daily basis. The bakery will make large batches of one product, put them all in the oven to cook, and then package them all up. The dying of fabrics, leather, and other things is also done in large batches where things are dyed one color and moved on in the production, while other items are dyed another color. Another commonly batched process is film coating to sunglasses or computer screens, where it is possible to complete a task for hundreds, or even thousands, of items at a time.

Sources

- https://www.epa.gov/recycle/reducing-waste-what-you-can-do

- https://www.oneadvanced.com/news-and-opinion/what-is-batch-production-in-manufacturing/