Resources

Lean Manufacturing Articles

What is Toyota Lean Management?

Learn how to build a strong and efficient organization by implementing Toyota Lean Management principles to eliminate waste and improve business efficiency. …

Lean Thinking: The Foundation Of Lean Practice

Lean thinking is a business philosophy that maximizes customer value and eliminates waste, resulting in more growth and better results in any organization. …

Lean Safety | Understanding the Lean 6S Methodology

Implementing lean safety can result in safer and more efficient working conditions that minimize errors and require fewer corrective measures. …

Lean in Different Industries

The Lean methodology originated in the manufacturing sector, buit its core principles of continuous improvement, process optimization, and employee empowerment can be effectively applied across a wide range of industries. …

Understanding The 5S Methodology Implementation

This guide highlights important strategies to implement the 5S of lean. Discover the benefits, and utilize the tools to streamline the manufacturing processes. …

Applying Lean Principles in Healthcare

By applying lean methodology in healthcare, organizations have achieved significant improvements such as reducing errors in medical procedures, increasing patient satisfaction, and making healthcare more accessible while reducing expenses. …

Advanced Kanban: Optimizing Complex Systems

Kanban offers a simple and visual approach to managing complex systems that teams from different backgrounds can easily understand and implement. …

Heijunka (Production Leveling)

Heijunka is a Japanese word that means leveling. It consists of a lean manufacturing tool that helps companies level production and thus satisfy demand and reduce waste. …

Lean versus Six Sigma: Which is better for your business?

Successful businesses actively incorporate business management techniques such as Six Sigma and the Lean method in their operations to help reduce inefficiency and maximize profits, but which strategy is right for you? …

Control Charts: A Basic Component of Six Sigma

Statistical process control charts are a helpful visualization tool for recognizing deviation within a process. These charts help operators know when to take action. …

Peter Drucker: The Founder of Modern Management Studies

Known as the founder of modern management, Peter Drucker published 39 books and was an incredible resource as society transitioned into the 21st century. …

James Womack and the Creation of the Lean Enterprise Institute

Learn all about James Womack, the author of The Machine that Changed the World and the founder of the Lean Enterprise Institute, a notable figure in Lean history. …

John Krafcik and the Birth of the Term Lean

Learn all about where the term Lean came from in this article! You’ll read about John Krafcik and his initial studies on Lean production methods. …

William Edwards Deming: The Father of Quality Management

William Edwards Deming was incredibly influential in the world of quality management, and by extension, the development of Lean manufacturing. Learn about him here. …

Shigeo Shingo and the Importance of Operational Excellence

Learn all about Shigeo Shingo and the contributions he made to the world of Lean manufacturing, quality control, and overall operational excellence. …

The Origins of TPS

Explore The development of the Toyota Production System through the eyes of three of its most influential founders: Kiichiro Toyoda, Eiji Toyoda, and Taiichi Ohno. …

Frank and Lillian Gilbreth: Standardization, Ergonomics, and Lean Manufacturing

Frank and Lillian Gilbreth implemented motion studies to eliminate unnecessary movement during a process. They were the inventors of ergonomics. …

Henry Ford and Development of Assembly Lines

Learn all about the origins of Mass production and assembly lines in manufacturing with this article. It all started with Henry Ford. …

The Development of Scientific Management by Frederick Taylor

Scientific management was developed by Frederick Winslow Taylor to assist manufacturing facilities in creating a more productive workplace. …

Eli Whitney: A Key Player in the Development of Early Lean Manufacturing

Eli Whitney made some profound contributions to Lean manufacturing in terms of mass production and the popularization of interchangeable parts. …

Autonomous Maintenance: The Key to a Healthy TPM Program

Autonomous maintenance is an important part of Total Productive Maintenance strategies. This is done by handing over simple maintenance tasks to machine operators. …

A Look at Training Within Industry (TWI)

Training within Industry, or TWI, uses a series of training modules to develop leaders within a business that then train new employees quickly and effectively. …

A Complete Guide to QR Codes

QR codes can be put to use in a variety of instances due to their ability to hold an astounding amount of information in comparison to other more common barcodes. …

What is a CMMS? (Computerized Maintenance Management System)

A CMMS allows for the users to easily keep track of information needed for preventative maintenance to keep equipment and workflow running as intended. …

What is Logistics Management? (Supply Chain)

Logistics management ensures that the right product is delivered to the right customer, at the right price and the right time. Learn how logistics can help you reduce costs and improve efficiency. …

Understanding the Principles of Lean Construction

When Lean techniques are incorporated into traditional methods of construction, a project is completed more efficiently. These are the main principles behind Lean Construction. …

Understanding Design for Six Sigma (DFSS)

DFSS is an improvement technique that uses the DMADV approach to ensure that a product or service meets customer expectations as it is originally introduced to the market. …

Supply Chain Management (SCM)

A smooth and efficient supply chain ensures quality products, customer satisfaction, and a positive reputation. These are the essential components to effective supply chain management. …

Automated Guided Vehicle Lane Marking

AGVs exist in large facilities to help with consistency and safety. Used for manual labor, AGVs are able to reduce steps in processing to focus on other priorities. …

6S: Safety

Safety is the additional sixth step to the traditional 5S method. A company that implements 6S focuses on improving organization and efficiency, with an emphasis on safety throughout each step. …

Military Equipment [Condition Tags & Labeling]

Military equipment includes weapons, aircraft, vehicles, and personal gear that was intended for use by the Armed Forces. A wide variety of materials falls under this classification, and proper labeling of their condition is essential. …

Quality Control

Quality Control helps ensure products are meeting customer needs and reduce the risk of product defects. Let this article help get you started. …

Kaizen and Lean Manufacturing

Going “Lean” is all about continuous improvement. Kaizen gives Lean manufacturers the tools and strategies they need to identify wastes in their facility and effectively eliminate them. …

A Brief History of Kaizen: The Key Players

Kaizen has been shaped over the years by an automobile manufacturer, American statisticians, influential businessmen, and more. We explore who had a hand in creating Kaizen and how it has developed into the philosophy we know today. …

An In-Depth History of the Kaizen PDCA Cycle

Lean organizations focus on improving all parts of a process from start to finish in order to increase the quality of the results. Through the use of specific cycles (like PDCA), organizations can improve the processes and end products. …

Quality Management Systems (ISO 9001:2015)

ISO 9001: 2015 is a standard that outlines and defines requirements for a quality management systems. This QMS certification allows companies to demonstrate to clients that they take quality and efficiency seriously. …

Implementing Kanban

Kanban’s inventory system has transformed the way the world manufactures. This article outlines how to implement Kanban successfully and efficiently. …

DMAIC Cycle

The DMAIC cycle is the foundational method of Six Sigma, the Lean manufacturing method that radically reduces defects in production and infinitely improves efficiency. Learn how to implement Six Sigma into your facility with DMAIC. …

Safety Committee

Implementing a safety committee can help improve the overall safety of your company. Discussing safety concerns and resolving them will keep your employees safe. …

Quality Control in Manufacturing

Quality control in manufacturing is essential to maintaining a good customer base and keeping rework costs down. …

5S Lean Training

If you’re new to the concept of 5S, you’ve probably feel confused. This article aims at providing clarity and setting you on the path toward understanding 5S and Lean. …

Kanban Production System

Kanban Production Systems are an organizational system that produces big results by taking a series of small steps. Find out more... …

Barcode Labeling

Barcode labeling can help improve efficiency and overall accuracy when working with individual items. Learn how barcode labeling can help improve your business today. …

Six Sigma Certification

Are you wanting to learn more about Six Sigma certification? Review this basic information on what it takes to become Six Sigma certified. …

Critical Path Method

The critical path method (CPM) is a tool for planning and managing projects. The method can help you create and execute a project schedule, and it’s designed to maximize efficiency. …

Mass Production

Mass production is simply the manufacturing of a large number of identical or very similar products. This type of production has been around for a long time, and it has its advantages and disadvantages. …

House of Lean

The house of lean involves strategic planning and understanding to establish results of efficiency, safety, and process improvement. …

What is QCDSM?

QCDSM: Quality, Cost, Delivery, Safety and Morale. Learn how this simple lean principle can help your business. …

8 Wastes of Lean [A Guide to Manufacturing Wastes]

The 8 Wastes of Lean is a much-needed update to the what the Toyota Production System called the 7 Wastes of Lean. Fighting these wastes head on will help your facility run more smoothly and efficiently. …

Six Sigma Belt Levels [Hierarchy of Certification]

Have you ever wondered what the Six Sigma belt levels are? Learn the requirements for each belt level and what it will do for your organization. …

Supply Chain Integration

Supply chain integration refers to the process of integrating all parts of fulfillment into one single system. Learn the steps to get your supply chain integrated into an easy-to-manage system. …

Organizational Development Process

Organizational development process is an improvement methodology designed to take known problems and implement changes in order to overcome them. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

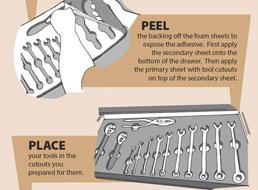

Tool Storage Ideas

Lean manufacturing emphasizes organization, but it can be difficult figuring out just how to get started. This article lays out some common and effective ways of getting organized quickly. …

Six Sigma Black Belt

For people wanting to master the six sigma methodologies, earning six sigma belts is the best way to master the principles associated with Six Sigma. …

Six Sigma Green Belt

Earning a Six Sigma green belt is the first step toward mastering Six Sigma methodologies. Learn how to get started here. …

Value Stream Mapping (VSM Analysis)

Value stream mapping (VSM) gives a comprehensive look at a business’s production process. Once a business has their process mapped out, it’s easy to identify the places where waste happens. …

What is Jishuken?

Are you a leader looking to understand the benefits of Jishuken? We breakdown the definition of Jishuken and how it can improve efficiency in your workplace. …

Lean Healthcare (Principles for Improvement)

Implementing lean healthcare in the medical field will lead to improvement in overall performance and patient satisfaction. …

What is a Kaizen Event? [Planning and Execution]

Learn how to implement a kaizen event and improve your lean manufacturing strategy. …

Floor Marking for Facility Safety

The best way to enhance safety is keeping workers informed, and floor markings are the most reliable, durable method of ensuring that everyone is aware of potential hazards. …

Perpetual Inventory System

Using a perpetual inventory system is a great way to keep track of inventory, ordering, and other related tasks in order to keep your business running efficiently. …

Industrial Floor Marking Guidelines

OSHA doesn’t offer much guidance on how floor markings should be installed, so we’ve compiled some helpful tips and best practices to ensure your markings are useful, straightforward, and helpful to everyone in your facility. …

Floor Marking For 5S

Inexpensive yet endlessly practical floor markings can drastically simplify your 5S efforts, while saving you time and money. Learn more in our latest article. …

Asset Tags: Tracking Inventory & Equipment

A simple yet powerful organization tool, asset tags reduce theft, enhance inventory management efforts, and make it easier for employees to find exactly what they need exactly when they need it. …

Theory of Constraints

Whether you know it or not, something is holding your business back, and the Theory of Constraints can help you find it. …

Floor Marking for Fire Extinguishers

Use floor markings to make sure you can find the fire extinguisher and that it is not blocked in an emergency. …

Calculating Overall Equipment Effectiveness (OEE)

Are your lean and 5S efforts making a difference? Crunch the numbers on OEE to find out! …

Total Productive Maintenance

Learn how you can reduce downtime, improve efficiency, and enhance employee morale all in one fell swoop with Total Productive Maintenance. …

8D for Problem Solving

The 8 Disciplines (often seen as the acronym “8D") is a problem-solving method initially developed by the Ford Motor Company to resolve a wide variety of problems in any professional environment. Find out how the 8D method can benefit your workplace. …

What is Lean Logistics?

Lean logistics is a detailed implementation or organization of an operation that is more complex in nature than what you see in standard lean strategy. …

Kano Model (Analysis & Diagram)

Using the Kano model is beneficial when evaluating what your consumers like, need or expect from your product or services. Learn more... …

Statistical Process Control (SPC) in Manufacturing

Statistical Process Control also known as SPC, is a term used in quality control. Find out how you can use this continuous improvement method. …

Bottleneck Analysis

Learn to avoid hang ups that lead to bottlenecks with these helpful tools and tactics to improve quality and efficiency. …

Quality Circle

Quality circle is a group of employees within the same job role that collaborate together to discuss ways to fix or improve processes. Learn more › …

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace. …

Warehouse Management

Proper warehouse management can dramatically improve both efficiency and safety. This article covers everything you need to know. …

Six Sigma Principles

Find out how to properly implement six sigma principles to promote success in your business. …

5 Lean Principles for Process Improvement

Learning the basics about the lean process is essential when implementing continuous improvement changes. We have broken down the lean process so its easy to understand. …

Fault Tree Analysis

Understanding fault tree analysis can help you find the root cause to an issue to help it become resolved. Learn about implementing fault tree analysis in your industry. …

Toyota Production System (TPS & Lean Manufacturing)

The Toyota Production System, or TPS, brings improved organization to a facility, reduces waste, and can improve the bottom line of companies that adopt it. …

Introduction to Process Mapping

Process Mapping is used in many types of businesses to help companies streamline their production, increase profitability, reduce waste, and much more. …

Cross-Docking (Understanding Efficient Warehouses)

Cross docking is a logistical strategy where products and materials are unloaded from one inbound sourceand then immediately moved onto outbound transportation with as little storage time as possible. …

Balanced Scorecard [Definition + Examples]

A balanced scorecard is an effective management system that helps organizations better accomplish their goals and can be used effectively any type of business. …

Continuous Improvement (A Kaizen Model)

Facilities that focus on continuous improvement become more competitive over time and can maintain their advantages in their industry, but only if the improvement efforts are done correctly. …

Process Cycle Efficiency (PCE)

Process Cycle Efficiency is a metric commonly used by those following Lean and/or Six Sigma principals. It is calculated by taking value-added time and dividing it by lead time. The answer is a percentage, and the goal is to be as close to 100% as possible. …

Value-Added vs. Non-Value-Added Activities

The terms value-added and non-value-added are often used when evaluating changes in products, workflow production and process improvement. Categorizing activities will help identify what activities should be maintained and which ones should be adjusted or eliminated. …

Batch Production

Batch production involves the facility completing specific tasks all together, in batches, rather than completing a full process on its own, to help improve efficiency and reduce wasted time. …

FOCUS-PDCA

FOCUS-PDCA is a business strategy designed to help improve processes. It is an acronym for the steps and actions that need to take place during the process improvement period. …

How to Implement 5S in an Organization

It takes significant effort to implement a proper 5S program, but following the right steps will drive success and help the process go smoothly. …

5 Lean Manufacturing Tools that Work

These five lean manufacturing tools are essential for making your lean journey a success. …

Getting Started with Kaizen

Proper training is key for getting started with Kaizen and on the road to continuous improvement. …

Floor Marking Ideas for Warehouses

Warehouse floors provide an opportunity for visual communication. Find out what floor signs, tapes, and shapes you can use. …

Genchi Genbutsu

Genchi genbutsu, a Japanese term meaning “go and see,” can change how managers and company leaders interact with the workplace. …

Chaku Chaku

This Lean concept can improve the way manufacturing cells function by organizing space in specific ways. …

Hoshin Kanri

This Lean term for “policy deployment” can help keep everyone in an organization on the same page. …

Lean Supplies

Learn what supplies and tools you can use to make Lean manufacturing efforts successful. …

What is a Gemba walk? [Lean Manufacturing Definition]

This Japanese word for "the real place" can change the way managers approach employees and their work. …

Kanban Training and Research

A kanban system uses visual cues to trigger actions. Find out how it can regulate production. …

Lean Manufacturing [Techniques, Solutions & Free Guide]

This business model seeks to eliminate waste and increase value in work processes. …

The 5S System [Lean Manufacturing Methodology]

One of the most comprehensive pages you will find on 5S. …

Tool Box Organizers – 19 Tips & Hacks for Your Tool Box

Use these tool foam organizer tips and hacks get your workspace in order and simplify your life. …

Kaizen (Lean Continuous Improvement)

The concept of Kaizen will help any organization through continuous improvement. …

Lean Manufacturing Questions and Answers

What are some Examples of Lean Manufacturing From Leading Companies?

Lean manufacturing is utilized by many leading companies across various industries to improve their efficiency and cut down on waste. By enhancing internal processes, this in turn provides a better service to customers and helps the brand grow. In this article, we discuss some examples of well known international brands who are successfully utilizing lean… …

What are KPIs?

Navigating the business world in the modern world isn't just about having a good product or service—it's about leveraging data to optimize and excel. This is where Key Performance Indicators (KPIs) come into play. Our comprehensive guide deciphers the complex language of KPIs, helping you understand their importance and how to use them effectively in… …

How does Lean Manufacturing improve quality?

How does Lean Manufacturing improve quality? Lean manufacturing is a fundamental methodology applied in the manufacturing industry and beyond; its proven benefits have encouraged companies in fields like healthcare and finance to adopt it, as well. It’s a production improvement strategy that aims to boost customer value by eliminating waste and streamlining work processes. But how is… …

How is Lean Manufacturing used today?

How is Lean Manufacturing used today? Lean manufacturing is one of the most used production methodologies in the manufacturing industry. But because this framework has been around since the 1950s, many people have doubted its ability to adapt to a more modern world rife with technology and new industries. That said, Lean manufacturing continues to be relevant,… …

Is Lean Six Sigma useful?

Is Lean Six Sigma useful? Lean manufacturing–including the 5S methodology–and Six Sigma are two organizational methodologies that help businesses increase productivity and provide better customer value. Both are different, but their effects and benefits are similar enough that people sometimes confuse them with each other. This brought about a hybrid concept called Lean Six Sigma, which combines… …

What does Lean Manufacturing consist of?

What does Lean Manufacturing consist of? The manufacturing industry deals with a lot of waste every day. And whether it’s excess inventory, unnecessary movement, or unused talent, the result is hampered productivity. Lean manufacturing, including the 5S principles, aims to combat this through five key elements: identifying value, mapping the value stream, creating flow, establishing a… …

What are the benefits of Lean Manufacturing?

What are the benefits of Lean Manufacturing Lean manufacturing is a production methodology that was first implemented in the manufacturing industry, specifically in the Toyota Production System (TPS). But its proven track record of improving business efficiency and increasing customer value has made it popular among organizations outside the field, including healthcare and other services. The technique… …

What's the difference between Traditional and Lean Manufacturing?

What's the difference between Traditional and Lean Manufacturing? For years, the manufacturing industry has centered around creating products in anticipation of having a market for them to be sold. Sales forecasts have driven operations, and manufacturers have stockpiled inventories in the hope of that demand being realized. Do all customers really want the same things? Is mass… …

What Are Lean Management Principles?

What Are Lean Management Principles? Lean management enabled Intel to reduce its minimum product launch time from fourteen weeks to just ten days. It also helped Intel’s operations stay profitable when energy prices skyrocketed. Similarly, it has helped several large corporations (such as the Kimberly-Clark Corporation and Nike) achieve remarkable tenfold increases in workplace productivity. What Is Lean… …

How do I learn Lean Manufacturing?

How do I learn Lean Manufacturing? Lean manufacturing is an excellent methodology to eliminate wasteful processes, simplify manufacturing, and deliver high value to customers. However, Lean implementations fail at an astonishing rate of 70% in the United States. Lean principles can be difficult to implement, with challenges ranging from the high cost of transition, organizational resistance, and… …

How do I apply Lean Management Principles?

How do I apply Lean Management Principles? Inefficiency in daily operations can easily reduce your annual revenue by 20% to 30%. Say you’re currently making $72,000 per year–there’s a chance you could increase that amount by $15,000 to $22,000 by improving your manufacturing processes! With Lean management principles, you can turn the tables around. Instead of missing… …

When should a firm adopt Lean Manufacturing?

When Should a Firm Adopt Lean Manufacturing? If your workplace has processes that don’t always produce consistent results, don’t confront frequent errors, and are often redundant, you may have considered an overhaul. To improve efficiency at your company, you may have looked into Lean manufacturing. Today, we’ll discuss Lean manufacturing and when it’s time to implement it.… …

Is Lean Six Sigma Still Relevant?

Is Lean Six Sigma Still Relevant? Understanding methods that can increase productivity, like the 5S principles and Lean Six Sigma, is vital to running an effective workplace. When a firm adopts Lean manufacturing, for example, they become safer, more efficient, and less wasteful. Lean Six Sigma is a similar method, but you might not have heard about… …

What is a Lean Six Sigma Yellow Belt?

What Is a Lean Six Sigma Yellow Belt? If you’re looking to improve your organization’s processes and efficiency, you may have looked into 5S training and Six Sigma. Implementing both of these programs can change the trajectory of your company, so it’s worthwhile to learn more about them. Today, we’ll talk about a method that can help… …

What is the difference between Lean Manufacturing and Six Sigma?

What is the difference between Lean Manufacturing and Six Sigma? The rising competition in business has kept business owners and managers relentlessly looking for new and more effective ideas on how to eliminate the waste of important resources in their business without compromising the quality of their products. Some of the common managerial strategies being implemented in… …

What is Lean Six Sigma?

What Is Lean Six Sigma? Lean Six Sigma is an approach that merges Lean and Six Sigma to improve processes in a manufacturing facility. The Lean approach became popular in manufacturing after Toyota embraced it to improve its manufacturing processes. It focuses on enhancing manufacturing and transaction processes by getting rid of waste to offer your customers… …

What is a Lean Six Sigma Black Belt?

What Is a Lean Six Sigma Black Belt? A Lean Six Sigma (LSS) Black Belt is a professional who has undergone training in the Lean Six Sigma policy to gain the necessary skills and knowledge to transform their organizations through process improvement approaches. The Lean Six Sigma approach enables team leaders in organizations, especially in the… …

What Are Blue Collar Jobs?

In an era where automation and artificial intelligence regularly dominate headlines, there's an undeniable charm and vitality found in the hustle and determination of blue-collar jobs. They are the foundation that built our society and continue to keep it running smoothly. Prepare to strap on your work boots, roll up your sleeves, and plunge into… …

How Can Manufacturing Become More Meaningful?

In the dynamic landscape of 2023, manufacturers are not just making products; they're crafting meaning and value for an ever-evolving consumer base. Harnessing the power to create lasting value in what we manufacture is now more essential than ever. Brace yourself, as we dive headfirst into navigating this new frontier where meaningful manufacturing becomes the… …

What is the Definition of Lean Manufacturing?

There is no set definition of lean manufacturing as different books, websites, and people describe it slightly differently. Everyone can agree, however, that it is a production method that is used to help minimize waste and cut down the amount of time that it takes for things to go from the supplier to the customer. The… …

What is the Lean Manufacturing System?

The lean manufacturing system is a set of strategies focused on improving the production process in many different areas. Lean methodologies are used throughout almost every industry, so the lean manufacturing system is a sub-category of lean concepts in general. Manufacturing is where people are generally most familiar with lean concepts though since a constant… …

Who Invented Lean Manufacturing?

The term lean manufacturing really got its start in the early 1990s in a book called The Machine that Changed the World, written by James P. Womack, Daniel T. Jones, and Daniel Ross. They wrote about how different manufacturing systems are used throughout the world and really took the industrial revolution to a whole new… …

What is Lean engineering?

Since its development, the guiding principles of Lean manufacturing have demonstrated to be successful for businesses in virtually any industry. From hospitals implementing Lean company-wide to small offices holding Kaizen events, Lean is proven for improving efficiency and reducing costs. One definition of Lean engineering is as a “holistic approach” that can help improve the efficacy… …

What is Lean construction?

Lean principles have been growing in popularity within the construction industry as more and more jobsites are incorporating Lean techniques into traditional methods of construction. Although projects in construction are known to be unpredictable and likely to face a variety of disruptions to the workflow, construction companies are finding success by adopting Lean tools and… …

What is the difference between JIT, Lean, and TPS?

To put it most simply, the Toyota Production System (TPS) is the primary influence of Lean manufacturing which operates using a just-in-time (JIT) system. What is TPS? As its name suggests, the Toyota Production System was a production system created by the Toyota Motor Corporation. TPS was developed in the 1950s and 1960s with the goal… …

What is 3M in manufacturing?

Developed by Toyota, 3M are three different types of waste that businesses can eliminate to become more “Lean”. Muda refers to common manufacturing activities that do not create any value for the customer. The Toyota Production System originally identified seven kinds of muda, known as TIMWOOD: Transportation: Unnecessary movements of the product between processes results in… …

How can Lean affect the supply chain?

A “Lean” supply chain is a supply chain optimized to deliver products quickly and with little to no waste. From Lean tools to the philosophy of continuous improvement, businesses can reduce costs by translating the principles of Lean manufacturing to the supply chain. There are two main tenants of Lean manufacturing that can be applied to… …

What is TQM?

TQM, also known as Total Quality Management, is known to be a customer satisfaction-based management approach for products, services, processes, and the culture that the employees uphold at the business. One of the main goals of implementing this strategy in the workplace is to eliminate defects and waste during production. To do this, there are… …

What is SIPOC?

SIPOC stands for “Suppliers, Inputs, Process, Outputs, and Customers.” SIPOC is represented in a straightforward diagram that’s a useful process improvement tool in Lean manufacturing. These diagrams are often used in the Six Sigma methodology to help reduce defects and make a process more efficient. A SIPOC table uses five columns and represents a manufacturing… …

How are fishbone diagrams created?

Fishbone diagrams, which are also known as Ishikawa diagrams, were originally created by Kaoru Ishikawa. They are used to show the causes of specific events. While there are quite a few ways that they are used, it is most commonly a tool for product design and quality defect prevention. They get the name from the… …

What does FTA stand for?

FTA stands for fault tree analysis, which is a deductive diagram that is used to visually depict where and how a production system may fail. FTA aims to map out the combination of human error and equipment breakdowns that may lead to an undesired event. It also helps to mitigate these mistakes before the end… …

What is 3P?

3P is a shorthand way of referring to a method that is set up to help make changes and improvements in the production process. The 3 P’s in this system are, “Production, Preparation, and Process.” The concept behind this system is to help to accomplish rapid, integrated prototyping of products as well as processes. This… …

What is SMED?

SMED is an abbreviation for Single Minute Exchange of Die. This is a process that is used to help reduce the setup (or changeover) time and effort that is needed by identifying elements as either internal or external for the operating time of a machine. Any elements that can be exchanged externally while the machine… …

What is JIT?

JIT is just-in-time manufacturing. It is considered to be a pillar of Lean manufacturing and the Toyota Production System; as a production method, it focuses on initiating action based on real-time customer demand rather than forecasted demand. With JIT, production is scheduled per an actual customer order that triggers a sequence of events. For example,… …

What does TPS stand for?

TPS stands for the Toyota Production System, a manufacturing model that aims to eliminate waste and achieve the most efficient methods of production possible. It helps bring organization and improvement, and ultimately enhances the bottom line while respecting workers and meeting customer needs. This system has changed the way production operates around the world; although… …

What is Parkinson's law?

Parkinson’s law is a very common adage that states, “work expands so as to fill the time available for its completion.” This can be seen in action in many different workplace environments. If someone has to work for 8 hours per day, it will take them 8 hours each day to complete the work they… …

What do the letters in the acronym DOWNTIME refer to in Lean Methodology?

Lean methodology is designed to help companies find and eliminate waste from the facility. To help with that goal there are many different strategies, one of which is known as DOWNTIME. This is actually an acronym that is set up to help people think about the 8 different types of waste that may be present… …

What is PMBOK?

PMBOK is an acronym that stands for Project Management Body of Knowledge. It is a set of standards used for project management. These standards are generally found in a book called, “A Guide to the Project Management Body of Knowledge,” which is updated over time. The sixth, and most recent, edition of this book was… …

What does WIP stand for?

WIP stands for Work In Progress. It is a commonly used acronym in manufacturing, project management, as well as a wide range of other industries. In simple terms, it simply refers to any task or project that is currently being worked on. It can also be referencing an area where work is actively being done,… …

What does KPI stand for?

KPI stands for Key Performance Indicator. This is a measurable value that is used to demonstrate just how well a company is achieving their most important business objectives. Businesses of all types use KPIs when measuring their success in various areas. These measurements can be used either at a corporate level or more narrowly based… …

What is a GANTT chart?

Gantt charts are used to track progress on a project and make sure everything remains on schedule. It is a form of a bar chart that was invented by Henry Gantt around 1910-1915. The original form of these charts was quite simple and only used to monitor progress of various steps in a project. Over… …

Is mass production considered Lean?

Mass production, traditionally, has not been a Lean strategy for manufacturing. Instead, Lean manufacturing heavily relies on a pull system (just-in-time) rather than a push system (mass production). The difference between these two methods lie in the scheduling of production. In mass production systems, customer demand is predicted based off data, shopping trends, etc., and… …

How do I Process Map?

Process mapping is seen as the essential first step to any process improvement effort and is a powerful tool in for any Lean organization. It will give managers a better understanding of processes and serve as a comprehensive overview of the current state of processes. Process mapping refers to the practice of communicating the process… …

What are the 5 Whys?

When problems pop up in the workplace, it can be tempting to fix it quickly. However, not finding and addressing the root cause of the issue can lead to recurring mistakes and future problems. An easy way to complete a root cause analysis and uncover deeper issues is with the Five Whys. Sakichi Toyoda is credited… …

What is Heijunka?

A critical element to the Toyota Production System and Lean manufacturing is Heijunka, a Japanese concept translating to mean “production leveling.” The goal of Heijunka is to smooth out production to a constant and predictable rate, reducing Mura (unevenness) which will in turn reduce Muda (waste). Heijunka is a technique that allows you to best… …

What are fishbone diagrams?

Fishbone diagrams are a Lean problem-solving tool used to identify the root cause of an issue. The goal is to reveal relationships between variables Performing a root cause analysis is one of Lean’s most important methods for problem solving and implementing corrective actions that will prevent the problem from happening again. You may also see these… …

What is value stream mapping?

Value steam mapping is a Lean method used for reducing waste, planning improvement activities, evaluating progress, and more. The Toyota Motor Company is credited with developing and implementing the original VSM template, a represent of materials and information flowing through the facility. The goal of creating a VSM is to look at the current state… …

How is OEE calculated?

Overall equipment effectiveness (OEE) is a Lean metric considered to be the gold standard for evaluating manufacturing operations. OEE is a percentage representing the amount of manufacturing time is truly productive; higher OEE scores means production is closer to meeting its full potential. Companies calculate OEE to uncover losses, identify opportunities for improvement, and track… …

What is just-in-time (JIT) manufacturing?

Just-in-time (JIT) manufacturing is a term used synonymously with the Toyota Production System (TPS), the methodology that Lean manufacturing is largely based upon. The exact details of JIT’s origins are a bit unclear but can be traced back to post-World War II Japan. The term JIT is so interchangeable with TPS because it was during… …

How do I create a balanced scorecard?

Balanced scorecards are a Lean tool used to connect day-to-day operations with the big picture goals of an organization. It is a system that helps prioritize projects and products while measuring a maintaining the progress to meet strategic targets. Each task and every action an operator or assembly line worker completes should, in some way,… …

How do I create a value stream map?

Value stream maps represent the flow of materials, work, ad information through the facility and are a Lean tool used to identify areas of improvement. While creating a value stream map can be simply drawn on a piece of paper, there are a few best practices and elements you should be aware of before you… …

What is Muda?

Muda is a Japanese term meaning futility, wastefulness, or uselessness. In the context of Lean manufacturing, muda is a key concept as one of three types of waste (muda, mura, and muri) identified by the Toyota Production System. Muda refers to the seven wastes commonly found in Lean manufacturing as identified by Taiichi Ohno: Transportation:… …

What is 8D?

The Eight Disciplines (8D) of problem solving is a model used to effectively identify and solve recurring problems. While most Lean tools are derived from the Toyota Production System, 8D was actually developed by the Ford Motor Company. 8D is made up of eight steps for problem solving, but many choose to include an additional step… …

How do I calculate Takt time?

Takt time represents the average amount of time needed to adequately meet customer demand while not operating over capacity. Takt time is calculated with the following equation: Takt time = Ta ÷ D In this formula you need the total production time (Ta) and the rate of customer demand (D) in order to find Takt time. Total… …

What is a value stream?

A value stream represents all of the activities, from start to finish, that take place in the production process. Value stream mapping, mapping the flow of goods from the supplier all the way to the customer and detailing all the steps involved in the work process is a popular tool in Lean manufacturing. Breaking down… …

What is a balanced scorecard?

Balanced scorecards are a management system often used in Lean workplaces. This strategy works to drive performance while keeping everyone in the organization accountable. Balanced scorecards are a great tool for monitoring day-to-day work and evaluating progress in the context of “the big picture.” High-level aspects of a company, or the big picture, are included in… …

What is poke yoke?

Poka yoke is something you might hear when talking about Lean manufacturing. It is a Japanese term meaning “mistake proofing,” and was developed as part of the Toyota Production System. Shigeo Shingo, an engineer at Toyota, is credited with the conceptualization of poka yoke, a technique for building and engineering mechanisms into a process that… …

What is the SCAMPER method?

SCAMPER is a tool used to ignite and foster creativity in collaboration. It is used in classrooms by students, in conference rooms, offices, and so many more places. First proposed by Alex Faickney Osborn in 1953 and later developed by Bob Eberele in 1971, SCAMPER was created as a way to enhance students’ knowledge and… …

What is a perpetual inventory system?

A perpetual inventory system, sometimes called a continuous inventory system, is a method for managing inventory with real-time updates about what a facility has on hand. The system is updated right when materials come in or when an order goes out, consistently reflecting accurate inventory information. Perpetual inventory systems are the opposite of periodic systems,… …

When was Lean manufacturing invented?

Although Lean principles can be traced back to the 18th century, in order to understand the Lean business model used today you have to look at the relationship between American and Japanese manufacturers. American business magnate Henry Ford revolutionized the manufacturing production process by developing what he called flow production. Automobiles being manufactured at this time… …

What is the goal of Lean?

Lean thinking is used by companies who are looking to improve efficiency and eliminate wastes. The ultimate goal for Lean manufacturing is to create quality products that satisfy the customer and meet demand with as little resources as necessary. Lean manufacturing came to popularity in the 1990s and derived most of its principles and philosophies… …

What is takt time?

Takt time is a commonly used metric in Lean manufacturing for effectively managing a pull system. The concept was first used as a project management tool by the German aircraft industry, eventually becoming popularized by Toyota and the Toyota Production System. Takt time is the maximum amount of time needed to completely manufacture a product… …

What is process mapping?

Process mapping is a tool used to show the sequence of steps within a business process from beginning to end. Mangers and Lean practitioners use process mapping to evaluate workflow, look for areas of improvement, and identify non-value-added activities. Whether you work in a restaurant or a manufacturing facility, a process map can be a… …

What is cross docking?

Cross docking is a logistical strategy used in supply chain management that looks to improve efficiency through warehousing and distribution efforts. In traditional manufacturing companies, products are stored in a warehouse or other location often for long periods of time waiting for delivery. In Lean manufacturing however, that storage time and space is considered wasteful… …

What is lead time?

In the most basic sense, lead time is the amount of time elapsed between a customer placing an order to when that order is sent out for delivery. In manufacturing, lead time is made up of three different stages: Preprocessing Lead Time: Preprocessing or planning lead time, is the time after an order has been… …

What are bottlenecks and how can I fix them?

Simply put, bottlenecks are areas in the manufacturing process where work is held up. It’s a stage within the process where requests outnumber the throughput constraint, causing an interruption to the workflow and delays across the entire production process. For instance, a company manufacturing cars sends four cars every hour to the painting station. However,… …

How does someone become certified in Lean manufacturing (Six Sigma)?

While a company does not have to have anyone certified in Lean manufacturing (Six Sigma) to implement Lean manufacturing strategies, it will certainly help. Those who become certified will learn the processes so that they can be implemented successfully. In addition, the certification process requires the individual to gain real, hands on experience with Lean… …

Which automobile company initialized Lean manufacturing?

The basic concepts of Lean manufacturing have a very long history, going back many hundreds of years. These concepts include waste reduction, improved efficiency, and more. Lean as we see it today, however, really got its start in the early 1900’s. While many people credit the Toyota Motor Company for most of the major manufacturing… …

Are people or processes more important in Lean manufacturing?

When implementing Lean manufacturing in a facility most managers will notice that there is endless information about the processes used to make it a success. There is no doubt that following these processes is essential for Lean manufacturing, which can lead some people to believe that it is the processes that are most important, not… …

What is the Lean methodology?

Lean methodology, whether used in manufacturing, health care, or any other industry, is a concept where a business attempts to create a flow of value to the customer through specific concepts. Most people associate Lean with waste elimination, and that is a big result, but the real goal behind Lean is providing your customers with… …

Who should be involved in Lean manufacturing?

Any facility that is looking to implement or expand Lean manufacturing will have to take a close look at who should be involved in the process. The fact is, Lean manufacturing will require everyone in the facility to contribute in some way. While there may be a few people who act as the Lean leadership… …

How does Lean manufacturing eliminate waste?

The main reason companies look to implement Lean manufacturing strategies is to help them eliminate waste. Cutting out waste will reduce their expenses and maximize profits so that they can be more competitive, and therefore more successful. Understanding how this methodology can eliminate waste will help to determine the benefits that a given workplace will… …

What is needed in a Lean 5S toolkit?

In Lean workplaces there will typically be one person, or a small group of people, who are responsible for ensuring the standards for Lean are followed. They will, of course, have help in making changes, finding root causes, and measuring success, but keeping the Lean 5S strategies moving forward will rest on their shoulders. This means… …

Is Kaizen an alternative for Lean Six Sigma?

Facilities that are looking into ways to make improvements they will undoubtedly run into a lot of different options, which can lead to confusion. Two of the most common terms used in this field are Lean Six Sigma and Kaizen. At first glance, many people think of Kaizen as an alternative to Lean, or even… …

Where do I start with Lean manufacturing?

Any company that is looking into implementing Lean manufacturing standards is going to run into one significant obstacle. Where to start. While there is endless documentation and recommendations on ways to perform Lean manufacturing techniques, there really isn’t very much out there that can help take these methodologies from an idea into production. Fortunately, it is… …

What are Lean manufacturing tools?

Lean manufacturing facilities use a variety of tools and strategies to maximize efficiency and eliminate waste. Unlike strict process improvement methodologies, Lean is more of a high-level strategy or concept that will take advantage of what other systems have to offer. Part of Lean manufacturing is being able to determine which tools are the right… …

What are principles of Lean manufacturing?

Any company that is thinking about implementing Lean manufacturing strategies will want to take some time to learn about the main principles behind this methodology. While most people simply associate Lean manufacturing with waste reduction, there are a number of underlying principles that make it possible to successfully eliminate waste from the workplace. The following… …

What is Lean manufacturing?

Lean manufacturing is a system used in the manufacturing industry to help identify and eliminate waste. In practice, Lean manufacturing breaks the broad concept of waste into several sub-categories to make it easier to find and remove. Many companies have been able to save a significant amount of time, money, and other resources by using… …

What is the Lean manufacturing process?

The specific processes used by a company that is following Lean Manufacturing techniques will vary based on their business model. All Lean Manufacturing companies, however, will need to follow the same basic concepts or processes. This will allow them to identify the waste, find ways to eliminate it, and then implement those improvements. The steps… …

What are the 7 (or 8) wastes of Lean manufacturing?

Lean manufacturing is focused on waste identification and elimination in the workplace. When using this program, it is necessary to get specific in regard to what types of waste exist, so that it can be more easily eliminated. With this in mind, the Lean manufacturing system classifies seven specific types of waste, and one additional… …

How can Lean manufacturing help a company?

If you are thinking about implementing Lean manufacturing in your facility, you will want to take some time to understand how it will help the company. Most people understand that Lean manufacturing is a waste reduction and elimination program, but what does that mean on a practical level. Read on to get some good examples… …

How can I implement Lean manufacturing?

Implementing Lean manufacturing into your facility can help to identify and eliminate many types of wastes, which can have big benefits for your bottom line. Getting started off on the right foot is important for ensuring you get the best results possible. The following are some key tips for implementing a Lean manufacturing program in… …

How is Lean different from Six Sigma?

When looking for ways to improve a business, many people will look at Lean manufacturing and Six Sigma and see a lot of similarities. While it is true that they are both primarily focused on eliminating waste in the workplace. While their goals are similar, the methods that are used for achieving them is quite… …

What is Lean management?

In order to successfully implement Lean manufacturing, you need to have the leadership exercising Lean management strategies. This is when leaders push the concept of continuous improvement and waste elimination from the top down. It is not sufficient just to have one Lean manager driving the concepts of Lean manufacturing throughout the facility. Instead, every leader… …

Why is Lean manufacturing called Lean?

Lean manufacturing is a very popular strategy that helps companies to reduce waste so they can improve the bottom line of their facility. The strategy is so popular that many people never even think about the name anymore, but it is somewhat unusual. So, the question may arise about why it is called Lean Manufacturing.… …

What are Lean terms?

When working to start or expand a lean manufacturing system, you will run across a variety of different terms. If you’re not familiar with them, it can be quite confusing. While no facility uses every one of the terms listed, it is good to at least have a basic understanding of what they mean so… …

![Military Equipment [Condition Tags & Labeling]](https://www.creativesafetysupply.com/content/images/articles/military-equipment-th.jpg)

![8 Wastes of Lean [A Guide to Manufacturing Wastes]](https://www.creativesafetysupply.com/content/images/articles/8-wastes-th.jpg)

![Six Sigma Belt Levels [Hierarchy of Certification]](https://www.creativesafetysupply.com/content/images/articles/six-sigma-belt-levels-th.jpg)

![What is a Kaizen Event? [Planning and Execution]](https://www.creativesafetysupply.com/content/images/articles/kaizen-event-th.jpg)

![Balanced Scorecard [Definition + Examples]](https://www.creativesafetysupply.com/template/images/articles/balanced-scorecard-thumb.jpg)

![What is a Gemba walk? [Lean Manufacturing Definition]](https://www.creativesafetysupply.com/template/images/custom/lean-articles/articles-gemba.jpg)

![Lean Manufacturing [Techniques, Solutions & Free Guide]](https://www.creativesafetysupply.com/template/images/custom/lean-articles/articles-lean-manufacturing.jpg)

![The 5S System [Lean Manufacturing Methodology]](https://www.creativesafetysupply.com/template/images/custom/resources-page/Articles-5S.jpg)