Construction work is among the most hazardous professions in the United States, with a high number of fatalities and injuries. In 2023, construction workers experienced the most fatal work injuries compared to any other industry sector. While the overall number of fatal work injuries has declined in recent years, the construction industry still accounts for a significant portion of these deaths. Employers can play a key role in reducing or eliminating these construction-related hazards by following certain rules and regulations set by organizations like OSHA.

In this article, we will look at various safety regulations for construction established by OSHA, including fall protection, trenching safety, hazardous material handling, and other critical areas addressed by the organization’s construction standards. But before we get into that, it’s important to understand the importance of construction safety. Let’s see why construction businesses need to prioritize safety.

Why is Construction Safety Important?

Construction safety is crucial for protecting workers from injuries and fatalities, but it also offers significant business advantages. Let’s look at the business reasons for prioritizing construction safety:- Profit Loss – Accidents often impair construction workers to the point where recovery times can reach up to weeks or months. In the worst-case scenario they become permanently disabled. When this happens, aside from losing precious time from an experienced employee, the employer’s insurance premiums may skyrocket. When insurance costs go up, so does the price tag for hiring these construction companies, which may result in less job opportunities. Accidents cause monetary loss in the long run.

- Productivity Loss – As we know by now, accidents resulting from a lack of adequate safety procedures often lead to injuries. Those injured employees and any damaged equipment are incapable of getting work done for obvious reasons. Furthermore, both people and equipment used in these kinds of specialized environments are very difficult to replace, which can delay production even more.

- Workers’ Compensation and Medical Bills – If it has been determined that an accident occurred due to employer negligence regarding safety protocol, then any construction workers that were injured will most likely require compensation. These payments include lost wages, medical treatment, ongoing care costs, and even compensation for disability leave. All of these, referred to as workers comp, come from the employer’s insurance policy.

- Investigation – Every serious workplace accident will most likely be investigated by authorities to determine who is at fault. If it was due to a lack of safety, the construction company may be fined and the one in charge may even face time in jail for endangering their employees. This can be prevented if all the correct safety precautions are followed.

- Negative Publicity – Delivering finished projects on time, being honest with work, and doing a good job help a construction company’s reputation. However, accidents can quickly demolish those aspirations. If a construction company is known to not be as safe on the job as they should, project managers or business owners may not want to hire that particular construction firm.

- Worker Distrust – Unsafe environments in the construction industry often result in a lack of trust between employees and their employer. Employees put their lives on the line every day and with that they expect the employer to care about their well-being and safety. Distrust breeds discontent, leading to a divide between employers and employees that is dangerous for both parties.

There are countless reasons why construction safety is important. The above reasons are only a handful, but some of the most important. Staying informed about and adhering to construction safety standards and regulations, such as those established by OSHA, is essential to ensure worker safety, prevent accidents, reduce legal and financial risks, and foster a positive work environment.

OSHA Standards for Construction Safety

There are definitely too many construction regulations put forth by OSHA to name every single one of them here. With that being said, here are the top ten most cited regulations that OSHA doles out to worksites after a routine inspection. They are as follows:

- Fall Protection, general requirements ( 29 CFR 1926.501) : This requires employers to provide fall protection for workers at heights of 6 feet or more, and includes requirements for guardrails, safety nets, and personal fall arrest systems.

- Hazard Communication, general industry ( 29 CFR 1910.1200) : This standard requires employers to develop a hazard communication program, including labeling containers, providing Safety Data Sheets (SDSs), and conducting employee training.

- Control of Hazardous Energy (lockout/tagout), general industry ( 29 CFR 1910.147) : This regulation mandates that employers establish a program to prevent unexpected energization, start-up, or release of stored energy during servicing and maintenance of machinery and equipment. This involves using energy-isolating devices and lockout/tagout procedures to ensure employee safety.

- Ladders, construction ( 29 CFR 1926.1053) : This OSHA standard for construction safety emphasizes safety in ladder use by addressing both the condition of the ladder and its proper application.

- Respiratory Protection, general industry ( 29 CFR 1910.134) : This requires employers to establish and implement a comprehensive written respiratory protection program whenever respirators are necessary to protect employee health from airborne hazards.

- Powered Industrial Trucks, general industry ( 29 CFR 1910.178) : This OSHA regulation requires employers to ensure their employees who operate powered industrial trucks (e.g., forklifts) are trained and evaluated for competency before being authorized to operate the equipment

- Fall Protection Training, construction ( 29 CFR 1926.503) : This OSHA construction safety regulation mandates that employers provide comprehensive training to employees exposed to fall hazards. This training must enable employees to recognize fall hazards and understand the procedures for minimizing those hazards. A competent person must conduct the training, and employers must verify the training through written certification records.

- Scaffolding, construction ( 29 CFR 1926.451) : This OSHA regulation addresses the safe construction, use, and dismantling of scaffolding, including requirements for platform construction, guardrails, and access.

- Eye and Face Protection, construction ( 29 CFR 1926.102) : This OSHA standard for construction safety mandates that employers provide and ensure the use of appropriate eye and face protection for employees exposed to eye and face hazards. This includes protection from flying particles, molten metal, chemicals (liquids, gases, or vapors), and potentially harmful light radiation.

- Machine Guarding, general industry ( 29 CFR 1910.212) : This OSHA regulation requires employers to safeguard employees from hazards created by machinery. This includes protecting operators and other employees from hazards like point of operation, in-running nip points, rotating parts, and flying chips and sparks.

Although the 29 CFR Part 1926 specifically addresses construction safety, employers in construction must also be aware of and comply with relevant sections of 29 CFR Part 1910 (General Industry). This is because some hazards and safety requirements are applicable to both general industry and construction, as you can see in the above list of most cited regulations.

What are the Most Common Safety Hazards in Construction?

When working on or around construction environments, everyone needs to be aware of what are called the “fatal four.” Seems a little ominous, but that phrase refers to the four most common dangers associated with construction sites. In fact, when all four instances are combined, they account for more than half of all fatalities in the construction industry. They are the following:

Falls: This safety hazard includes falls from heights, such as roofs, ladders, or scaffolding, as well as falls on the same level due to slips, trips, and uneven surfaces.

Struck-By: This hazard involves being hit by falling objects, swinging equipment, or moving vehicles.

Caught-In/Between: This occurs when a worker is caught or crushed between moving objects, equipment, or collapsing materials.

Electrocution: This includes hazards from exposed wiring, faulty equipment, and unsafe electrical practices.

The above four are the most common reasons for fatalities occurring in construction accidents. However, there are other risks that employees encounter while on the job. For example, they could have become injured but were working alone. Without anyone around to check and see where this person was, they may die from the injuries they sustained. As a solution to that, try having workers be in pairs while performing tasks or even give them a way of contacting others in the event of an accident.

Whether it be communication regarding an accident or communication involving training on the employer’s end, being able to collaborate and solve problems as a team is essential for this kind of occupation.

What Can an Employer Do to Reduce Existing Hazards?

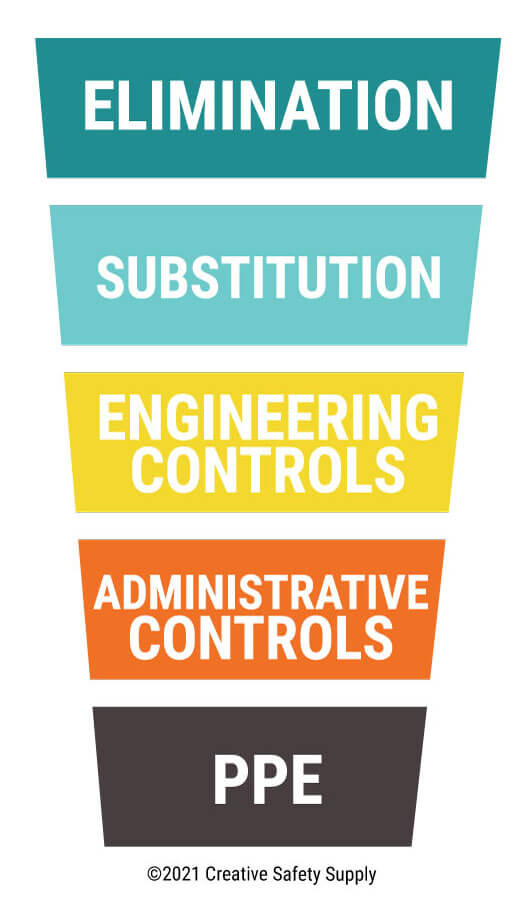

In many instances, employers in the construction industry solely use personal protective equipment (PPE) to protect their employees. However, using PPE as the primary method of hazard control is a flawed approach as per the hierarchy of controls, a fundamental principle in workplace safety that says PPE should be the last line of defense, not the first.

Understanding the hierarchy of controls is essential to ensure the effective use of PPE and reduce existing hazards in the workplace. So let’s see the hazard control options according to this approach.

Normally depicted as a triangle, it can face either right side up or upside down and includes five sequential hazard minimizing techniques. They are as follows:

- Elimination of Hazards – By far the most effective way to prevent accidents from ever occurring is by working to eliminate any and all hazards entirely.

- Reduction of Hazards – Next down the line is a reduction of the existing hazards. This should be done if the hazard cannot be eliminated or replaced all together. Consider adding more machine guards, updating old machinery to options that have more safety features, or anything else that may help get rid of unnecessary risks.

- Implementing Engineering Controls – After attempting the first two options and the hazard is still present, try using engineering controls such as modifying the existing system to provide better protection to employees.

- Implementing Administrative Controls –This takes the form of rules, operating procedures, the implementation of safety signs to alert workers. All of this should be put in place by the employer.

- Personal Protective Equipment – Last but not least comes the PPE. With all the hazardous conditions minimized in the workspace, the employer now has to choose the appropriate PPE for their employees. Now that the environment is much safer for those employees, the PPE provides protection that will likely save their lives in the event of an accident.

By following the hierarchy of hazards, the construction site should become free from the more dangerous risks. The next part that comes into play for reducing hazards and promoting site safety is reinforcing the adherence to all new protocols, procedures, and safety rules.

Conclusion

Safety in construction is essential for both the well-being of workers and the overall success of construction businesses. Therefore, employers should provide a safe work environment, which includes adhering to OSHA standards, identifying hazards, and implementing control measures like the hierarchy of controls to mitigate risks and ensure business continuity.

Similar Articles

- Safety Protocols for Construction Sites

- OSHA Facts [Updated Statistics 2019]

- Crane Safety

- OSHA Ear Protection Requirements (Standards for Hearing Safety)

- OSHA Accident Reports

- Fall Protection in the Workplace: OSHA’s Guidelines

- Understanding the OSHA 300 Log and Other Incident Paperwork

- OSHA Safety Sign Requirements [1910.145]

- Improving Workplace Electrical Safety

- OSHA’s Guidelines to Protecting Employees from Coronavirus