Valve tagging has evolved alongside industrial safety standards. Early tagging systems were simple physical markers, but modern tags now include durable plastic, engraved metal, and digital components like QR codes for digital tracking. As part of a broader pipe and valve marking system, valve tags support operational clarity, safety, and regulatory compliance.

In the U.S., valve tagging requirements are influenced by organizations like ANSI and ASME, with OSHA implicitly supporting valve identification for controlling hazardous energy. Proper valve identification also helps comply with OSHA's General Duty Clause, ensuring hazards are identified and mitigated, which prevents accidents and promotes a safe working environment.

If you're ready to start introducing valve tags into your facility, here is what you need to know.

Industry Standards For Identification of Valve Tags

Your facility can benefit from learning as much as possible about the various valve standards you are required or recommended to follow. You can add information about these standards to your valve tags so people know they must remain in compliance at all times. Some companies even put valve tags that specifically address regulatory requirements. These are some of the different valve tag identification standards in place that you should be aware of when running any type of facility:

International Organization for Standardization (ISO)

The International Organization for Standardization (ISO) is one of the largest and most influential organizations that sets standards that are adopted by many countries. The ISO 5209 offers guidelines on marking requirements on the valve body, flange, and identification plate. It offers a set of scope and terms of identification. Provisions include, but are not limited to:

Integral marking

Integrally cast, forged, or stamped marking on the body or bonnet/cover of the valve.

Marking plate

Plate fixed to the body or bonnet carrying required or mandatory markings.

Identification plate

Plate fixed to the valve with identification or other markings.

European Committee for Standardization (CEN):

CEN is the organization that creates and approves most of the standards for the European countries. These standards are sometimes adapted for other countries outside of the region as well. The EN 1349 for industrial process control valves was created for metallic valves to help ensure the safety of metallic equipment.

CSA (Formerly Canadian Standards Association)

CSA offers many optional and mandatory standards that facilities need to follow, including many for valve safety and tagging. CSA offers guidance by enlisting the manufacturer's name, model number, and pressure ratings to communicate information about a pipe within the database. Although the CSA does not have its own color-coding system, the ANSI standard can be used as a substitute.

The ANSI/ASME A13.1

While there isn't a specific, separate standard just for valve tagging in the USA, the ANSI/ASME A13.1 guidelines are typically extended to them for consistency. The standard recommends the use of a permanent, legible tag for valve and fitting identification, especially for pipes with a small outside diameter where direct pipe marking may be difficult. These tags should use the same color-coding scheme and provide an identifying label to ensure safety and efficiency in operations and emergencies.

Color Codes:

Valve tags often use the same color coding as the piping systems to ensure a consistent visual language for identifying system contents. Since most facilities adhere to the ANSI/ASME A13.1 guidelines for pipe labeling, valve tags should be color-coded in the same manner. The ANSI/ASME A13.1 color code includes six standard colors and four user-defined colors that are as follows:

Common Valve Tag Materials

Valve tags are made from the following materials for usage in different industries and conditions.

Stainless Steel

Highly durable and corrosion-resistant, stainless steel valve tags are ideal for harsh environments, chemical plants, and outdoor applications. They maintain legibility for years, even under exposure to moisture, heat, or chemicals.

Aluminum

Lightweight yet strong, aluminum valve tags are easy to engrave and suitable for moderate or low-temperature settings. Their resistance to cold makes them ideal for refrigeration systems or outdoor use in cold climates.

Brass

Brass tags combine strength and heat resistance, making them suitable for high-temperature or mechanical environments. They resist corrosion and are often chosen for compatibility with brass piping systems or equipment.

Plastic

Plastic valve tags are affordable, lightweight, and available in many colors for easy coding and customization. They work well for indoor or low-impact environments, offering flexibility for quick updates and replacements.

The best choice depends on the application's environmental conditions, as metal valve tags are ideal for harsh, hot, or corrosive settings, while plastic excels in moisture-heavy areas and offers color-coding options.

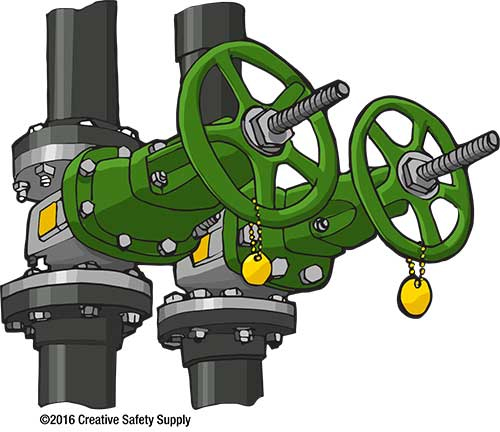

Placement

Visibility matters when it comes to placing your valve tags. The key is to make sure that the tags are placed in conspicuous and accessible positions where workers can easily and clearly see them from different angles.

- Make sure that tags don't get in the way of the valve. This may prevent certain actions, leading to complications.

- The writing should appear from the right side of the tag, which can help aid quick identification for personnel and emergency first responders.

- Place the valve tag where it's visible from different angles in the workplace. Test its location first before finalizing its position.

Valve Tag Schedules & Their Importance

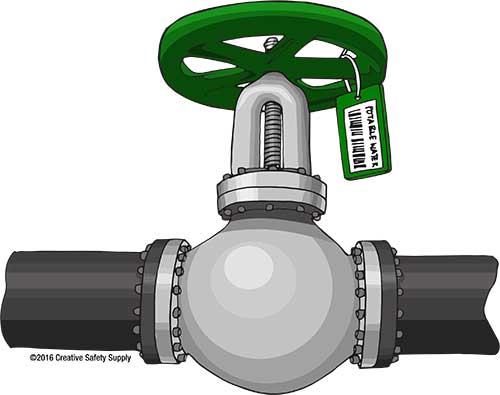

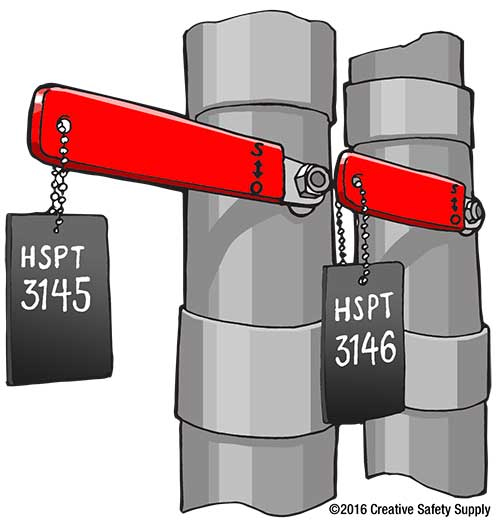

A valve tag schedule, also known as a valve chart, is a detailed list of the valves in a system that contains the location, identification number, service, and purpose of each valve in the facility. In short, it acts as a database to learn about each valve present in the facility.

When used with other safety tools, these schedules can serve as a guideline for maintenance personnel and emergency first responders to quickly identify valves and understand hazards.

Combining Valve Tags and Pipe Markers For Operational Efficiency

Using valve tags with pipe labels can help ensure safe and efficient operations. Their combined function can help workers identify the valve's function and relevant hazards before making any changes to the valve. Combining the two can aid in many functions, including:

Prevents accidents:

Identification numbers and color codes can help reduce accidental chemical releases, injuries, and equipment damage.

Increased employee morale:

Employees grow confident in their ability to assess and make quick decisions regarding pipe valves, leading to better overall performance and teamwork.

Regulatory compliance

Compliance with OSHA's hazard communication and lockout tagout requirements can prevent penalties and litigation.

Tips on Maintaining Valve Tags

Valve tags can wear or be lost, requiring a proactive inspection and replacement to maintain safety and efficiency. Here's how you can maintain and clean the valve tags:

Get Your Facility Ready With Valve Tags

Valve tags can aid in legal compliance and enhance workplace safety. By choosing the right valve tagging materials from Creative Safety Supply, following recognized standards, and maintaining an organized tagging schedule, your facility can minimize risks, prevent costly errors, and remain compliant with industry regulations.

Contact Us

Helpful Resources