Understanding confined space hazards is essential for workplaces that have these types of areas on site. Even if employees aren’t tasked with jobs that require their presence in these spaces often, they need to know how to keep themselves and others safe, as well as stay OSHA compliant. When trained properly, confined space safety efforts can minimize risks for those who are required to enter these areas.

What is a Confined Space?

Confined spaces are areas that weren't designed for regular human occupancy due to size, restricted means of entry and exit, and a hazardous atmosphere. In many cases, a confined space also has the potential to cause someone to get stuck or run into a variety of other safety and health hazards such as a lack of oxygen or a risk of asphyxiation.To get a better grasp of the vast characteristics of confined spaces, the following is a list of common places that are classified as such:

- Tanks, Vessels, and Storage Bins – These can be considered confined because there is only one way in or out during cleaning operations.

- Silos – Silos are very large, but people often fail to think about them when discussing confined spaces. There is limited room, limited exits, and the ability to become trapped or buried.

- Vaults – Whether a bank vault or a storage vault, these are often large enough to walk in and move around, but still quite cramped.

- Pits – This is another often-overlooked example. If someone falls into a pit, they may have quite a bit of room to move around. Despite this, however, they are still stuck in one area.

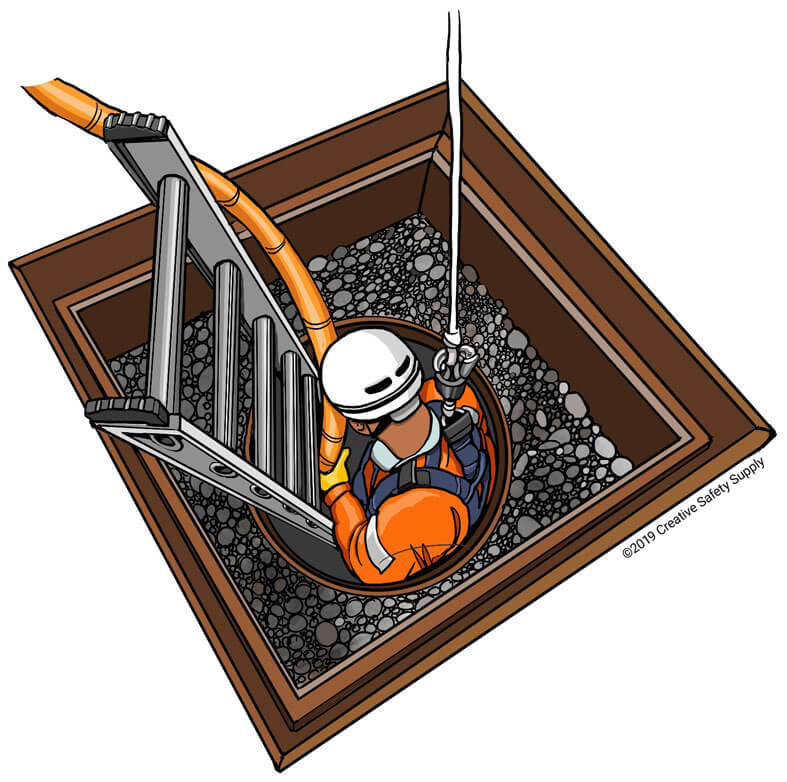

- Manholes and Tunnels – Both of these typically only have one entry/exit, are very tight spaces, and have the additional possibility of having a hazardous atmosphere.

- Ductwork – Large facilities have ductwork big enough for people to fit inside, which may be required for cleaning or other maintenance work.

- Pipelines – Pipes are very similar to ducts; except they transport liquid or gas.

Hazards of a Confined Space

Confined spaces pose significant risk due to their unique characteristics. These enclosed areas often have limited access, poor ventilation, and the potential for hazardous atmospheres. Understanding the various hazards associated with confined spaces is crucial for ensuring safety and preventing accidents.

Around 2.1 million workers enter confined spaces to perform work-related tasks every year. Out of those 2 million, there are about 100 who never return home, 60% of those deaths being employees who attempted to rescue already trapped victims.

Entering a confined area needs to be done very intentionally to avoid problems. For example, employees who need to enter large pipes should understand that their body could cut off the light and their air supply, so they need to bring an SCBA for respiratory protection and a flashlight. The following are additional examples of existing health and safety hazards within confined spaces:

Atmospheric Hazards

One of the primary concerns in confined spaces is the potential for hazardous atmospheres. These include:

- Oxygen Deficiency: Insufficient oxygen levels can lead to hypoxia, a condition where the body doesn't receive enough oxygen. This can cause several issues like dizziness, confusion, unconsciousness, and even death.

- Oxygen Enrichment: While oxygen deficiency is a common hazard, oxygen enrichment can also be dangerous. Excessive oxygen levels can increase the risk of fires and explosions.

- Toxic Gasses: Many industrial processes release toxic gasses that can accumulate in confined spaces. These gasses can cause a variety of health problems, including respiratory irritation, headaches, and even long-term health effects. Examples of toxic gasses include carbon monoxide, hydrogen sulfide, and chlorine.

- Combustible Gasses: Confined spaces can contain combustible gasses, such as methane and propane. These gasses can ignite and cause explosions if exposed to a spark or flame.

Other Hazards

In addition to atmospheric hazards, confined spaces can also pose other risks:

- Dust: Excessive dust can create a hazardous environment. It can be a fire hazard, and inhalation can cause respiratory problems.

- Temperature Extremes: Confined spaces can experience extreme temperatures. High temperatures can lead to heat exhaustion or heat stroke, while low temperatures can cause hypothermia.

- Explosion Hazards: The presence of combustible gasses and oxygen can create a dangerous environment for explosions.

- Access Restrictions: Limited access can make it difficult to rescue workers in case of an emergency.

- Ventilation Issues: Poor ventilation can contribute to the accumulation of hazardous gasses and create a suffocating environment.

Confined Space Safety Practices

Confined spaces are enclosed areas that are not designed for continuous occupancy and have limited or restricted means of entry and exit. These spaces can pose significant hazards to workers due to their unique characteristics. To ensure safety, it's important to implement effective confined space safety practices.

Controlling Confined Space Hazards

- Permit-Required Confined Space Entry (PERMIT-RCSE):

- It is essential to Implement a formal permit system to authorize entry into confined spaces. Permits should only be issued after a thorough assessment of hazards and the necessary precautions have been taken.

- You may also conduct a comprehensive hazard assessment before each entry, identifying potential hazards such as toxic gasses, oxygen deficiency, flammable atmospheres, or mechanical hazards.

- You need to ensure adequate ventilation to remove hazardous gasses and maintain sufficient oxygen levels.

- You may use continuous monitoring equipment to monitor atmospheric conditions throughout the entry.

- Have a well-defined emergency response plan in place to address potential incidents.

- Note that you only allow trained and authorized personnel to enter confined spaces.

- Make it a rule that an attendant is required to remain outside the confined space to monitor the entry and provide assistance if necessary.

- Ensure that appropriate emergency rescue equipment, such as harnesses, lifelines, and retrieval systems, is readily available.

- Maintain effective communication between the entrant and the attendant using appropriate communication devices.

- You would need to have clear exit paths that are unobstructed and clearly marked.

- Establish emergency exit procedures to be followed in case of an emergency.

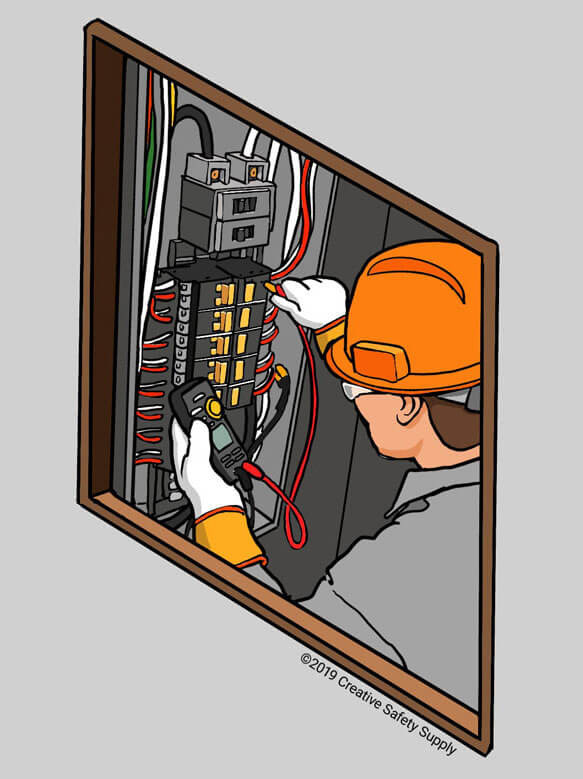

- Personal protective equipment is extremely important when working in a confined space. Just like under normal working conditions, the specific types of PPE required will vary from location to location. Hard hats, protective gloves, shock-resistant clothing, facemasks, eye goggles, hearing protection, and more may be required to keep employees safe.

- Employers are legally required to provide the necessary PPE for employees working in confined spaces. All PPE should be kept in an area near the entrance to a confined space, and signs should be put up letting employees know that they cannot enter without first putting on the required PPE.

- Confined Space Safety Signs:

- Post clear and conspicuous warning signs at all entrances to confined spaces, indicating potential hazards and the requirement for a permit.

- Install emergency exit signs to guide workers to safe exits in case of an emergency.

- Provide regular training to all employees who may enter confined spaces, covering topics such as hazard identification, entry procedures, emergency response, and the use of PPE.

- Conduct competency assessments to verify that employees have the necessary skills and knowledge to perform their duties safely.

- The potential exits of a confined space should be clearly marked so the employees can see them. These exits should be marked with something that can be seen easily, even if the area became dark or smoky. Having the ability to exit a confined space quickly is one of the most important ways to stay safe.

- Anyone entering a confined space should have a partner who remains outside of the confined space, but in constant visual and auditory contact. Should something go wrong, the person outside of the confined space can quickly call for help. It’s important to note that the person outside the confined space should not enter to provide assistance unless there is someone else there with them who can stay on the outside to seek additional assistance.

Oxygen Levels in Confined Spaces

Oxygen levels in confined spaces can fluctuate significantly, posing a serious health hazard to workers. Oxygen deficiency, also known as hypoxia, occurs when oxygen levels fall below the normal atmospheric concentration of 19.5%. This can lead to a range of symptoms, including dizziness, headache, fatigue, nausea, and even loss of consciousness. In extreme cases, oxygen deficiency can be fatal.

It's essential to monitor oxygen levels in confined spaces before, during, and after entry. This can be done using portable oxygen meters or continuous monitoring systems. If oxygen levels are found to be below the safe limit, appropriate measures must be taken to improve ventilation or restrict entry until the oxygen levels return to normal.

OSHA Standard for Confined Spaces

The Occupational Safety and Health Administration (OSHA) has established specific standards for confined spaces to protect workers from the hazards associated with these environments. These standards outline the requirements for employers to identify, evaluate, and control confined space hazards.

Key elements of the OSHA standard for confined spaces include:

Permit-Required Confined Space Entry (PERMIT-RCSE): Employers must implement a permit system for confined spaces that require special precautions. Permits should only be issued after a comprehensive hazard assessment and the necessary precautions have been taken. This rule is 29 CFR1910.146, and is very important for employers to be aware of before having anyone work in a confined area.

OSHA defines a confined space as one that has limited entry/exit, is large enough for a person to enter and perform work but isn't designed for continuous occupancy. A permit-required confined space has all of the characteristics of a confined space, plus an additional hazard such as:

- A hazardous atmosphere

- A material that can engulf someone

- Unguarded machinery or wires

- Floors and walls that taper in a way that could trap a person

- When in doubt, it is best to contact OSHA directly to have them help determine when a permit is required and when it’s not. Depending on the situation, they can either evaluate a confined space over the phone or send out an inspector to help look at the area and decide.

- Another great option is to use the OSHA Confined Spaces Advisor. This is an online tool that goes through several questions. Based on the answers to these questions, OSHA will make recommendations on whether or not the area is classified as a permit space.

- Identifying and Controlling Hazard: Employers must conduct a thorough hazard assessment to identify potential hazards such as toxic gasses, oxygen deficiency, flammable atmospheres, or mechanical hazards.

- Ventilation: Employers must ensure adequate ventilation to maintain safe oxygen levels and remove hazardous gasses.

- Personal Protective Equipment (PPE): Personal protective equipment is extremely important when working in a confined space. Just like under normal working conditions, the specific types of PPE required will vary from location to location. Hard hats, protective gloves, shock-resistant clothing, facemasks, eye goggles, hearing protection, and more may be required to keep employees safe.

Employers are legally required to provide the necessary PPE for employees working in confined spaces. All PPE should be kept in an area near the entrance to a confined space, and signs should be put up letting employees know that they cannot enter without first putting on the required PPE. - Training: As with just about all workplace safety efforts, being safe in a confined area starts with proper training. All employees who work in or around confined areas must go through a formal training program provided by their employer. In many cases, these training programs need to be approved by OSHA in order to get the necessary permits. Regularly taking safety classes and taking opportunities for refresher training are also excellent.

Even in areas that aren't legally defined as confined spaces providing training to anyone who works in smaller environments due to the elevated risks is still recommended. Most companies that provide this type of training do it as part of their new employee orientation process, and then also invite seasoned employees to take the training if they are changing jobs or need a refresher. - Emergency Response Plan: Employers must have a well-developed emergency response plan in place to address potential incidents.

Other Equipment for Confined Spaces

- An Air Supply - While it does not apply to every situation, in confined spaces, oxygen levels can be depleted quickly.

- Light Source - Having a personal light source like a flashlight is very important. If the lights become damaged or otherwise go out in a confined space, having the ability to illuminate the area can help ensure the employee's safety.

Investing in the right type of equipment for working in an enclosed area is critical for the safety and health of employees, as well as for remaining in compliance with OSHA regulations.

Taking Confined Space Safety Seriously

One of the biggest problems with confined space safety programs is that many employees and even employers don't take them seriously. While everyone knows there is a potential for danger in a confined space, people become overconfident that an accident won't happen to them. Employers and employees need to realize that the safety and health hazards listed above can happen to anyone at any time.Similar Articles

- Arc Flash and Electrical Safety

- Arc Flash PPE

- Hierarchy of Controls [Hazard Exposure + Prevention]

- Hazardous Waste Disposal

- Mine Safety & Health [Expert Advice]

- 10 Essential Steps for Electrical Safety

- Fire Prevention in the Workplace [OSHA 1910.39]

- Anhydrous Ammonia – Safety & Labeling

- Typical Lockout Tagout Procedures

- Job Safety Analysis