Resources

PPE Articles

Lean Safety | Understanding the Lean 6S Methodology

Implementing lean safety can result in safer and more efficient working conditions that minimize errors and require fewer corrective measures. …

Addressing Biohazard Safety in the Workplace

Biohazards consist of bacteria, virus, and fungi pathogens, as well as parasites. Remembering to provide the correct equipment, training, and visual communication is essential. …

How to Practice Social Distancing in Manufacturing Facilities

Social distancing and other protective measures have become a staple in occupational health and safety efforts due to COVID-19. New Social distancing guidelines from OSHA. …

OSHA Respiratory Protection Standard (29 CFR 1910.134)

Respiratory protection is essential where toxic substances are present, without PPE employees may suffer from long lasting injury or illness and even death.got …

An Introduction to Industrial Hygiene

OSHA claims industrial hygiene is the science of anticipating, recognizing, evaluating, and controlling workplace conditions that may cause workers' injury or illness. …

Fall Protection in the Workplace: OSHA’s Guidelines

Falls are among the leading causes of work-related injuries. Learn about the fall arrest equipment you need and best practices for a fall protection program in your workplace. …

OSHA's Guidelines to Protecting Employees from Coronavirus

Learn which OSHA standards apply to preventing exposure to illness in the workplace, how to determine level of risk, and which controls to implement to protect your workers. …

Fire Safety in the Workplace

Fire safety is essential in every workplace. These are the principles that will help your facility prepare for fires and prevent them from occurring in the first place. …

Mine Safety & Health [Expert Advice]

Miners face many hazards that put their safety at risk. By adhering to MSHA standards and providing training and appropriate equipment, employers can enhance mining safety. …

Emergency Spill Cleanup & Containment

When a spill occurs at work, safety relies on a fast response. These are the steps to take and best practices for spill cleanup. …

NFPA 70E [Workplace Electrical Safety]

NFPA 70E was created to help prevent injuries to workers in energized environments. If you’re working with live energy, you need to know this safety standard to stay OSHA compliant. …

Calculating Overall Equipment Effectiveness (OEE)

Are your lean and 5S efforts making a difference? Crunch the numbers on OEE to find out! …

Workplace Lifting Safety

Lifting heavy items is one of the leading causes of injury in the workplace. Save time and money by learning how to prevent lifting injuries. …

Hard Hat Classes [OSHA & ANSI Standards]

Each hard hat class is designed specifically to help provide protection against certain types of hazards. Learn about hard hat classes to ensure the right hats are used to keep everyone safe. …

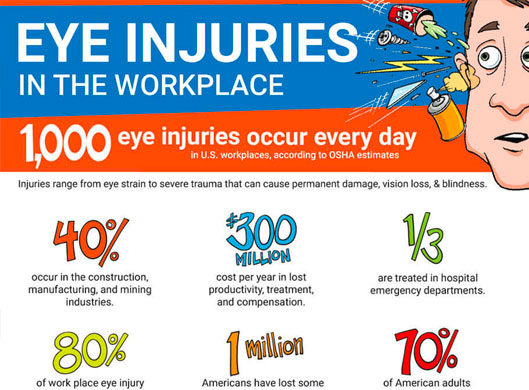

ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]

ANSI Z87.1 focuses on safety glasses and helps employers and employees make decisions that can help protect people’s eyes and face from a variety of threats. …

5 Lean Manufacturing Tools that Work

These five lean manufacturing tools are essential for making your lean journey a success. …

Confined Space Hazards

When is it safe to work in a confined space? Get the details in this article. …

Arc Flash PPE

Make sure everyone knows what protective equipment they need to work near this serious hazard. …

PPE: Personal Protective Equipment [Safety Standards]

Get an overview of common PPE requirements for the workplace including breathing protection, eye protection, and more. …

PPE Questions and Answers

What are the "Dos" and "Don'ts" of PPE?

Personal Protective Equipment (PPE) is worn to minimize exposure to potential dangers, keeping employees protected from any hazards which may be present in the workplace. Ensuring that the correct PPE is provided is a necessity to ensure its effectiveness. In this article, we discuss some of the key PPE dos and don'ts alongside some examples… …

What Types of Hearing Protectors are Available?

When people think of workplace safety, they often overlook one of the most common hazards that exist in most places. Sound. Machines, large fans, vehicles, and other things all contribute to producing noises that can cause damage to people’s hearing. Whether that is from sudden very loud noises or constant lower-level noises, hearing protection is… …

Is Personal Protective Equipment (PPE) A Hazard Control Method?

When most people think about how to stay safe in the workplace, they picture things like hard hats, fire-resistant gear, respirators, and other similar things. These are all examples of personal protective equipment (PPE). While there is no doubt that PPE is an important part of an overall safety effort, it should not be the… …

What Does PFAS (Personal Fall Arrest System) Stand For?

There are many times when a worker needs to climb a ladder, get up on scaffolding, or otherwise work high up above the ground. While this is often necessary, it is also very dangerous. When someone makes a slight slip, they could fall causing serious injuries or even death to themselves or anyone who happens… …

What is a FIT Test (for Respirators)?

Water is one of the most used substances in many facilities. It is used for things like drinking, cleaning, cooling, fire suppression, and much more. It is also one of the most common ingredients used in making different foods. All this means that most facilities will have one or more different water pipes that travel… …

When is high visibility clothing needed?

Hi-vis personal protective equipment is worn by workers in low-light environments or poor visibility conditions. Also known as high-visibility safety apparel (HVSA), it encompasses a range from clothing like neon yellow safety jackets, bright orange vests, lime-colored pants with reflective stripes, and even fluorescent rain gear. The Federal Highway Worker Visibility Rule Anyone working on or near… …

What is in a PPE kit?

A PPE kit, or personal protection equipment kit, is a set of PPE items that are kept together for use when needed. There can be many different types of PPE kits, each designed for a specific purpose. Having all the relevant PPE together in one kit will make it easier to ensure employees who need… …

What does SCBA stand for?

SCBA stands for self-contained breathing apparatus, sometimes called industrial breathing sets. Typically used by firefighters and in industrial workplaces, SBCAs are a type of respirator used when the atmosphere is immediately dangerous to life or health. An SCBA provides breathable air where oxygen deficiency, smoke, dangerous gases, or other airborne contaminants present. SCBAs were also… …

What does APR stand for?

Air-purifying respirators, commonly known an APRs come in handy when working in hazardous environments. They can be seen in situations where healthcare professionals are dealing with infectious diseases, first responders may use them during natural disasters, and more commonly used in occupations that entail working in conditions with high volumes of particulates like dust, vapors,… …

What is HVSA?

HVSA stands for High Visibility Safety Apparel. HVSA is sometimes called ‘hi-viz’ clothing for short. It is a type of clothing that is designed specially to be easy to see in any type of light. The clothing must be highly luminescent or a color that is easily discernible from the background that it will be… …

What does the Z87 on safety glasses mean?

When looking at safety glasses you may have noticed that they say Z87 on them and wondered what exactly that meant. This is an indication that the glasses are made to the specifications required by the ANSI Z87 set of standards. ANSI is the American National Standards Institute, which is a non-profit organization that is… …

What is the proper way to dispose of PPE?

Personal protection equipment, or PPE, is an important part of the overall safety program of any facility. There are many different types of PPE out there ranging from gloves to hardhats to full-body hazmat suits. In a lot of cases, PPE can be reused multiple times without any issues. In other situations, however, it will… …

When should ear protection be worn?

When working in loud environments people can become desensitized to the constant sound that is surrounding them. While the noise may not cause physical pain, it is often still causing serious damage to the hearing. In addition, constant exposure to loud noise has been linked to headaches, anxiety, and other health concerns. Because of this,… …

What PPE is used for working over dangerous equipment and machinery?

There are many jobs that require people to work at heights. In some of them, the jobs will need to be done directly over some type of hazard such as dangerous equipment or machinery. This is common in construction sites but can also happen in manufacturing facilities and other locations. Whenever someone has to work… …

When is hearing protection required?

Keeping employees safe is a top priority for any good company. While some types of workplace safety are obvious, such as chemical safety or slip and fall prevention, others aren’t so easy to spot. One example of a workplace risk that is often overlooked is threats to people’s hearing. Many factories and other environments can… …

What is NRR?

NRR is an acronym that stands for Noise Reduction Rating. Of all the hazards in the workplace, one of the most frequently overlooked is the dangers associated with loud noises. People who work is loud environments are at risk of hearing loss, headaches, increased anxiety, and many other problems. Since it is not possible to… …

How often should hard hats be inspected?

Hard hats are one of the most common types of personal protection equipment used in the workplace. These durable hats provide a significant protection against falling objects, bumps, and other hazards. While they are certainly made to last, they don’t last forever, which is why it is important to have them inspected regularly. Inspect After an… …

How do you clean lead contaminated clothes?

Through the course of day to day work, clothes get dirty. For most people, this just means they have to toss them in the washing machine and they are ready to go. When clothes are contaminated with potentially dangerous materials, such as lead, however, it requires specialized action. As an employer, it is important to… …

What is PPE?

Personal protective equipment (PPE) is an umbrella term for any safety garment or accessory worn by workers. It includes rubber gloves that don’t absorb chemicals, arc-rated gloves that won’t catch on fire, body harnesses that will safely suspend a falling worker, hi-vis safety vests that keep construction site workers visible to traffic, and everything in… …

How does a job hazard analysis work for PPE?

Performing a hazard assessment, also referred to as the job hazard analysis, is crucial to understand the hazards in the workplace, the severity of the hazards, and which steps in the hierarchy of hazards will be most effective. This should be completed by a few people, optimally including the facility manager and safety manager. Common… …

What are different types of hand protection?

Unlike hard hats, hearing protection, and eyewear, safety gloves are one of the few items of PPE not regulated by OSHA standards. OSHA however, does specify that employers should evaluate the conditions and hazards at hand and appropriately select safety gloves relative to the task performed and the present risk. Hands can be exposed to harmful… …

Who regulates PPE?

Personal protective equipment is crucial in keeping workers safe while on the clock and works to minimize exposure to hazards that could result in injury, illness, or even death. OSHA has set and enforces regulations regarding personal protective equipment to most workers in the United States. Many of OSHA’s requirements are aligned with the standards… …

What is hearing protection?

Providing workers with proper hearing protection is crucial to prevent irreversible hearing loss. The two types of hearing risks associated with loud noises are sudden bursts, like explosions or gunshots, and prolonged noise, common in most manufacturing facilities. Hearing loss and hearing damage is permanent and can negatively affect someone for the rest of their… …

What PPE is commonly used in construction sites?

When it comes to PPE for construction workers, the first things that come to mind are a hard hat, a safety vest, and work boots, but construction sites pose hazards that require more protection and personal equipment. Working from heights, falling objects, heavy machinery, traffic, chemicals and so much more are common hazards construction workers… …

What PPE is recommended for chemical hazards?

Laboratories are not the only workspaces that have to deal with risks associated with chemicals, other industries handling hazardous chemicals including agriculture, manufacturing, construction, transportation, and more. Some of the effects of workers coming in contact with chemicals can be temporary or have lifelong consequences. From severe chemical burns to corrosion of the skin and skin… …

What situations require PPE?

It is crucial for employees to understand when and where PPE should be worn. An employer or safety manager will first need to conduct a hazard risk assessment. This assessment consists of a thorough walk through the facility to identify all present hazards and areas that have a risk of becoming a hazard. Once this… …

What type of training is there for PPE?

Personal protective equipment does not protect the worker if it is not being used or being used incorrectly. OSHA requires employers to train each employee who will be using PPE, both existing and new hires, on the equipment in the workplace. Training is required to include: When PPE is necessary: Employees need to know and… …

What PPE can protect a worker from electrocution?

An important part of completing a hazard assessment of a facility is to understand the electrical risks. Electrical hazards pose the risk of arc flash causing electrocution, severe burns, permanent eyesight, and hearing damage, and can even be fatal in some cases. Things to look for during the assessment include outlets too close to conductors,… …

What hazards do PPE protect from?

Some hazards are easily spotted, and some hazards can seem hidden. It is important for safety or facility managers to carefully inspect the facility to identify hazards in the workplaces and areas where potential hazards could occur and purchase properly fitting and appropriate PPE. Personal protective equipment is designed to protect employees from all types of… …

How should PPE be stored?

While some workplaces will have PPE that is required on a daily basis or worn at all times, other personal protective equipment should be safely stored. The storage of personal protective equipment is almost as important has having it on hand, and an obligation set forth by OSHA, specifically requiring that PPE must be “maintained… …

What are PPE requirements?

Although PPE is considered the last line of defense, it is essential to understand OSHA’s requirements to not only stay compliant but keep your workers safe when elimination, substitution, engineering controls, and administrative controls do not entirely eradicate the hazard. Under OSHA law, employers are required to provide the properly fitting PPE that corresponds with… …

Can PPE be shared, reused, or altered?

In many instances PPE is assigned to specific individual, and it is important to train workers on different types of personal protective equipment and what that means for sharing or reusing them. When employers purchase items specific to the employer (such as proper fitting boots), they should be assigned to that worker and not shared.… …

Why is PPE considered the last resort?

PPE is often called the last line of defense because of its place on the hierarchy of hazards. When an employer or safety manager needs to address a dangerous hazard in the workplace, they should go through what is called the hierarchy of hazards to address it. The hierarchy is as follows: Starting at the top… …

Who supplies PPE at work?

Employers, under OSHA law have the responsibility to provide personal protective equipment at no cost to the worker. An employer or safety manager will need to conduct a hazard assessment of their workplace to identify all physical and health hazards present. Once it is known what PPE will be needed in the workplace, it is important… …

What are different types of PPE?

PPE can be categorized by the part of the body it protects, the type of hazard it protects from, and the type of garment or accessory. Designed to protect from head to toe, different body protection equipment can include: Skin protection: This is any type of barrier between the hazard and the worker’s skin. Common… …

What does PPE stand for?

PPE is the commonly used acronym for personal protective equipment and refers to any garments or equipment designed to be worn and protect employees from occupational hazards including physical, chemical, biological, electrical, mechanical, and radiological hazards. All types of workplaces can pose a number of risks for injury: fire hazards, sharp blades, forklifts and heavy… …

![Mine Safety & Health [Expert Advice]](https://www.creativesafetysupply.com/content/images/articles/mining-safety-th.jpg)

![NFPA 70E [Workplace Electrical Safety]](https://www.creativesafetysupply.com/content/images/articles/nfpa-70e-th.jpg)

![Hard Hat Classes [OSHA & ANSI Standards]](https://www.creativesafetysupply.com/template/images/articles/hardhat-classes-thumb.jpg)

![ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-safety-glasses.jpg)

![PPE: Personal Protective Equipment [Safety Standards]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ppe.jpg)