Fall Protection in the Workplace: OSHA’s Guidelines

Falls are one of the biggest causes of injuries and deaths in the workplace, especially in certain industries such as construction, the trades, mining, and electrical utility repair. A fall from any distance, even a short one, can result in long-term debilitating or fatal injuries. Employers are responsible to asses fall risks and implement measures to protect workers from falls.

Organizations like OSHA provide comprehensive guidelines for fall protection in workplaces to prevent injuries and fatalities from falls. These guidelines outline when and how fall protection is required, and the types of systems that must be used. This article will explore key aspects of OSHA's fall protection guidelines, including requirements for different work environments and situations.

OSHA Guidelines for Fall Protection

OSHA requires employers to prevent employee falls in the workplace by:

- Providing working conditions that are free from known dangers.

- Keeping work areas clean and sanitary so workers can see where they are going and won’t suffer from trips that may lead to a serious fall.

- Guarding any hole in the floor by erecting a railing around it and providing a floor hole cover.

- Erecting a toe board and guardrail around any floor, platform, or runway that is open-sided and 4 feet or higher off the ground (or 4 feet from the next level).

- Providing fall protection equipment such as a safety harness, personal fall arrest system, safety nets, and railings. The specific height at which fall protection is required varies by industry. For the general industry, fall protection is needed at 4 feet. In construction, it's required at 6 feet. Shipyards require fall protection at 5 feet, and longshoring operations require it at 8 feet.

While a "one-size-fits-all" approach is not recommended, OSHA's general guidelines for fall protection, including guardrails, safety nets, and personal fall arrest systems, are applicable across all workplaces.

Protecting Workers From Falls

Protecting workers from falls involves creating awareness about potential hazards and providing them with the proper fall protection equipment, along with proper training on their use to effectively prevent falls from elevated work surfaces. Let’s see how employers can create awareness and what fall arrest equipment they should provide to employees.

Signs and Barriers

Employers should utilize signs and barriers to clearly mark potential fall hazards and restrict access to dangerous areas. For instance, “Warning: Fall Hazard” signs and labels, as well as printed floor tape with hazard warning, can be installed to create awareness.

Fall Protection Equipment

Employers should provide the following fall protection equipment:

Guardrails: Guardrail systems should be installed along the edges of elevated surfaces to prevent workers from falling.

Safety Nets: Safety nets can be installed beneath work areas to catch workers who may fall.

Ladder Safety: Proper ladder safety practices and equipment, such as using ladders with proper stability and ensuring proper foot placement, should be emphasized.

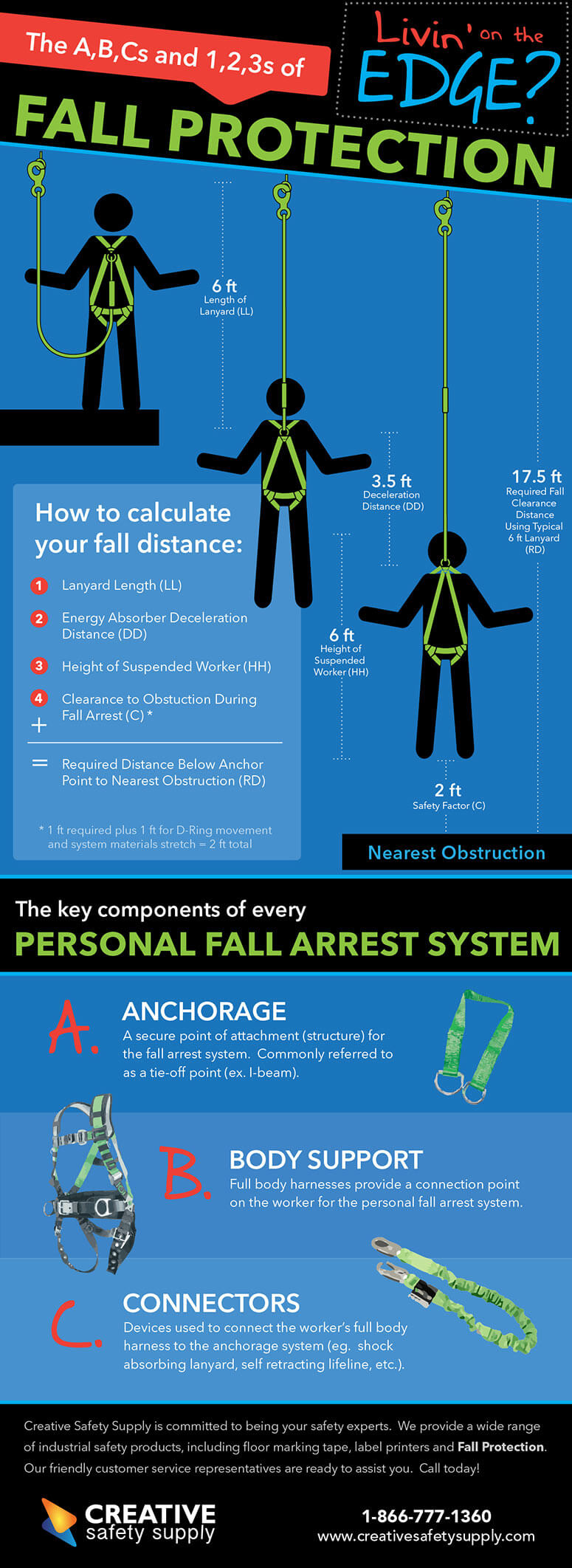

Personal Fall Arrest Systems (PFAS): PFAS, including safety harnesses, lanyards, and anchor points, should be used when other fall protection methods are not feasible.

OSHA requires a personal fall arrest system for workers who are exposed to vertical drops of six feet or more while they perform their duties. While OSHA’s standard 1926.502 covers the criteria for these fall protection systems in construction, this criteria may be also used for any industry; a PFAS is required no matter the type of task, whether the worker is in painting, mining, roofing, or electrical utility repair.

Regardless of the industry, it’s important for every worker who needs a PFAS to understand the major components of personal fall arrest systems, which are easily remembered as the ABCs, as represented in the image below:

Reducing Falls in the Workplace

Trips, slips, and falls are among the leading causes of work-related injuries in a variety of industries each year. Falls are also the leading cause of death in construction—and it is entirely preventable. Six feet may seem deceptively short for a fall, but even a short distance can result in serious or life-threatening injuries.

To help employers reduce falls in the workplace, OSHA, the National Occupational Research Agenda (NORA), and the National Institute for Occupational Research and Health (NIOSH) has come together to provide education on preventing falls, as well as enforcement on standards. You can find fact sheets on this information from OSHA, as well as an in-depth explanation of the three main steps that have been established to reduce falls: plan, provide, and train.

First, preventing falls should be an aspect to the planning of any project or job. If the task requires workers to be at heights at any time, whether it’s from ladders, scaffolding, or platforms, you need to determine what equipment may be needed ahead of time to keep people safe. Then, this fall protection gear must be provided. If the job requires personal fall arrest systems, each worker should have their own individual PFAS.

The last step is often considered to be the most important: training workers on how to use their equipment, when to use it, and how to do so properly so they aren’t injured by the equipment if they do fall. The time and money you invest in fall arrest equipment won’t matter if the equipment is not used correctly. All workers should understand the setup and use of PFAS, ladders, and other equipment, and how to properly select anchors. There are training courses available to educate employees on workplace fall hazards.

Create a Fall Protection Program

Falls are an unfortunately common cause of work-related injuries and deaths each year. By becoming familiar with safety standards, planning ahead of time, communicating about hazards, and ensuring that workers are using correct equipment, it is possible to reduce the likelihood of these incidents occurring in your workplace. You can develop and implement a comprehensive fall protection program so employees stay safe.

Similar Articles

- OSHA’s Guidelines to Protecting Employees from Coronavirus

- Job Hazard Analysis: Addressing Coronavirus Risk in Your Workplace

- Safety Colors (OSHA Guidelines and Color Codes)

- OSHA Respiratory Protection Standard (29 CFR 1910.134)

- OSHA Facts

- Improving Workplace Electrical Safety

- Fire Safety in the Workplace

- OSHA Ear Protection Requirements (Standards for Hearing Safety)

- Fire Prevention in the Workplace [OSHA 1910.39]

- OSHA Construction Safety