- What Is Fire Safety Policy?

- Fire Safety Regulations and Standards

- What is the golden rule of fire safety?

- Fire Hazards in the Workplace

- Identification of Materials and Ignition Sources

- Fire Safety Equipment

- PPE for Fire Safety

- Requirements for a Fire Emergency Plan

- Fire safety in the workplace examples

- Employee Training for Fire Safety

The National Fire Protection Association (NFPA) estimates that there are an average of 37,000 fires on manufacturing and industrial properties in the United States every year. Of these, the leading causes are cooking equipment, heating equipment, and electrical distribution/lighting equipment. When a fire breaks out, the consequences are twofold: there may be serious or fatal injuries to workers and extensive property damage. Those 37,000 fires inflict $1 billion in direct property damage.

Fire safety is incredibly important for every workplace no matter the industry, since it can happen anywhere at any time. Each facility should adhere to established fire codes, perform a thorough assessment of present fire hazards, have an extensive understanding of fire suppression equipment, and have a comprehensive emergency plan in place. Through training and preparation, you can help reduce the risk of a fire breaking out in your facility, and ensure that workers know what to do if one does occur.

What Is Fire Safety Policy?

A fire safety policy is a formal document outlining an organization's comprehensive plan to prevent fires, mitigate fire risk, and ensure a safe and coordinated response in the event of a fire emergency. This policy should encompass proactive measures like fire hazard identification and control, proper use and maintenance of fire suppression equipment, and regular fire safety training for employees.

The policy should also clearly define evacuation procedures, designate assembly points, and establish communication protocols for emergencies. By establishing a clear and well-defined fire safety policy, workplaces can empower employees and ensure everyone understands their roles and responsibilities in maintaining a safe environment.

Fire Safety Regulations and Standards

In the United States, there are three main organizations involved in fire safety regulations. These are the IFC (International Fire Code), OSHA, and NFPA.

The NFPA is the leading resource for fire hazards and safety. There are several NFPA codes regarding the workplace that are particularly important:

- NFPA 30: Flammable Liquids Code, which focuses on the safe storage of flammable liquids. Safety labels included with these liquids should list their name, flammable warning, flash point, and fire point.

- NFPA 70: National Electrical Code (NEC). This code is essential for electrical professionals, as it establishes procedures for the safe installation of electrical wiring equipment.

- NFPA 70E: Standard for Electrical Safety in the Workplace. A cousin to the NEC, this code applies to every business. It specifically focuses on three kinds of energy hazards: arc flash, electrocution, and arc blast. These hazards often cause fires.

- NFPA 72: National Fire Alarm and Signaling Code. This provides standards on fire detection and emergency communications and also covers mass notification systems for public threats such as nuclear, biological, and chemical emergencies.

- NFPA 99: Fire Safety in Healthcare Facilities, a specialized code that was adopted to address the unique environment and hazards of healthcare. In 2012, NFPA 99 became a code instead of a standard and adopted a risk-based approach.

- NFPA 704: Standard System for the Identification of the Hazards of Materials for Emergency Response, which provides a consistent labeling system for communicating hazardous materials to first responders. This code is well known for standardizing the fire diamond, which is divided into four color-coded sections and covers flammability, instability, health hazards, and special precautions.

Established by the International Code Council, the International Fire Code (IFC) is a document recognized around the world that standardizes fire safety and establishes requirements for fire protection systems, as well as fire prevention plans. It is currently used in 40 states and was created with the intention of worldwide application.

One of OSHA's primary areas of focus is fire prevention in the workplace. OSHA's standard 1910.39, “Fire Prevention Plans,” establishes requirements that help employers reduce the risk of fire and ensure that employees will be safe if a fire does occur. The standard covers requirements for a prevention plan, emergency exits, employee training, fire suppression options, and the identification of flammable or combustible materials and ignition sources. If your workplace has ten or more employees, you are required to have a fire prevention plan.

What is the golden rule of fire safety?

In fire safety, the paramount principle is prevention. This proactive approach emphasizes taking steps to minimize the risk of a fire from starting in the first place. This can involve a multitude of measures, such as maintaining electrical systems, eliminating flammable hazards, and implementing safe work practices. By prioritizing preventative efforts, workplaces can significantly reduce the likelihood of fires and safeguard both employees and property.

Fire Hazards in the Workplace

The first step to fire safety is assessing the existence of fire hazards within your workplace. In most facilities, there are three main types of hazards to evaluate: electrical hazards, combustible materials, and flammable materials.

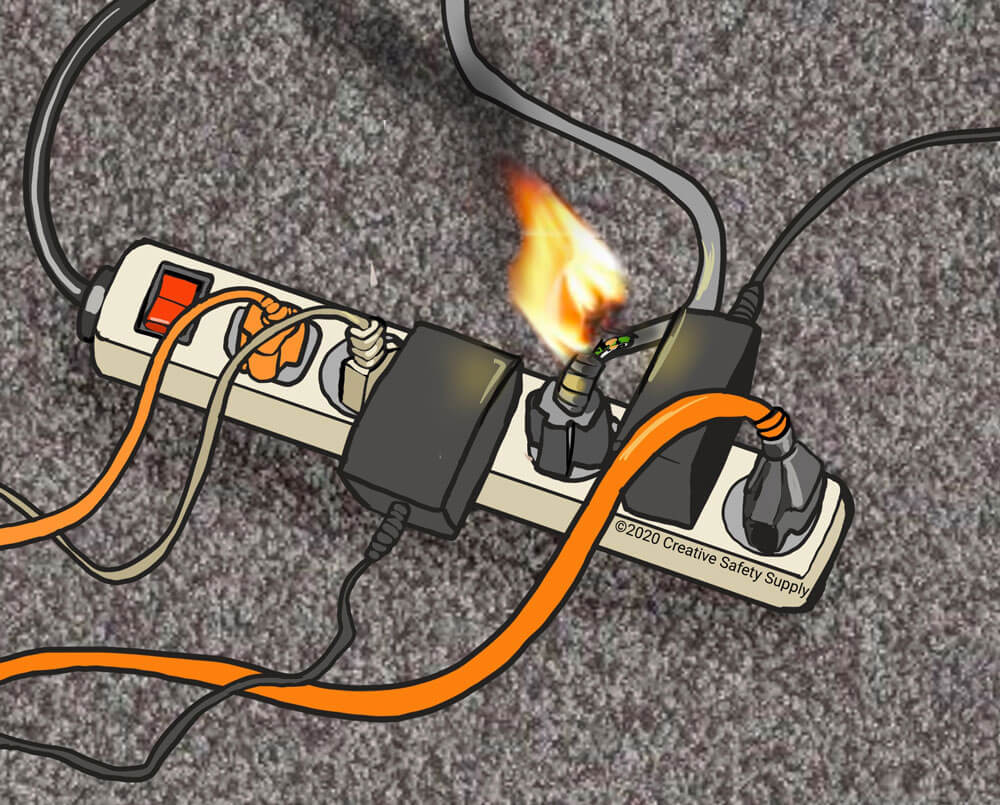

Between 2011 and 2015, lighting and electrical distribution equipment were the leading cause of structure fires on industrial properties. Electrical issues, such as damaged extension cords, blocked electrical panels and heaters, and overloaded circuits often lead to fires. Fires are also commonly caused by electrical events such as arc flashes. Maintenance of power cords and other electrical equipment should be conducted regularly.

Workplace fires are also commonly caused by improper storage of flammable material or a buildup of combustible dust. Many facilities handle flammable liquids such as solvents and paints, or there is a risk of combustible dust from coal, metals, and food products such as grain. Flammable and combustible materials both burn, just at different flash points; the difference between being “flammable” and being “combustible” is that flammable materials have low flash points (low temperatures at which surface vapors will ignite), and combustible materials have high flash point. Both are dangerous and should be properly handled and stored.

Dust explosions in particular are a dangerous yet often overlooked fire hazard. There must be five elements for a dust explosion to occur: the existence of dust, dispersion of dust, oxygen in the air, confinement, and an ignition source. These are known as the “Dust Explosion Pentagon.” Combustible dust hazards exist in a variety of industries and are deadly because an initial explosion commonly causes additional dust to be dispersed, which leads to a secondary, more destructive explosion. Fatal injuries and extensive property damage often occur during these secondary explosions. OSHA recommends a comprehensive hazard assessment of all materials, operations, spaces, and potential ignition sources within a facility to reduce the risk of these dangerous events.

Identification of Materials and Ignition Sources

OSHA 1910.39 requires that one section of each facility’s fire prevention plan identifies flammable or combustible materials within the facility, as well as potential ignition sources. Materials are classified by risk and are sorted according to these fire classifications:

- Class A Materials, materials such as wood, cloth, and paper, which won’t ignite on their own but will continue to burn once exposed to a heat source.

- Class B, all liquid, grease, and gas materials that burn when exposed to ignition sources.

- Class C, electrical materials and equipment. These materials cause fires very quickly and present a serious risk of arc flash.

- Class D, any materials that are volatile and able to quickly ignite, such as magnesium, potassium, and sodium.

Examples of ignition sources include:

- Open flames such as gas ovens, lighters in smoking areas, and welding torches.

- Sparks from wood or metal saws and other types of equipment.

- Heat sources sch as combustion engines, space heaters, ovens, and machines that produce heat during operation.

- Chemical ignition from chemicals that combust under normal working temperatures.

Safety data sheets are critical to fire safety. SDSs, which are provided by the manufacturer, distributor, or importer of a chemical, will describe safe storage and handling methods, as well as any special fire prevention precautions. They also provide an identification of hazards and describe measures for firefighting should the chemical cause a fire. If your workplace involves chemicals, SDSs are a great foundation for your fire safety program.

Fire Safety Equipment

Both OSHA and NFPA require that facilities have equipment for fire detection and suppression in place, and incorporated into the fire prevention plan. This equipment includes fire suppression systems, smoke alarms, and fire extinguishers.

Sprinkler systems are commonly used to douse a fire. However, it’s important to keep in mind that automatic sprinklers are technically different than fire suppression systems; some fires need to be suppressed by other types of liquids or foams, depending on the materials or equipment involved. Suppression systems also aim to protect an area rather than simply extinguish flames. Common examples include:

- Dry chemical suppression, which douses flames caused by flammable or combustible liquids. This is often used in furnace rooms, mechanical rooms, or areas where flammable liquid is stored.

- Wet chemical suppression, which forms a type of vapor foam that prevents materials from re-igniting. It is mostly used in kitchens.

- Carbon dioxide, which doesn’t require additional clean up or leave behind a residue. This is most often used in computer rooms and archival rooms.

Smoke alarms detect both smoldering and flaming fires. You should wire all your alarms together so if one goes off in your facility, they all go off. Alarms should be tested once a month, and replaced completely after ten years. Just as smoke alarms save lives during house fires, they save lives in the workplace and are essential to evacuating a facility quickly and efficiently.

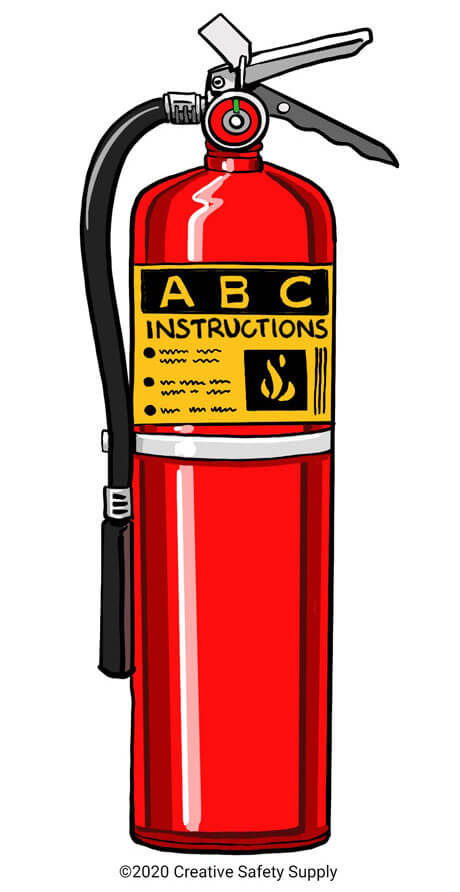

Fire extinguishers are one of the most important pieces of fire equipment a facility can have. NFPA 10 provides the standard for portable fire extinguishers, which are meant to be the first line of defense against fires that are limited in size. Facilities are required to have fire extinguishers, and these must be inspected regularly, properly charged, highly visible, and easily accessible.

Like fire suppression systems, there are different types of extinguishers that are meant to douse flames from certain materials. It’s critical to use the correct extinguisher for the situation, as the wrong one can make things even more dangerous or increase the risk of hazards such as electrical shock or explosions. Each extinguisher is sold with a class rating that is identified with a letter and symbol for the type of fire it will be able to put out:

- Class A Rating, identified by the letter A inside a green triangle. These extinguishers are intended to douse fires from ordinary combustible materials such as cloth, plastic, wood, and paper.

- Class B, identified with the letter B inside a red square. There are meant to put out fires that are caused by flammable liquids such as paint, oil, and gasoline.

- Class C, a letter C inside a blue circle. These were designed to fight fires that involve live electrical equipment and contain specific nonconductive extinguishing agents. Once equipment has been de-energized, a Class A or Class B extinguisher may be used.

- Class D, a letter D inside a yellow star. These are used to douse fires from combustible metal alloys and other types of combustible material, and contain agents that specifically won’t react with the burning metal.

- Class K, a letter K inside a hexagon. These are meant to be used on fires from cooking media such as grease, animal fats, and oil. They create a soapy foam that holds in steam and vapors to extinguish the fire.

Some fire extinguishers are designed to be used for more than one type of material or fire, and are identified as either ABC or BC extinguishers. Employees should be trained on the different class ratings, especially if their workplace involves unique materials such as electrical equipment or cooking media, so they understand how to correctly douse a fire in their area.

PPE for Fire Safety

Firefighters are required to wear extensive personal protective equipment. Most workers don’t need this type of PPE during day-to-day operations, However, there is fire safety PPE available for people who consistently work in situations where there is an increased risk of a fire breaking out. There is flame-resistant clothing for workers who work with flammable liquids or chemicals, in kitchens, in welding, or with saws and other types of equipment that may set off sparks. Flame-resistant clothing (FR clothing) is labeled with a Hazard Risk Category that is established by the NFPA. The higher the rating, the higher the level of protection.

It should be noted that FR clothing is not the same as flame-retardant clothing. Flame-retardant contains materials that are chemically treated, while FR clothing is made from materials that are naturally resistant to flames. FR clothing is additionally not the same as arc-rated (AR) clothing. AR clothing is rated to specifically protect employees from electrical arc hazards, and according to NFPA 70E standards, the appropriate FR and AR PPE must be separately donned before electrical work is conducted.

Requirements for a Fire Emergency Plan

An essential aspect to fire safety is implementing an emergency response plan in your facility. Hopefully a fire will not occur, but every facility should be prepared for one and take these preparations very seriously by following established standards and fire safety guides.

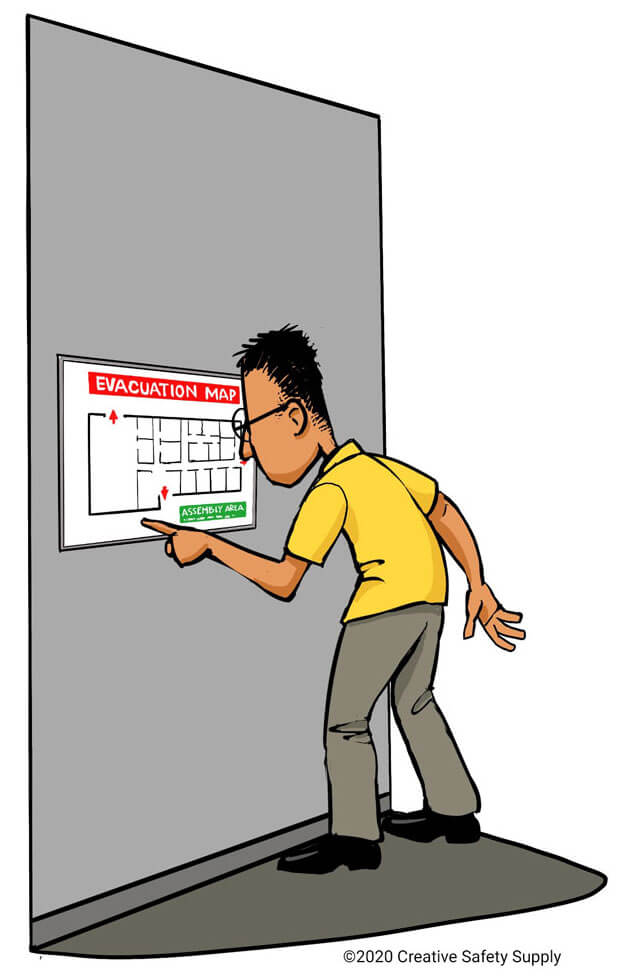

Each employee should understand the actions to take in the event of a fire and how to get away as quickly and safely as possible. An understanding of emergency exits and paths should be introduced during training. Evacuation maps and visual communication are required by OSHA standard 1910.39 so that workers may find guidance during an actual emergency. Maps that show a layout of your facility and the location of emergency exits should be easy to read and posted in high traffic areas. OSHA additionally provides key requirements for emergency exits. Facilities need at least two exit paths and emergency exits that are clearly identified, never blocked, and lead to the outside of the building.

Tools such as wayfinding signs and glow-in-the-dark tape are materials that reduce confusion and cut down on the amount of time it takes to evacuate, which may save lives. Photoluminescent markings in particular can help, as many fires cause the power to go out.

Fire safety in the workplace examples

Maintaining a safe work environment is paramount, and fire safety plays a crucial role in achieving this goal. Here are some essential fire safety measures that every workplace should implement:

- Fire Prevention Plan: Develop a comprehensive fire prevention plan that outlines procedures for identifying and mitigating fire hazards. This plan should encompass regular inspections of electrical systems, proper storage of flammable materials, and the enforcement of safe work practices to minimize ignition sources.

- Fire Hazard Identification and Control: Proactively identify and manage potential fire hazards within the workplace. This includes flammable liquids, combustible materials, and electrical equipment. Implement safe storage practices for these materials, keeping them away from heat sources and ensuring proper ventilation.

- Emergency Exits and Signage: Ensure all exits are clearly marked and unobstructed at all times. Maintain proper fire exit signage that is illuminated and visible even during a power outage. Conduct regular inspections to confirm functionality of fire doors and emergency exits.

- Fire Suppression Equipment: Provide appropriate fire extinguishers throughout the workplace, strategically placed near potential hazards. Employees should be trained in the proper use of these extinguishers for different fire types. Additionally, consider the installation of fire sprinklers, which can significantly suppress fires and limit damage.

- Employee Fire Safety Training: Regularly train employees on fire safety procedures, including how to sound the alarm, evacuate the building safely, and potentially use a fire extinguisher if they are comfortable doing so. Fire drills should be conducted periodically to ensure everyone is familiar with the evacuation plan and understands their roles in an emergency.

- Housekeeping and Maintenance: Maintain a clean and organized work environment. Regularly dispose of combustible waste materials and clutter that could contribute to a fire's spread. Ensure proper maintenance of electrical equipment and machinery to minimize the risk of overheating or malfunctions.

By implementing these fire safety measures, workplaces can significantly reduce the risk of fires and ensure the safety of employees and property in the event of an emergency.

Employee Training for Fire Safety

If a fire breaks out in your facility, employees rely on their training to ensure their safety. While certain occupations, such as welders and electricians, require high levels of training, every employee in any occupation should be trained on general prevention and safety strategies so they understand how to keep their area—and themselves—safe. OSHA 1910.39 establishes general training requirements that each employee should receive, which covers:

- An understanding of the fire hazards and potential ignition sources within their vicinity. This is often the first step in a fire safety program.

- Emergency exits. Training should cover the locations of the exits, how to identify them, and which ones are nearest to an employee’s typical location.

- Fire drills. These should be conducted regularly so workers can practice what to do and where do go in the event of a fire.

- Fire extinguishers. If extinguishers are provided for employee use, the employer must implement training so workers are familiar with the principles of the extinguisher and how to use it. This training should be conducted when the worker is first hired, as well as once a year, and needs to include what type of fire extinguisher should be used based on the materials in the area.

Additional training may be necessary depending on the risks and operations associated with the facility. The employer is responsible for identifying these additional needs and providing appropriate training. Extensive preparation and a basic understanding of fire safety for each worker in your facility is critical to avoiding fires in the first place, and to ensuring that both lives and property are saved if one does break out.

Similar Articles

- Fire Prevention in the Workplace [OSHA 1910.39]

- NFPA 25: Standards for Fire Protection Systems

- Addressing Biohazard Safety in the Workplace

- Improving Workplace Electrical Safety

- Fall Protection in the Workplace: OSHA’s Guidelines

- Floor Marking for Fire Extinguishers

- Mine Safety & Health [Expert Advice]

- Job Hazard Analysis: Addressing Coronavirus Risk in Your Workplace

- Preparing the Workplace with Emergency Action Plans (EAP)