A quality circle is a small group of 3 to 12 employees within an organization who regularly meet to identify, analyze, and solve work-related problems with the goal of improving overall quality and productivity. Originating in Japan in the 1960s, they became a popular approach to quality management and employee empowerment. Today, quality circles continue to be used in various industries and organizations globally, adapting to different contexts and incorporating modern techniques.

Let’s explore the origin, process, benefits, essential tools, evaluation methods, and implementation of quality circles, along with real-life examples.

History of Quality Circles

Quality circles originated in the 1950s, with the concept first introduced by W. Edwards Deming. Toyota liked the idea and began using it in a variety of ways throughout its manufacturing facilities and other areas. By 1978, Japan had a massive adoption of quality circles, with over one million circles involving ten million workers.

The concept of quality circles has somewhat fallen out of favor in many Western countries over the past couple of decades. It was a very popular option throughout the 1960s, 70's, and 80's. Some companies are beginning to realize how quality circles can be effective again, especially when combined with other methodologies like Lean, Six Sigma, and more.

Quality Circle Process

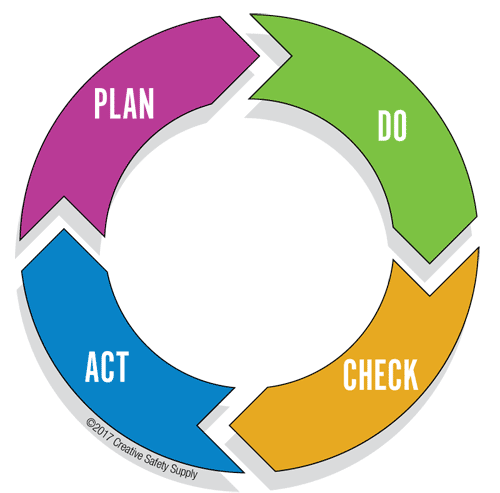

Quality Circles follow a structured process of problem-solving and continuous improvement, often utilizing the Plan-Do-Check-Act (PDCA) cycle. The process involves identifying issues, analyzing them, generating solutions, implementing those solutions, and then evaluating the results to ensure continuous improvement.

Following this process not only makes it easier to identify potential solutions and implement them, but it also has an established flow for moving from one process improvement to the next. This is important because this type of group meeting is scheduled to take place on a regular basis, with new problems being identified and resolved on a regular basis.

Quality Circle Examples In Practice

Many companies today use quality circles, especially when it comes to manufacturing. The most well-known example would be Toyota, which helped to pioneer the concept decades ago. These circles continue to meet on a regular basis to identify potential problems and get them resolved as efficiently as possible.

Another example would be Lockheed Martin. Lockheed Martin began using quality circles in their manufacturing facilities back in 1974. Executives from this company learned of quality circles when visiting Japanese manufacturing plants, and saw how beneficial they could be. Soon after Lockheed Martin, a number of other US companies added them to their workplaces, including GM, Northrop, and Westinghouse.

These are good examples of large corporations using quality circles on a broad scope. Looking some of the ways a quality circle can work in an average manufacturing facility can be just as effective. The following are some examples of how a typical quality can provide benefits to the workplace.

- Discussing Best Practices - In many workplaces, there are multiple shifts of people who do the same or similar work. By getting everyone together in one place, it is possible to identify which shift is working most efficiently, and use that to create best practices that can be followed across all shifts.

- Pointing Out Issues - Employees often know of lots of minor (or even major) issues, but they assume that someone else is working on getting them fixed. When a quality circle meets, they can discuss these types of issues, and take ownership of them to actually move forward with a positive result.

- Collaborating on Solutions - One of the biggest examples of how a quality circle can help is that it is the actual employees who are working to come up with solutions to problems. Those who have to deal with the problems are typically the best people to fix it. Since they are also working on the issue themselves, there will be far less pushback on a proposed solution.

- Brainstorming Ideas - When a circle meets, everyone will be familiar with the position so they can more easily bounce ideas off of each other. Brainstorming ideas is a very effective way to arrive at the best possible solution to a problem.

- Streamlined Problem Solving - If management or another outside group tries to come up with solutions to a known problem, it will take a lot longer to learn about how things are done, and how a problem can be fixed. Those with experience in the department won't need to waste time learning about the problem before proposing solutions.

Quality Circle Tools

A quality circle can use any type of tools that they would like to help improve their roles. Some of these circles are more casual and just talk about different issues with their jobs, and propose solutions. In this type of situation, a simple notepad could be sufficient. While this can be a good place to start a quality control circle, it is best if they evolve into something more formal where more detailed problems can be addressed.

When this happens, some of the following quality improvement tools are often incorporated to help discover the root causes to issues, and how to fix them.

- Flowcharts

- Scatter Plots

- Run Charts

- Graphical Tools

- Process Mapping Tools

- Pareto Charts

- Fishbone Diagrams

There are many other potential tools that a group could use depending on the specific problems they are trying to overcome. When equipped with the right tools, a quality circle is able to more efficiently identify issues, and propose solutions, which is the main goal of these groups.

Quality Management System

Quality circles are considered a quality management system, which is a collection of different business processes that are designed to help improve the ability of a company to meet customer requirements. The quality circles should always keep this in mind when meeting or coming up with new ideas.

Any problem that is discovered by the quality circles needs to be solved in a way that meets the guidelines of a quality management system. Specifically, this means that it needs to be in line with something that customers are actually demanding. Companies that don't keep this in mind often end up creating a lot of waste by having features or options that customers may use, but they would not be willing to pay more for.

Measuring Success of Quality Circles

Quality circles need to track their performance with data to confirm positive impacts on the workplace. Gathering baseline data before implementing solutions, tracking progress, and demonstrating the results of their actions is crucial. This data-driven approach validates the value of quality circle efforts and secures future support. While it might seem time-consuming initially, the benefits of demonstrating success will be well worth the effort.

Some of the key metrics to measure the success of quality circles include productivity, defect rates, cost savings, and employee/customer satisfaction, along with organizational outcomes like ROI and cost-benefit analysis.

Implementing Quality Circles

When implementing quality circles, it is important to provide some guidance to the groups to get started. Companies that simply ask different departments to get together once a month to discuss how things can be improved will often find that the meetings are unproductive, and end up turning into a waste of time.

A company will often have one person who has become an expert in quality circles and how they work attend meetings with each circle for the first several times. This can provide some direction on how things should be done, and they can answer any questions that the attendees have. It is important to ensure that the expert doesn't try to take over the circle, or have the circle become overly reliant on them though, since this should just be a temporary thing to get things up and running.

Quality circles should be measured based on their success in improving the productivity of their department, eliminating waste, and otherwise benefiting the company. If the quality circles become unproductive, the expert in this area can be brought back in to provide additional direction to the group.

Resources

- https://en.wikipedia.org/wiki/Quality_management_system

- https://www.referenceforbusiness.com/small/Op-Qu/Quality-Circles.html

Similar Articles

- Quality Control in Manufacturing

- Understanding Total Quality Management

- Quality Management Systems (ISO 9001:2015)

- Quality Control

- William Edwards Deming: The Father of Quality Management

- Quality, Health, Safety, Environment (QHSE) Management Systems

- The Five Whys (Root Cause Analysis)

- 5 Lean Principles for Process Improvement

- Continuous Improvement (A Kaizen Model)

- 8D for Problem Solving