The five whys concept is a way to try to find causes of potentially complex problems. When done properly, this strategy will help you to get to the root cause of many types of issues so that it can be addressed, rather than just focusing on symptoms of that problem.

This strategy has been shown to not only be effective, but also easily used on a wide range of issues throughout many different industries. The five whys can also be combined and used with a variety of other techniques used to identify and solve workplace problems.

History of the 5 Whys

The five whys technique began at the Toyota Motor Company with Sakichi Toyoda. This system was implemented throughout their manufacturing facilities as part of their overall methodological strategy. It was the basis of their 'scientific approach' to problem solving. Since then, this method has been spread out through just about every type of industry around the world, and is a component of Kaizen, Six Sigma, and lean manufacturing.

What Is Five Whys?

The five whys process is, as the name implies, a process where you ask why five times in order to get to the root cause of a problem. The process starts out with a clearly identified problem, and then keeps asking why things happened until the true root of the issue has been discovered. Looking the five whys examples can help to better understand this process.

One of the best ways to get a good understanding of the five whys is to look at examples of how it can be used in the real world. The following example is commonly given to discover the root cause of a car that will not start. So, "The Car Will Not Start" is the initial problem, which is written at the top. From there, the person using the 5 whys would ask these types of questions:

- Why Won't the Car Start? - Answer: The battery is dead

- Why is the Battery Dead? - Answer: The alternator is not working properly

- Why isn't the alternator working? - Answer: The serpentine belt has broken

- Why did the serpentine belt break? - Answer: It was not replaced when worn

- Why wasn't it replaced? - Answer: The owner did not follow the recommended service schedule

The last why is the root cause of the problem. If the owner of the vehicle would have followed the recommended service schedule, this issue would not have happened. Not only that, but following the recommended service schedule will help to prevent a wide range of other problems in the future.

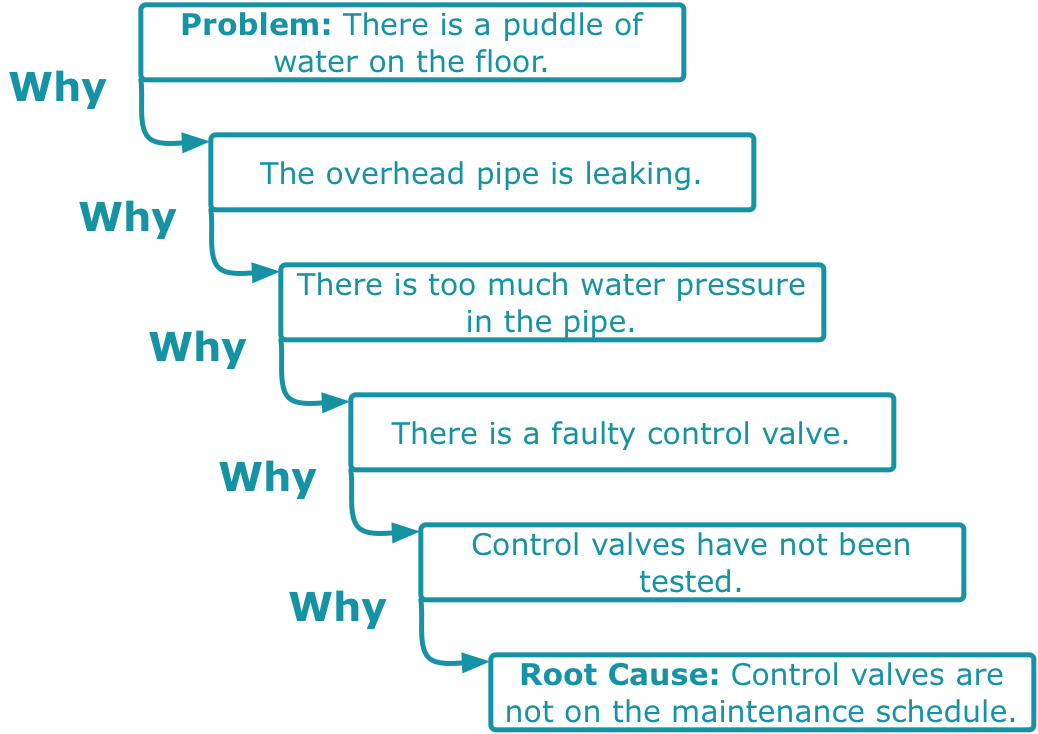

Another example of the 5 whys system can be observed in this image:

Using 5 Whys for Root Cause Analysis

The primary goal of the five whys is to take a problem and find the root cause so it can be addressed. When done properly, a company can find the root cause of the problem so that they can take actions to prevent it from happening again in the future.

One of the best things about the five whys is that it is extremely inexpensive to implement. A company can begin using it without spending a dime, and only using the time it takes to go through the process. Over time, this solution can be expanded to better track the information that is gathered so it can be used for future efforts.

Why Look for the Root Cause

Most companies have come to the conclusion that while it may be faster to identify a problem and put in a fix for it up front, in the long run it is much better to identify the true root cause of the issue. Seeking a root cause solution rather than just addressing the symptoms provides companies many long term benefits, including:

- Reduced Risk of Reoccurrence (by dealing with the root cause, the symptoms are less likely to happen again in the future)

- Preventing Problems Before they Occur

- Gathering Information for Identifying Other Issues

- Being More Aware of How a System Works

- Quality over Speed

Every workplace is unique, and all workplaces have their own set of problems that they need to deal with. Implementing the usage of the five whys can help companies in any industry to better understand their issues, and give them a more clear roadmap on how they can be addressed permanently.

Root Cause Analysis Tools and Techniques

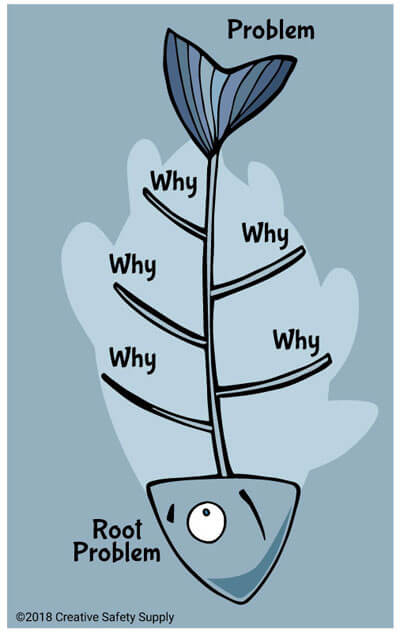

There are two primary techniques that are used for conducting the 5 whys. They are known as an Ishikawa diagram (or fishbone diagram), and the tabular format.

The fishbone technique gets its name from the look that is developed when writing it down on a piece of paper. You can see an outline of a fishbone technique in this image:

In this option, the tail of the fish is the main problem, each of the whys goes along the sides, and the final effects (or root cause) are up front. This allows those performing the analysis to easily write down known problems along with the whys that helped to find them.

The tubular technique can be written out in a variety of ways, but it will typically either be vertical, as in the image below, or have a 'step down' look that moves from left to right, top to bottom with each of the whys.

The Rules of the 5 Whys

The five whys system can be customized based on the specific needs of a given facility. Most companies that are implementing this type of strategy will use some general rules or guidelines that can help keep the strategy focused. The following rules of performing the 5 whys are generally a good place to start for most situations:

- Form the Why Questions from the Customer's Point of View

- Ask Why Until Root Cause is Discovered (even if it is more than five times)

- "Human Error" is not a root cause. Why did the human error occur, and what can be done to prevent it!

- This strategy is looking to find problems, not place blame.

- All statements should be based on facts, not assumptions.

- Go through the why statements step by step. Never jump to a presumed root cause.

- Use paper or a whiteboard rather than a computer program to track the Whys (info can be entered into a program later).

- Make sure to clearly distinguish the causes of problems from the symptoms of the problem.

- Engage management and other teams as needed.

- Invest the necessary time to find the root cause.

- Focus on long term success rather than short term uptime.

These can be seen as a good starting point for companies; additional rules and guidelines can be added as needed.

Trouble with Five Whys

While the 5 whys is widely recognized as an effective way to identify the root cause of problems, it does have some issues that need to be made known. Once a facility becomes aware of potential issues, they can take steps to avoid them.

Some of the most commonly cited problems are:

- People often identify a symptom as a root cause. It can take a significant amount of practice to consistently dig down to the true root cause.

- This process isn't always consistent. Different people performing the analysis on the same problem will often come up with different answers.

- When using the 5 whys, people usually stop the process once they have found a root cause to the problem. In situations where there are multiple root causes contributing to the problem, this can be an issue.

- The process is limited to the knowledge that the person performing it has. It requires knowledge of the problems to be able to ask the right 'why' questions.

Most of these issues are easily resolved through training and experience. It is also important to be aware that the five whys doesn't have to be used as a stand-alone strategy. It is often used along with other solutions to help drive an investigation toward the root cause.

Training and Implementation

One of the best things about this strategy is that it is fairly easy to learn. There aren't any extremely complex concepts that need to be taught. Instead, employees can begin using this option right away with just a brief explanation of what it is and how it works.

The easiest way to ensure everyone is correctly using the strategy is have them complete the process problems that they find. A trainer can then provide insights as to how to ensure they are getting to the root cause without making any leaps of logic or breaking any of the above mentioned rules.

This can take some trial and error, but even when the five whys aren't conducted perfectly, they can still help to lead people in the right direction, which is always beneficial. The 5 whys can also be incorporated into other methodologies, and training can be included in that process.