Resources

Facility Efficiency Articles

Understanding The Lean Agile

Tired of wasted time & resources? Master Lean Agile for faster delivery, happy clients & a more productive team. Learn more! …

What is Lean in Business?

Lean in business means getting the most value while wasting as little as possible and finding ways to improve processes throughout the entire value chain. …

Understanding The 5S Methodology Implementation

This guide highlights important strategies to implement the 5S of lean. Discover the benefits, and utilize the tools to streamline the manufacturing processes. …

Advanced Kanban: Optimizing Complex Systems

Kanban offers a simple and visual approach to managing complex systems that teams from different backgrounds can easily understand and implement. …

Heijunka (Production Leveling)

Heijunka is a Japanese word that means leveling. It consists of a lean manufacturing tool that helps companies level production and thus satisfy demand and reduce waste. …

Lean versus Six Sigma: Which is better for your business?

Successful businesses actively incorporate business management techniques such as Six Sigma and the Lean method in their operations to help reduce inefficiency and maximize profits, but which strategy is right for you? …

Control Charts: A Basic Component of Six Sigma

Statistical process control charts are a helpful visualization tool for recognizing deviation within a process. These charts help operators know when to take action. …

Choosing to Implement a Periodic Inventory System

Read up on periodic inventory systems to make an educated decision on whether this inventory valuation system is right for your company. …

Peter Drucker: The Founder of Modern Management Studies

Known as the founder of modern management, Peter Drucker published 39 books and was an incredible resource as society transitioned into the 21st century. …

James Womack and the Creation of the Lean Enterprise Institute

Learn all about James Womack, the author of The Machine that Changed the World and the founder of the Lean Enterprise Institute, a notable figure in Lean history. …

Shigeo Shingo and the Importance of Operational Excellence

Learn all about Shigeo Shingo and the contributions he made to the world of Lean manufacturing, quality control, and overall operational excellence. …

The Origins of TPS

Explore The development of the Toyota Production System through the eyes of three of its most influential founders: Kiichiro Toyoda, Eiji Toyoda, and Taiichi Ohno. …

Frank and Lillian Gilbreth: Standardization, Ergonomics, and Lean Manufacturing

Frank and Lillian Gilbreth implemented motion studies to eliminate unnecessary movement during a process. They were the inventors of ergonomics. …

Henry Ford and Development of Assembly Lines

Learn all about the origins of Mass production and assembly lines in manufacturing with this article. It all started with Henry Ford. …

ISO 31000:2018 – Risk Management

Explore the ISO 31000 risk management guidelines in this article! The principles, framework and process will be gone over in depth. …

Autonomous Maintenance: The Key to a Healthy TPM Program

Autonomous maintenance is an important part of Total Productive Maintenance strategies. This is done by handing over simple maintenance tasks to machine operators. …

A Look at Training Within Industry (TWI)

Training within Industry, or TWI, uses a series of training modules to develop leaders within a business that then train new employees quickly and effectively. …

A Complete Guide to QR Codes

QR codes can be put to use in a variety of instances due to their ability to hold an astounding amount of information in comparison to other more common barcodes. …

What is a CMMS? (Computerized Maintenance Management System)

A CMMS allows for the users to easily keep track of information needed for preventative maintenance to keep equipment and workflow running as intended. …

Staying Lean During a Pandemic

It’s important to stay focused on efficiency as the COVID-19 pandemic continues. Here are several Lean manufacturing techniques that can help your business continually improve, even during times of crisis. …

Creating an Effective Warehouse Storage Numbering System with Barcodes

To streamline operations and prevent waste, warehouses must be organized. An effective warehouse storage numbering system helps workers locate and pick items as quickly as possible. …

What is Logistics Management? (Supply Chain)

Logistics management ensures that the right product is delivered to the right customer, at the right price and the right time. Learn how logistics can help you reduce costs and improve efficiency. …

Understanding the SIPOC Diagram in Six Sigma

Creating a SIPOC diagram to determine the Suppliers, Inputs, Process, Outputs, and Customers of an operation can help businesses achieve improvement and ensure Six Sigma success. …

Understanding Design for Six Sigma (DFSS)

DFSS is an improvement technique that uses the DMADV approach to ensure that a product or service meets customer expectations as it is originally introduced to the market. …

Automated Guided Vehicle Lane Marking

AGVs exist in large facilities to help with consistency and safety. Used for manual labor, AGVs are able to reduce steps in processing to focus on other priorities. …

Rack Labeling

A rack labeling system can vastly improve the efficiency of any warehouse. Barcodes and other rack labels enhance inventory management and allow workers to quickly find items. …

6S: Safety

Safety is the additional sixth step to the traditional 5S method. A company that implements 6S focuses on improving organization and efficiency, with an emphasis on safety throughout each step. …

Quality Control

Quality Control helps ensure products are meeting customer needs and reduce the risk of product defects. Let this article help get you started. …

Kaizen and Lean Manufacturing

Going “Lean” is all about continuous improvement. Kaizen gives Lean manufacturers the tools and strategies they need to identify wastes in their facility and effectively eliminate them. …

A Brief History of Kaizen: The Key Players

Kaizen has been shaped over the years by an automobile manufacturer, American statisticians, influential businessmen, and more. We explore who had a hand in creating Kaizen and how it has developed into the philosophy we know today. …

An In-Depth History of the Kaizen PDCA Cycle

Lean organizations focus on improving all parts of a process from start to finish in order to increase the quality of the results. Through the use of specific cycles (like PDCA), organizations can improve the processes and end products. …

Quality Management Systems (ISO 9001:2015)

ISO 9001: 2015 is a standard that outlines and defines requirements for a quality management systems. This QMS certification allows companies to demonstrate to clients that they take quality and efficiency seriously. …

Implementing Kanban

Kanban’s inventory system has transformed the way the world manufactures. This article outlines how to implement Kanban successfully and efficiently. …

DMAIC Cycle

The DMAIC cycle is the foundational method of Six Sigma, the Lean manufacturing method that radically reduces defects in production and infinitely improves efficiency. Learn how to implement Six Sigma into your facility with DMAIC. …

Quality Control in Manufacturing

Quality control in manufacturing is essential to maintaining a good customer base and keeping rework costs down. …

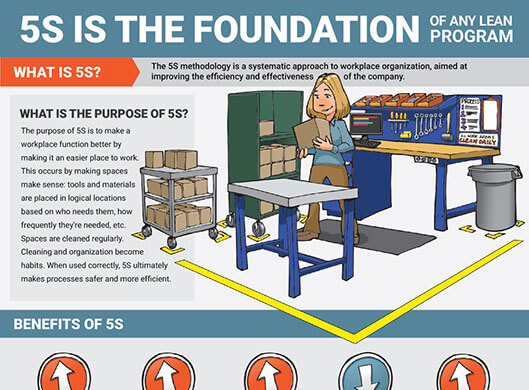

5S Lean Training

If you’re new to the concept of 5S, you’ve probably feel confused. This article aims at providing clarity and setting you on the path toward understanding 5S and Lean. …

Kanban Production System

Kanban Production Systems are an organizational system that produces big results by taking a series of small steps. Find out more... …

Barcode Labeling

Barcode labeling can help improve efficiency and overall accuracy when working with individual items. Learn how barcode labeling can help improve your business today. …

Six Sigma Certification

Are you wanting to learn more about Six Sigma certification? Review this basic information on what it takes to become Six Sigma certified. …

Critical Path Method

The critical path method (CPM) is a tool for planning and managing projects. The method can help you create and execute a project schedule, and it’s designed to maximize efficiency. …

Mass Production

Mass production is simply the manufacturing of a large number of identical or very similar products. This type of production has been around for a long time, and it has its advantages and disadvantages. …

House of Lean

The house of lean involves strategic planning and understanding to establish results of efficiency, safety, and process improvement. …

What is QCDSM?

QCDSM: Quality, Cost, Delivery, Safety and Morale. Learn how this simple lean principle can help your business. …

8 Wastes of Lean [A Guide to Manufacturing Wastes]

The 8 Wastes of Lean is a much-needed update to the what the Toyota Production System called the 7 Wastes of Lean. Fighting these wastes head on will help your facility run more smoothly and efficiently. …

Supply Chain Integration

Supply chain integration refers to the process of integrating all parts of fulfillment into one single system. Learn the steps to get your supply chain integrated into an easy-to-manage system. …

Organizational Development Process

Organizational development process is an improvement methodology designed to take known problems and implement changes in order to overcome them. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

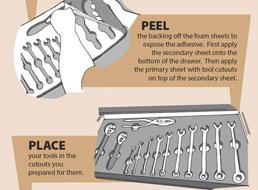

Tool Storage Ideas

Lean manufacturing emphasizes organization, but it can be difficult figuring out just how to get started. This article lays out some common and effective ways of getting organized quickly. …

Value Stream Mapping (VSM Analysis)

Value stream mapping (VSM) gives a comprehensive look at a business’s production process. Once a business has their process mapped out, it’s easy to identify the places where waste happens. …

What is Jishuken?

Are you a leader looking to understand the benefits of Jishuken? We breakdown the definition of Jishuken and how it can improve efficiency in your workplace. …

Lean Healthcare (Principles for Improvement)

Implementing lean healthcare in the medical field will lead to improvement in overall performance and patient satisfaction. …

Floor Marking for Factories

Factories are busy, active environments with a lot happening at all times. Floor marking is a low-cost way of improving efficiency, safety, and organization. …

Floor Marking for Facility Safety

The best way to enhance safety is keeping workers informed, and floor markings are the most reliable, durable method of ensuring that everyone is aware of potential hazards. …

Perpetual Inventory System

Using a perpetual inventory system is a great way to keep track of inventory, ordering, and other related tasks in order to keep your business running efficiently. …

Industrial Floor Marking Guidelines

OSHA doesn’t offer much guidance on how floor markings should be installed, so we’ve compiled some helpful tips and best practices to ensure your markings are useful, straightforward, and helpful to everyone in your facility. …

Electrical Wiring (Wire Color Codes)

Proper electrical wiring is not the place for uncertainity. Fortunately, Wire Color Codes exist to protect you from harm, while ensuring that the lights stay on. …

Theory of Constraints

Whether you know it or not, something is holding your business back, and the Theory of Constraints can help you find it. …

Calculating Overall Equipment Effectiveness (OEE)

Are your lean and 5S efforts making a difference? Crunch the numbers on OEE to find out! …

Total Productive Maintenance

Learn how you can reduce downtime, improve efficiency, and enhance employee morale all in one fell swoop with Total Productive Maintenance. …

8D for Problem Solving

The 8 Disciplines (often seen as the acronym “8D") is a problem-solving method initially developed by the Ford Motor Company to resolve a wide variety of problems in any professional environment. Find out how the 8D method can benefit your workplace. …

What is Lean Logistics?

Lean logistics is a detailed implementation or organization of an operation that is more complex in nature than what you see in standard lean strategy. …

Kano Model (Analysis & Diagram)

Using the Kano model is beneficial when evaluating what your consumers like, need or expect from your product or services. Learn more... …

Statistical Process Control (SPC) in Manufacturing

Statistical Process Control also known as SPC, is a term used in quality control. Find out how you can use this continuous improvement method. …

Bottleneck Analysis

Learn to avoid hang ups that lead to bottlenecks with these helpful tools and tactics to improve quality and efficiency. …

Quality Circle

Quality circle is a group of employees within the same job role that collaborate together to discuss ways to fix or improve processes. Learn more › …

Warehouse Management

Proper warehouse management can dramatically improve both efficiency and safety. This article covers everything you need to know. …

Six Sigma Principles

Find out how to properly implement six sigma principles to promote success in your business. …

The Five Whys (Root Cause Analysis)

Finding the root cause of a problem is imperative in problem solving. The "five whys" will help you find the root cause and prevent future issues. …

5 Lean Principles for Process Improvement

Learning the basics about the lean process is essential when implementing continuous improvement changes. We have broken down the lean process so its easy to understand. …

Fault Tree Analysis

Understanding fault tree analysis can help you find the root cause to an issue to help it become resolved. Learn about implementing fault tree analysis in your industry. …

Toyota Production System (TPS & Lean Manufacturing)

The Toyota Production System, or TPS, brings improved organization to a facility, reduces waste, and can improve the bottom line of companies that adopt it. …

Introduction to Process Mapping

Process Mapping is used in many types of businesses to help companies streamline their production, increase profitability, reduce waste, and much more. …

Balanced Scorecard [Definition + Examples]

A balanced scorecard is an effective management system that helps organizations better accomplish their goals and can be used effectively any type of business. …

Continuous Improvement (A Kaizen Model)

Facilities that focus on continuous improvement become more competitive over time and can maintain their advantages in their industry, but only if the improvement efforts are done correctly. …

Process Cycle Efficiency (PCE)

Process Cycle Efficiency is a metric commonly used by those following Lean and/or Six Sigma principals. It is calculated by taking value-added time and dividing it by lead time. The answer is a percentage, and the goal is to be as close to 100% as possible. …

Value-Added vs. Non-Value-Added Activities

The terms value-added and non-value-added are often used when evaluating changes in products, workflow production and process improvement. Categorizing activities will help identify what activities should be maintained and which ones should be adjusted or eliminated. …

Visual Factories

Visual factories use signs, posters, charts, labels and floor marking to provide information that improves efficiency, safety and productivity in the workplace. This is a fairly simple concept that yields excellent results. …

How to Implement 5S in an Organization

It takes significant effort to implement a proper 5S program, but following the right steps will drive success and help the process go smoothly. …

Getting Started with Kaizen

Proper training is key for getting started with Kaizen and on the road to continuous improvement. …

Floor Marking Ideas for Warehouses

Warehouse floors provide an opportunity for visual communication. Find out what floor signs, tapes, and shapes you can use. …

Genchi Genbutsu

Genchi genbutsu, a Japanese term meaning “go and see,” can change how managers and company leaders interact with the workplace. …

Types of Floor Marking

Many options exist for marking floors. Learn about floor tapes, virtual floors signs, and more. …

Lean Supplies

Learn what supplies and tools you can use to make Lean manufacturing efforts successful. …

Kanban Training and Research

A kanban system uses visual cues to trigger actions. Find out how it can regulate production. …

The 5S System [Lean Manufacturing Methodology]

One of the most comprehensive pages you will find on 5S. …

Tool Box Organizers – 19 Tips & Hacks for Your Tool Box

Use these tool foam organizer tips and hacks get your workspace in order and simplify your life. …

Facility Efficiency Questions and Answers

What are some Examples of Successful Approaches to Facility Efficiency?

Successful facility efficiency is made up of a range of different strategies and practices that allow businesses to maximize their output and streamline their daily processes. In the competitive landscape we see today, adopting modern technologies and strategies is a must to achieve efficiency, reducing ongoing costs while gaining a competitive edge. In this article,… …

What are the best Tactical Planning Strategies for Success?

In a world that's rapidly changing, success is no longer about simply working harder - it’s about working smarter. With the right tactical planning strategies at your fingertips, you can turn any challenge into an opportunity for growth and success. Tactical planning is the process of breaking down a long-term strategic plan into smaller short-term plans… …

What is the difference between Nominal and Ordinal?

Nominal scale is a method used to categorize variables with corresponding numbers assigned for data analysis. Ordinal scale involves arranging information in a specific order and ranking each parameter accordingly. There is a rank associated with each answer option, representing their relative differences but the difference between two ranks may not always be equal. For… …

What are the Best Quality Management Techniques?

Quality Management is the process of ensuring that products or services provided by an organization meet customer needs and expectations. Implementing a Quality Management System (QMS) can improve performance, reduce waste, lower costs, ensure compliance with regulations, facilitate training opportunities, define/improve/control processes, and communicate readiness to produce consistent results across your organization. A robust QMS… …

What is Scientific Management?

Are you frustrated by inefficiencies and low productivity in your business operations? Perhaps it’s time to turn to proven strategies that continue to deliver exceptional results — the principles of scientific management. This timeless philosophy has been shaping prosperous organizations worldwide for a long time, enhancing not only their efficiency but also significantly bolstering bottom-line… …

What Is the Factory System?

Shaping the business landscapes of tomorrow, the Factory System continues to break boundaries, propelling businesses into a new era of profitability and growth. This dynamic system is revolutionizing the way we understand production and efficiency in our fast-paced 21st century marketplace. But how exactly can it unlock untapped potential in your business? Dive in for… …

What Does Productivity Really Mean?

Are you constantly grappling with the complexities of project management, struggling to streamline operations, and seeking ways to optimize facility efficiency? Imagine a scenario where you're no longer overwhelmed by these tasks. Welcome to the realm of enhanced productivity in project management and facility operations – a realm where seamless execution meets resource optimization, resulting… …

What is the Theory of Constraints?

The theory of constraints is a type of management concept that looks at all obstacles to achieving more as being caused by a small number of different types of constraints. This theory can apply to any type of manageable system, but it is most commonly discussed when it comes to manufacturing, warehousing, and other related… …

How does workplace safety affect efficiency?

When looking at workplace efficiency strategies most companies focus on changing their processes, upgrading machinery, or other similar things. What often gets overlooked, however, is making workplace safety improvements. In many cases, improving workplace safety can help to increase the efficiency of the area as well. When there is an accident or injury in the workplace,… …

What are Some Tools for Improving Facility Efficiency?

If you are looking for ways to improve the efficiency of your facility, you will need to make sure that you have the right tools to do the job. While there are certainly some physical tools that can be used in pursuit of this goal, most companies will benefit more from technological tools and concept… …

How is Efficiency Sustainable in the Workplace Environment?

Most companies today put in a lot of effort toward improving efficiency in the workplace. This is done in a variety of ways that help to identify and eliminate all sorts of waste. While there are dozens of different efficiency improvement methodologies out there, the most popular with this goal is 5 (or 6) S.… …

How is Manufacturing Cycle Efficiency Found?

The manufacturing cycle efficiency facility is the amount of value-added production time divided by the total cycle time used for a task. For example, when manufacturing a new product, you would want to start by measuring the total amount of time that is spent on making the product from the moment its production begins until… …

How Can Efficiency be Measured in a Warehouse?

Keeping track of the efficiency of a business is extremely important. It provides you with a set of data to see how successful the business is that goes beyond simply looking at profits and losses. In many ways, the efficiency of a business is more important to know because it is something that you can… …

How is the Variable Manufacturing Overhead Efficiency Variance Calculated?

In just about every industry, one of the largest expenses is going to be from the hours that employees are working and the amount of time a machine is dedicated to a product. Calculating how many hours of work a project will require can be difficult, but it is very important for being able to… …

What are Some Ways to Make a Warehouse More Efficient?

Operating a warehouse takes a lot of work. In many cases, warehouse companies will begin their business with plenty of extra space and other resources, so operating with maximum efficiency is not a priority. Over time, however, it becomes clear that optimizing efficiency is the only way to remain competitive and allow for continuous growth.… …

Why is organizing the workplace important?

Keeping a workplace organized is essential for many reasons. Employers of all types should be aware of why it is important to have proper organization policies in place throughout every facility. In most cases, proper organization is going to be based on the specific factors of a given facility. Sometimes, however, it may be done… …

Why is efficiency important in the workplace?

Efficiency in the workplace is something that is always on the mind of management, stockholders, and other interested parties. Understanding why efficiency is so important in the workplace, and how it can benefit both managers and front-line employees, will help to get everyone on the same page. No matter which of the many different efficiency… …

What is maintenance downtime?

In manufacturing, “downtime” occurs when an unplanned event halts production for a period of time. This event can be a malfunction, repair, or changeover of tools or equipment. Maintenance downtime in particular is when a machine is not operating or being productive due to required maintenance work. Issues that cause maintenance downtime are: Parts getting… …

How can warehouse storage be improved?

When your warehouse isn’t operating as efficiently as possible, this can lead to downtime, long waits, and other wastes that cause customers to turn to competitors. It’s critical to make sure you are using the space and storage within your warehouse efficiently, as this provides accurate and quick shipments, and satisfied customers. While it may… …

What equipment is used in material handling?

Material handling equipment is machinery that stores, moves, or lifts items from one place to another. Primarily, this equipment relocates large loads and aids the in-house storage and handling of raw materials. The equipment may be either manual or automated, and while automated material handling can cost more up front, it boosts safety and efficiency… …

What is ISO 9001?

ISO 9001 is a globally recognized standard for quality management systems. Companies need to follow specific requirements in order to become recognized as ISO 9001. This set of standards can be sought by companies in any country, and of any size, which is one of the reasons that it is so popular and well known.… …

What does efficiency mean?

In business and manufacturing, efficiency is the measurement of how much waste is involved with producing a specific product or service. The more efficient something is, the less waste there is. While in most cases it is impossible to be 100% efficient, that should always be the goal. Companies that can work to constantly improve… …

What is supply chain management?

Supply chain management (SCM) is a process where a company analyzes and provides oversight to a product from its original point of origin all the way through to where it is consumed. This higher level view of the supply chain can help to identify areas where there is waste, delays, or other issues that can… …

![8 Wastes of Lean [A Guide to Manufacturing Wastes]](https://www.creativesafetysupply.com/content/images/articles/8-wastes-th.jpg)

![Balanced Scorecard [Definition + Examples]](https://www.creativesafetysupply.com/template/images/articles/balanced-scorecard-thumb.jpg)

![The 5S System [Lean Manufacturing Methodology]](https://www.creativesafetysupply.com/template/images/custom/resources-page/Articles-5S.jpg)