William Edwards Deming was an engineer, statistician, writer, professor, and management consultant throughout his entire life, all the way up to his death at the age of 93. He is well known for his work with Japan, post-World War II in the 1950s where he taught his theories on Statistical Product Quality Administration. In the United States, Deming is known for his work on the 14 points of management as well as for his System of Profound Knowledge theory.

Throughout his life, Deming was more well known in Japan than in his home country. It was only a few years before his death that he began to gain widespread recognition for his work on continual improvement in the United States.

This article will address the question of who Deming was as well as the incredible work he did in terms of contributing to continuous improvement, efficiency, quality control, and of course, Lean manufacturing and the Toyota Production System.

Who Was William Edwards Deming?

William Edwards Deming was born October 14th, 1900, in Sioux City, Iowa. The son of Pluma Irene Edwards, a musician and William Albert Deming, a mathematician and man of law. W. Edwards Deming was encouraged to succeed in his studies from a very young age.

Deming attended the University of Wyoming where he graduated with a Bachelor of Science in electrical engineering in 1921. From there he attended graduate school at the University of Colorado and graduated in 1925 with a master’s in mathematics and physics. Edwards Deming finished out his graduate school experience at Yale University in 1928 with a PhD in mathematics and physics as well.

While attending graduate school at Yale, Deming worked as an intern at Western Electric’s Hawthorn Works in Cicero, Illinois. Later after he graduated from school, Deming worked in the census department of the United States department of agriculture under Gen. Douglas MacArthur. During that time, he was also working as a census consultant for the Japanese government.

Consequently, this is where he became involved with the Union of Japanese Scientists and Engineers, also known as JUSE. Shortly after teaching a seminar on statistical process control, Deming was invited to talk with Japanese business leaders on Deming’s own theories on modern methods of management practices. After this, his lifelong career in statistical quality control and modern methods of industrial management commenced.

Why is Deming Known as the Father of Quality Control?

Graduating with a PhD in mathematical physics, naturally Deming was introduced to statistics. However, it was quite unconventional when he applied his new skills to manufacturing management techniques. Deming used statistical methods to quantify any type of manufacturing process. Melding these concepts together was all about how efficient the company was, the quality of their products, and then related both of those theories to how the company was managed.

Known as the father of quality control, Deming’s principal theory dealt with the reason why manufacturing operations were flawed. In short, management was to blame. To go with his simple idea of ensuring quality before the product was created, Deming reasoned that the only way operations could be improved was if management was taking immediate action to do so, instead of pinning improvement solely on employees.

From this new philosophy for specialized quality control techniques blossomed the J apanese industry post World War II, as western management practices in the U.S. lagged behind.

The Relationship Between Variation and Quality

Deming believed that to achieve a reliable and predictable output, one must understand the different types of variation in a process. Understanding inherent variation is essential for running a successful Total Quality Management, or TQM program.

There are a total of four different types of variation in a process:

- Common cause variations – These are inherent to all systems. For example, therefore regular maintenance such as oil changes and tire changes are necessary on a vehicle.

- Special cause variations – These are unusual circumstances, usually caused by human error.

- Tampering – Unfortunately when there are attempts made at trying to fix variation, only more variation is a result. Note that tampering is often due to the best intentions.

- Structural variation – This is when no two parts are the same in part of a process.

How do we fix variation when tampering leads to even more variation? The key is monitoring. Deming realized that trends should be looked at as they build over time, not every single variation should be “taken care of” in the moment. In fact, it was much better to study the process before making such a large decision.

He established this by, of course, using a statistical experiment referred to as the funnel experiment. You can find information about the funnel experiment here.

Deming’s Contributions to Lean Manufacturing

Following Lean manufacturing methods such as 5S can be done but gathering an understanding on the philosophy of management plays a huge role on whether or not leaders can achieve what they set out to do within a Lean system. That’s where the Deming teachings come into play.

The statistical methods that Deming contributed to modern methods of Lean manufacturing included the PDSA cycle, the 14 points of management, and the 7 deadly diseases of management. Each of these systems promote a vigorous program centered quality control as well as continuous improvement in the workplace.

It must be remembered, however, that Deming's statistical methods work on a different level than that of Lean manufacturing. While they share similarities, they still rely on differing techniques to achieve efficiency, improvement, and an increase in productivity.

The Deming Wheel

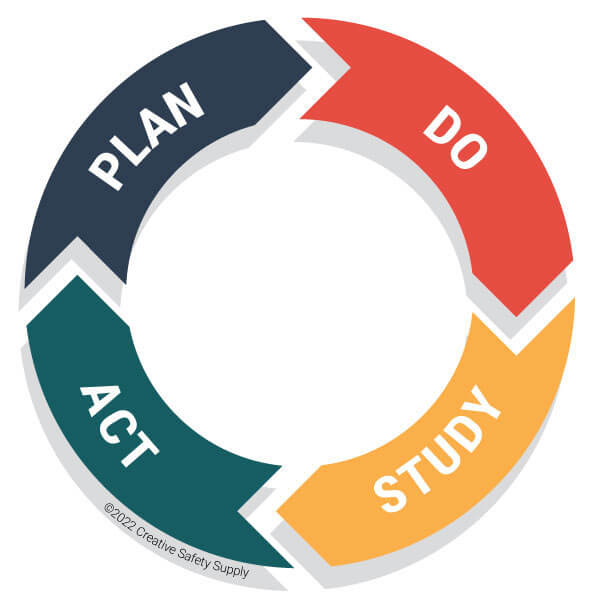

Often called the PDSA Cycle or the Shewhart Cycle, the Deming Cycle is an exceptionally simple model for improvement. Deming learned this technique from his colleague Dr. Walter Shewhart and made an effort to popularize the method.

There are four parts to this method, they are as follows:

- Plan – Those implementing the change must have a plan for how to complete the change as well as how to collect any necessary data. What is the objective? What will happen and why? How will the change be tested?

- Do – Try the new method out on a smaller scale. What were the problems? Analyze any data gathered.

- Study – Study the results! How does it compare to the predictions made in the Plan step? How would you summarize the test? What have you learned?

- Act – Based on what was learned from the test, now is the time for refinement. What modifications should be made? Loop back around to prepare planning for the next test if needed.

You may be familiar with PDCA which stands for Plan, Do Check, Act. However, Deming realized that this method relied on determining the success or failure of an implemented change. By replacing “Check” with “Study,” Deming was able to focus on studying the actual results of the new quality control method to see if any revisions were needed or if any new knowledge was needed to make a better change.

Both PDCA and PDSA are excellent tools to be used alongside Lean management practices and as a Total Quality Management problem-solving tool.

Deming’s 14 Points for Management

Deming conceptualized the 14 points of management upon writing his book titled Out of the Crisis. These points reflected the necessary obligations that management were to follow to construct a workplace that was immersed in improvement as well as invested in long-term business goals.

It must be noted that Deming dd not intend these 14 points to be a checklist of actions, but rather a philosophical code to follow and embrace within the workplace culture. Not only would this effect the quality of output from companies that successfully implemented this type of culture to the workplace, but it would give them a better understanding of their purpose as individuals as well as a collective whole.

The following is the list of the 14 points for management that W. Edwards Deming developed:

- Create constancy of purpose – This principle is about long-term thinking about the organization as a system. The goal is to take a competitive position, to stay in business, and to provide jobs for workers. Furthermore, this is an attribute that is created to help the organization succeed, not to merely be able to check it off your list as complete.

- Adopt the new philosophy – Management must recognize the challenge, learn their responsibilities, and take on the role of leadership to be successful.

- Cease dependence on inspection to achieve quality – Deming believed it was necessary to eliminate the need for mass inspection. He supported this route of thinking by promoting the act of building quality into the product in the first place rather than performing mass inspection protocol after everything has been completed.

- End the practice of awarding business based on price tag – Put in the simplest of terms, don’t go for the cheaper option just because you save money as that savings may not account for the time wasted on product that fails to last, or isn’t of the best quality. Instead, the Deming management method suggests that the company must minimize total cost. For example, they may move toward a single supplier for any one item, on a long-term relationship of loyalty and trust (as well as quality).

- Improve constantly and forever the system of production and service – This means never ending process improvement and improving the process improvement method itself systematically. With this mentality you will be able to achieve quality and productivity improvements while also constantly decreasing costs.

- Institute training on the job – Not only do new and experienced employees need an understanding on how the organization works, but they also need to be trained on how to seek improvement opportunities according to the Deming philosophy.

- Institute leadership – Deming meant for leadership to create management systems that gave people the ability to take pride in their work. This will help the company provide for the needs of the workers, meet customer demands, and maintain a relationship with stakeholders. Overall, the aim of supervision should be to help people, machines, gadgets to do a better job.

- Drive out fear – Take it this way, if the system incentivizes good looking data for perks such as promotions or bonuses, then the chances of procuring tainted data become higher. Getting rid of fear can help everyone work effectively for the company.

- Break down barriers between departments – People in research, design, sales, and production must work as a team to foresee problems of production.

- Eliminate slogans, exhortations, and targets – Slogans that ask for zero defects and higher levels of productivity do nothing to demonstrate those values. In fact, slogans have the potential to create adversarial relationships between management and employees since low quality and low productivity belong to the system, not people.

- a. Eliminate work quotas on the factory floor – Instead, substitute leadership.

b. Eliminate management by objective – Eliminate management numerical goals. Instead, substitute leadership. - a. Remove barriers that rob the hourly worker of his right to pride of workmanship – The responsibility of supervisors must be changed from quantity to quality.

b. Remove barriers that rob people in management and in engineering of their right to pride of workmanship – This means the abolishment of the annual or merit rating and of management by objective. - Institute a vigorous program of education and self-improvement – This will only help to improve continual improvement.

- Put everybody in the company to work to accomplish the transformation – Everyone must participate for it to be successful.

There is no picking and choosing which of these principles you can implement at your facility. Each one of them must be used together to get the desired results. In fact, Dr. Deming ties these concepts together in what he calls The System of Profound Knowledge or SoPK. It ties together his teachings of quality, management, and leadership into four areas:

- The appreciation for a system

- Knowledge of variation

- Theory of knowledge

- Psychology

The 7 Deadly Diseases of Management

W. Edwards Deming has defined the 7 barriers that management will likely face while following his philosophy of the 14 points to succeed in transforming the workplace into one that has a better level of understanding in continual improvement for processes.

Those deadly diseases are as follows:

- A lack of constancy of purpose – This will result in a company that cannot plan production or services that will have a market and keep the company in business as well as provide more jobs.

- Emphasis on short-term profits – Known also as short-term thinking, this mindset is fed by the fear of unfriendly takeover as well as a push from bankers and owners for higher dividends.

- Evaluation of performance – Taking the form of merit rating or in annual reviews, the evaluation of an employee’s performance is often measured in matters of quantity rather than that of quality such as interaction with other employees and value of work performed. Measuring in quantity doesn’t follow Deming’s philosophy of continual improvement.

- Mobility of management – Also known as job hopping, the mobility of management alludes to the perpetual belief of short-term thinking. Short-term thinking damages organizations, as we’ve mentioned in the second point above.

- Management by use only of visible figures – There will always be instances where decision making cannot be supported with data, yet it still must be managed.

- Excessive medical costs – Executives shared with Deming that the cost of medical care for their employees was amongst their largest overall expenses, not to mention the cost of medical care embedded in the purchase price of what they purchased from their suppliers.

- Excessive costs of liability – This is caused by the lawyers that companies employ who work on a basis of contingency fees.

Deming does note that these are particularly unique to industry in the United States. By being aware of these challenges that you may face in the workplace you can avoid or appropriately address them with the use of Deming’s 14 points of management.

Deming’s Impact Globally

Because of Deming’s extensive work involving Japan’s economic recovery after World War II, the Prime Minister of Japan awarded Deming its highest honor for a non-citizen: the Order of the Sacred Treasure, Second Class.On top of being so influential in Japan as well as his methods becoming more popular in America after his death, Deming had one of the highest awards for TQM attributed to him in 1951 called the Deming Prize. AS one of the longest-running prizes for TQM, the Deming Prize is awarded to both individuals as well as businesses who have successfully implemented a Total Quality Management program.

All in all, Deming was quite the contributor to quality management theory during his life and well after his death.

Additional William Edwards Deming facts:

- W. Edwards Deming was an American statistician, professor, author, lecturer, and consultant who is widely regarded as the father of quality management. He created the new quality-control methods and developed the sampling techniques for U.S. Census. He was also influential in the post-WWII economic recovery of Japan. Source: https://en.wikipedia.org/wiki/W._Edwards_Deming

- Deming received a BS degree in electrical engineering from the University of Wyoming, an MS degree from the University of Colorado, and a PhD in mathematical physics from Yale University. He also had an internship at Western Electric’s Hawthorne Works in Cicero, Illinois, while studying at Yale. Source: https://www.britannica.com/biography/W-Edwards-Deming

- Deming is best known for his 14 points for management, which are a set of principles for transforming business effectiveness and quality. He also developed the Plan-Do-Study-Act (PDSA) cycle, which is a four-step method for continuous improvement of processes and products. Source: https://www.wikiwand.com/en/W._Edwards_Deming

- Deming was awarded the Order of the Sacred Treasure, Second Class, by the Emperor of Japan in 1960, for his contributions to Japan’s industrial development. He also received the National Medal of Technology from President Ronald Reagan in 1987, and the Distinguished Career in Science award from the National Academy of Sciences in 1993. Source: https://www.thefamouspeople.com/profiles/william-edwards-deming-3140.php

Similar Articles

- An In-Depth History of the Kaizen PDCA Cycle

- A Brief History of Kaizen: The Key Players

- Quality Management Systems (ISO 9001:2015)

- Peter Drucker: The Founder of Modern Management Studies

- The Development of Scientific Management by Frederick Taylor

- Quality, Health, Safety, Environment (QHSE) Management Systems

- Quality Control

- What is Toyota Lean Management?

- Quality Circle