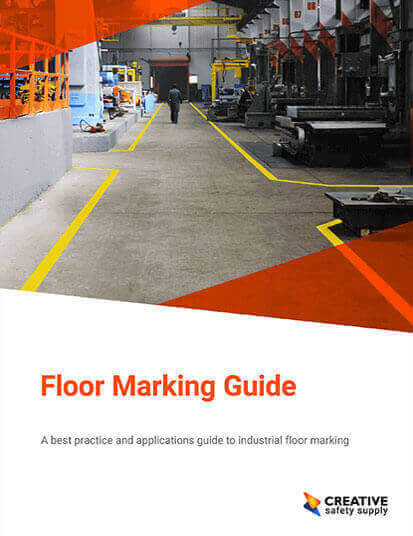

Experience a smoother workflow and enhance workplace safety by effectively implementing floor markings. These act as visual signals, providing more information about the area they are added into so the movement of both products and people is managed with ease.

Applying floor marking can be done in various ways but many business owners opt for floor marking tape as it is a quick and low-cost way to put instructions in place. In comparison to painting floors which require stenciling and a tough paint that does not rub off when faced with constant traffic, tape provides an instant result that can be removed if needed.

The versatility of floor markings means they are commonplace across various industries, being effective in buildings ranging from supermarkets to industrial warehouses. Whether they are in place to direct customers through a pathway or instruct heavy goods vehicles which way to drive through a site, these markings can significantly enhance safety measures and improve operations daily.

When Floor Markings Should Be Used

Although floor markings are most commonly used in larger settings, they can also prove particularly effective in smaller businesses that have complex site layouts. Many organizations benefit from the use of floor markings and although safety is often a key factor in deciding to implement them, it can also offer a range of additional benefits in other areas of the business, being used for reasons such as;

- To highlight the area which should be used for loading and unloading

- Mark any walkways and pedestrian areas

- Control the movement of vehicles through a site

- Specifying the areas in which products should be stored within a warehouse

- To make it apparent where hazards lie

- To guide visitors around a site and provide direction

- Helping employees locate the equipment or areas they need

Understanding The Colors Used For Floor Marking

The different floor tapes available follow a standardized set of color standards which means they can be understood by both visitors and employees within the industry. Although the system does not have to be followed and a business can choose its definitions if preferred, the standardized colors make it easy for everyone to follow the instructions without confusion.

Yellow Tape

Being one of the most common colors used for floor markings, yellow represents the movement of traffic which can apply to both foot or vehicle motion. Whether it is used in aisles to direct customers or in the outside areas to direct vehicles, yellow markings are easy to spot and can be recognized in an instant.

White Tape

White tape is used to pinpoint an area used to store equipment or products. Whether it is equipment that is hired out across departments, carts that need to be returned at the end of each day, or even small tools which can easily get misplaced, using white tape to outline their storage space means people are aware of their presence, not only know where to find them but where to return them to after use.

Blue, Green, or Black Tape

Although many businesses use different colors for different purposes, they are used for similar uses on a standardized scale since they are too similar in shade. In most cases, the blue, green, or black tape will be used to identify completed goods or those that are in the process of being completed. Especially in darker areas, the colors can be tricky to tell apart unless close up, so use these with caution when establishing the meanings of your floor markings.

Orange Tape

Orange tape is not one of the most common options but can prove particularly useful in industries where there is a constant cycle of inspections being carried out for either product output or equipment checks. Orange tape can be used to separate the goods which are being kept separate for inspection, avoiding mix-ups or hold-ups.

Red Tape

With red being widely understood as a color signifying hazard, red tape is an effective choice for separating goods that are not fit for purpose. Whether that be faulty equipment, waste ready for disposal, or goods which are needing to be kept away from the rest, red tape can be used to cordon off certain items.

Red and White Tape

Referring to areas that need to be kept clear, red and white tape is easy to see and its meaning is obvious to passers-by. Often used for safety reasons, red and white tape can be placed around access to medical equipment, fire extinguishers, or emergency exits to ensure they are kept clear from blockages at all times.

Black and White Tape

Similarly to red and white tape, black and white tape is also used to keep areas clear but does not apply to emergencies. Uses may include workspaces that should be kept clear of equipment and waste or areas which are used for storage, avoiding clutter and disruption in the workplace.

Black and Yellow Tape

Being easy to spot from a distance, black and yellow tape is perfect for highlighting hazards. Whether it be a risk of injury posed by potentially dangerous equipment or hazards in a walkway, the use of black and yellow tape instantly draws attention to the area.

Applying Floor Markings Effectively

For long-lasting results and a professional finish, applying floor marking tape correctly will guarantee maximum efficiency.

- Determine the areas which you wish to section off and clear them of any obstructions.

- Thoroughly clean the floor to remove any dust, oil, or debris that can prevent the tape from binding with the floor.

- Carefully measure the width of the area and mark the perimeter if necessary.

- Determine the suitable color for the floor marking based on the meaning which has been defined within the organization.

- Load the applicator with the correct floor marking tape and apply it carefully to the area.

- Use a damp mop to clean the area once ready.

Similar How-To's

- How to use Pipe Markings with the Proper Color Codes

- How to Use a LabelTac Industrial Label Printer

- How to Implement Pipe Markings

- How to Mark your Floors for Enhanced Warehouse Layout

- How to Use a Pull System

- How to Install SafetyTac

- How to Use GHS Labels

- How to Encourage PPE Use

- How to use Six Sigma in your industry