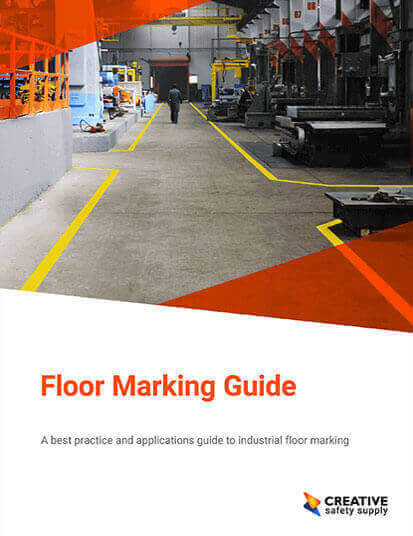

Factory environments have a lot going on, whether that be forklifts carrying raw materials and finished items, or workers participating in manufacturing tasks. Unfortunately, busy environments make for dangerous ones if the facility is disorganized. Keeping everything running smoothly is very important!

One of the best ways to improve safety, organization, and efficiency in a factory setting is to use special floor markings. These markings are a low-cost option that provide a significant number of benefits for both the facility and its employees.

Understanding how floor markings are used, and how to get the most benefit out of them, is important for any facility. In many cases, factories will have a safety manager work with department leadership teams to come up with an effective floor marking strategy. Since floor markings can last for many years without needing to be replaced, it makes sense to put in the time and effort needed to get everything set up correctly.

The Different Floor Marking Options for Factories

There is no “one size fits all” type of industrial floor marking. The assembly line may need different markings than storage areas, or perhaps the forklift drivers need special vinyl tape to manage forklift traffic. Each facility that chooses to improve their visual communication has their own unique needs. That being said, when choosing floor markings for a factory, there are quite a few options to be aware of.

Different floor markings can be used for different applications, and in some situations, it may be necessary to use more than just one type! You might want to pair floor marking tape with floor signs, or perhaps you would like to incorporate some floor marking shapes for an extra safety measure. Let’s dive into the different options you have for improving your factory site.

Floor Marking Tape

Floor marking tape is one of the most popular options because it is inexpensive, easy to apply, and long lasting. When applied correctly, floor marking tape can last for years without any issues. In high-traffic areas, or areas where heavy machinery is used, there are heavy duty products available that can ensure it won't peel up or snag on passing equipment.

Floor marking tape comes in several different colors and widths. Not only that, but it can also have patterns or text printed right on the tape to help convey clear messages.

Considering its durability and wide variety of options, many facilities including factories opt for this material because it saves them time, money, and effort in the long-term scale of facility improvement.

Floor Marking Paint

Floor marking paint is another option to consider, and it can be very effective in some situations. However, painting floors does take more work. Not only that, but in many environments paint application may require the facility to shut down during its application due to fumes and the resulting wet paint.

One advantage of floor marking paint is that it can be easily applied in different patterns to convey specific messages. For example, using stencils to make letters is a common way to benefit from floor marking paint. Paint can also be used in outdoor areas where there is a lot of rain or other elements that could impact tape, though there are types of tape made for these environments as well.

Floor Marking Signs

Floor marking signs are a very popular option for conveying specific information. Imagine a sign that you may normally see tacked to the wall or posted on a metal stake, then change the material to a strong vinyl and add adhesive to the backside.

Floor Marking Shapes

Floor marking shapes are often lumped into the same category as floor marking tape. These nifty adhesive visual tools can take the form of footprints to indicate where people should travel, arrows to give direction, or any number of other shapes.

These visual tools are especially effective at directing workers along certain pathways and aisles. Showing them exactly where to go improves both the traffic within the facility as well as safety. That being said, efficiency is gained when floor marking shapes are used.

Apply Floor Marking Tape for Facility Improvement

Adding floor markings to a facility provides three outstanding advantages that make it a very cost-effective option. That includes:

- Enhanced organization

- Improved safety

- Increased efficiency

These three benefits go beyond just complying OSHA regulations or other regulatory agencies to avoid citation. Placing floor marking tape in your facility speaks to the inherent need to improve the workplace in terms of worker safety as well as moving to a new level of success in terms of output. Let’s dive a little deeper into what facility improvement entails.

Floor Tape for Organization

Floor markings can help to dramatically improve the organization of any factory. A company can use markings to identify where mechanical equipment should be stored when not in use, establish a visible boundary for hazardous work areas, denote the location of fire extinguishers or emergency eye wash stations, and much more.

An organized workspace is the first step for improvement. If you are familiar with 5S and Lean manufacturing, then you know that the space must be decluttered to see any safety issues hiding in the area. Now that goes for any type of environment whether it be an office, or the environment we’re going over today: factories.

Floor Tape for Safety

One of the most significant advantages of using floor markings in a factory is the improved aspect of safety. Implementing floor markings can help:

- Direct employees to emergency equipment

- Reduce forklift collisions in traffic lanes

- Decrease physical hazards

The list could go on and on! The point is that the highly visible floor tape and floor signs that began as an organizational tactic, transformed the workplace into one that eliminated or reduced several different physical hazards. Facility marking is a tremendous tool, maybe we can convince you further with the last benefit it provides, that being efficiency.

Floor Tape for Efficiency

Safety and organization working together equates to a more efficient workplace. While workers can avoid serious injuries on the job thanks to the nicely organized forklift parking spots, traffic lanes, and clearly marked work cells, they are also getting more done during the day.

By relieving the area of any safety hazards, you’re actively preventing any lost time that would have occurred with an injury. That is instead replaced with productivity. Who would have thought such a simple task of organization, coupled with visual communication, would help out factory settings so much!

Industry Standards for Floor Marking

There are many reasons why factories use floor markings in their facilities, but in many cases, it isn't an optional decision. OSHA and other standard setting bodies such as ANSI and the NFPA are the entities that make floor marking a best practice method, therefore the industry standard.

While the markings themselves are in most cases mandatory, facilities do typically choose how they implement them. As has been mentioned already, companies can use floor marking tape, floor marking paint, or any number of other options pertaining to lean manufacturing products. The following sections are a handful of notable industry best practice methods, as well as OSHA regulations to be familiar with when implementing floor tape at your factory site.

Visual Safety Requirements from OSHA

OSHA creates the standard to follow for floor marking requirements. This entity often takes standards created by other standard setting organizations such as ANSI and the NFPA and makes them mandatory, even though the original was technically voluntary. While many people outside of the safety world may think this is unfair, and unfortunately some within the realm of safety as well, it is in the best interests of all those working in the facility. These regulations help to keep people out of the hospital for injuries and allows workers to go safely home to their families every day.

Let’s go over some of the most recognized regulations that OSHA has released about floor marking requirements.

1910.176(a) specifically states, “Use of mechanical equipment. Where mechanical handling equipment is used, sufficient safe clearances shall be allowed for aisles, at loading docks, through doorways and wherever turns or passage must be made. Aisles and passageways shall be kept clear and in good repair, with no obstruction across or in aisles that could create a hazard. Permanent aisles and passageways shall be appropriately marked.”

1910.144(a)(1): “Red shall be the basic color for the identification of fire protection equipment and apparatus…danger…emergency stopping.”

1910.144(a)(3): “Yellow. Yellow shall be the basic color for designating caution and for marking physical hazards such as: Striking against, stumbling, falling, tripping, and ‘caught in between.’”

1910.35: “OSHA will deem an employer demonstrating compliance with the exit-route provisions of NFPA 101, Life Safety Code, 2009 edition, or the exit-route provisions of the International Fire Code, 2009 edition, to be in compliance with the corresponding requirements in §§ 1910.34, 1910.36, and 1910.37 (incorporated by reference, see section § 1910.6).”

Please make sure the person who is facilitating the floor marking project becomes familiar with all these standards. Doing plenty of research beforehand will not only make the task easier, but it will end up being correct on the first try.

Standard Sizes for Floor Marking Tape

There is also a best practice method for the width of any floor marking tape placed in facilities such as factories. Unfortunately, OSHA just states that aisles and passageways must be “appropriately marked” without giving the reader any details on what “appropriate” entails.

The generally accepted best practice method is to have 2-6 inches of width for the floor marking as well as a minimum of 3 feet wider than the width of the largest piece of equipment using that aisleway or 4 feet, whichever is most practical.

Color Requirements for Floor Markings

Technically speaking, OSHA does not have any strict requirements on the colors used for floor markings. They do give some guidance in this area, and these types of guidelines may become requirements in the future. OSHA's 29 CFR 1910.144 regulation for safety color codes is one of the best places to start for determining what colors to use when marking floors.

By following these guidelines, factories are not only going to be ready for any future requirements from OSHA, but they will also be following a standard that is used by most facilities. This will help improve safety by making sure employees know what colors mean regardless of where they are working.

Many safety experts also use the ANSI Z535.1 Safety Color Code Standard. This is an excellent reference for utilizing floor marking. ANSI’s Safety Color Code Standard includes color specifications that will never steer you wrong in terms of OSHA compliance. In fact, most factories today will take advantage of additional floor marking opportunities beyond what is officially required.

Why should Industrial Floor Marking be Used?

Industrial floor marking tape should absolutely be used to improve facility safety, organization, and efficiency. Not only that, but floor tape and signs can only positively affect your workplace. Employees will benefit from any extra information about hazards and emergency response.

Plus, visual markings like floor tape are meant to last for years without replacement. That means less time spent maintaining floor tape for permanent aisles, storage areas, and any other hazardous places you can think of. Less maintenance also means saving money on both time and floor tape material.

So again, the benefits of saving time, costs, and injury prevention are all worthy reasons as to why floor tape is a necessity in environments like factories.

Maintaining Visual Safety in Factories

Now, while there is less maintenance with industrial floor marking tape, factory environments can be very harsh, especially on the floors. That being said, there may be occasional maintenance involved with industrial floor marking tape. People walk through the area, vehicles drive through the area, heavy objects are dragged over the floors, and much more. Floor markings need to be properly maintained in order to ensure they last for a long time.

Fortunately, floor markings are made to be durable, and can be cleaned and maintained using most normal products. Maintenance teams can wash the floors to keep these markings clean and visible. If the tape or paint starts peeling up, they can often be pressed back into place. Should the damage become extensive, it can be pulled up in the area and replaced quickly, easily, and affordably.

Floor Marking Resources from Creative Safety Supply

As the leaders in visual safety, we are the Lean experts you can trust. Creative Safety Supply has countless resources when it comes to floor marking, one of our specialties. Brush up on standards and regulations with our numerous educational resources about floor marking here. We also have a free downloadable OSHA Floor Marking Guide that you can use as a reference for your new floor marking project.

To finish off, we also make our very own industrial floor marking tape! SafetyTac®is one of the most durable floor marking options on the market. With our tape, you’ll be able to create a tidy workplace that keeps workers informed of their surroundings. You can also check out our other floor marking options here. You’ll find floor signs, shapes, and even glow-in-the-dark floor tape.

Similar Articles

- Types of Floor Marking

- OSHA Floor Marking

- Floor Marking for Facility Safety

- Floor Marking for Fire Extinguishers

- Floor Marking Ideas for Warehouses

- Floor marking comprehensive research, education and training

- Industrial Floor Marking Guidelines

- Visual Factories

- Aisle Marking Tape – 5 Strongest Tapes You have Ever Seen!