Muda is a Japanese term for waste that, in the context of lean manufacturing, refers to activities, processes, or resources that consume resources without adding value to the customer. These activities are considered waste and are targeted for elimination or reduction to improve efficiency and productivity. Essentially, Muda encompasses anything that consumes resources without contributing to the final product or service that the customer is willing to pay for.

The concept of Muda, developed by Taiichi Ohno of Toyota, identifies seven primary types of waste, including:

Transportation: Unnecessary movement of products. Products are more likely to become damaged or lost during transportation and if it is not necessary, will not add any value to the product or for the customer.

Transportation: Unnecessary movement of products. Products are more likely to become damaged or lost during transportation and if it is not necessary, will not add any value to the product or for the customer.- Inventory: Inventory includes raw materials, WIP, and finished goods. The longer a product sits in one of these states, the more wasteful it is. It disrupts the workflow while not adding value for the facility, leads to longer lead times, and can result in damaged or defected products.

- Motion: This is not the motion of the product, but rather the unnecessary movements of workers that are wasteful or harmful. This may lead to strain injuries for workers, downtime, or equipment breaking down due to wear and tear.

- Waiting: A product not currently being processed or not in transport is considered to be “in waiting.” When it sits waiting, the workflow is interrupted and the value of the product decreases.

- Overproduction: Producing more than what is required is one of the worst kinds of waste. It can hide defects in products while taking up important storage space and making it more difficult to manage.

- Over-Processing: Offering a product or service that exceeds the requirements of a customer can be seen as over-processing. It takes longer and requires more money than required, making it wasteful.

- Defects: Products that do not meet company standards (defective) will likely need to be reworked or scrapped, wasting the resources that have already been used thus far. It adds cost to operation but does not add value for the customer.

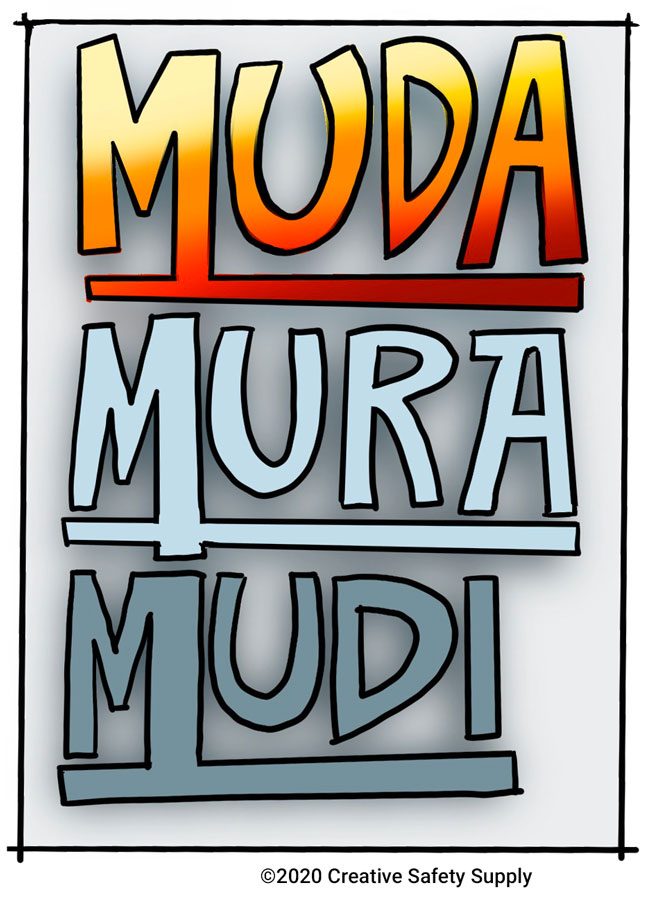

Muda is frequently used together with Mura and Muri in the context of lean manufacturing and the Toyota Production System (TPS), representing three types of waste or inefficiencies that organizations aim to identify and eliminate to improve their processes.

Similar Questions

- What is 3M in manufacturing?

- What is the goal of Lean?

- What are the 7 (or 8) wastes of Lean manufacturing?

- Is mass production considered Lean?

- How can Lean affect the supply chain?

- What is Lean manufacturing?

- What do the letters in the acronym DOWNTIME refer to in Lean Methodology?

- What is just-in-time (JIT) manufacturing?

- What does Lean Manufacturing consist of?