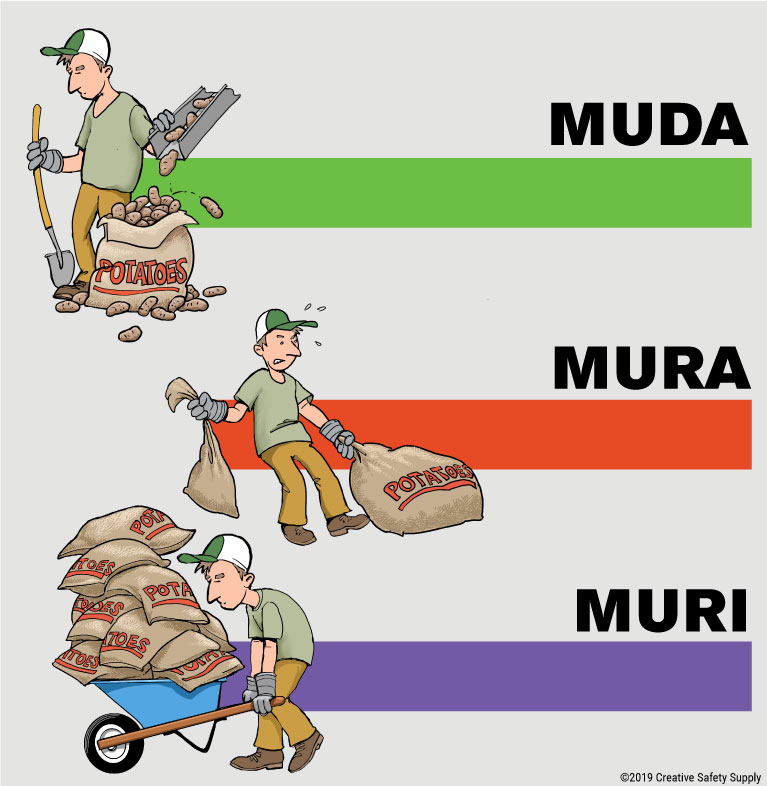

Muda, Mura, and Muri are Japanese terms that refer to the three broad categories of waste found in a business. Understanding how each of these wastes impacts a facility is key to implementing a successful Lean manufacturing process.

Muda

Literally translated, Muda means “futility; uselessness; wastefulness,” though more broadly, it refers to the seven common types of waste seen in business operations. These seven wastes include the following:

Literally translated, Muda means “futility; uselessness; wastefulness,” though more broadly, it refers to the seven common types of waste seen in business operations. These seven wastes include the following:

- Defects occurring in the final product

- Waiting for the next step in production to occur

- Excess motion of people and equipment than is needed

- Excess inventory that is sitting and taking up space

- Overproduction meaning that the manufacturing process is ahead of public demand

- Overprocessing without creating value

- Unnecessary transport or handling of materials

There are two types of Muda that facilities must be aware of while performing manufacturing processes. The first is waste that is non-value adding but essential for the satisfaction of the customer. The other is non-value adding and is also unnecessary for customer satisfaction.

The latter form of Muda is what contributes to the above wastes as well as any hidden costs within the process. This is the form of waste that must be eliminated.

Mura

Mura refers to “unevenness” or “irregularity,” specifically irregularity in production levels. Consistently stable levels of production allow a business to effectively implement maintenance procedures and reduce worker fatigue, while uneven production leads to more frequent equipment failures, employee burnout, and increased difficulty in accurately planning.

Devising a way to prevent Mura in the workplace could begin with establishing a Just-in-Time production system. Keeping little to no inventory in storage establishes a pull system from the manufacturing process. This means the right parts must be delivered or made at the right time to produce an even workflow for employees while also decreasing the cost of inventory storage, preventing bottlenecks, and increasing efficiency.

To get here, companies may choose to implement Kanban to establish that “pull” effect in the manufacturing process. Heijunka is also an excellent production leveling tactic.

Muri

“Beyond one’s power” is an especially potent definition for muri, as it refers to employees or equipment that have been overburdened. The dangers of muri should be obvious. Employees who are overworked experience greater levels of burnout, and a lack of situational awareness caused by exhaustion can be extremely dangerous, particularly in industries that rely on heavy machinery or dangerous chemicals. Likewise, equipment that’s stressed too much will break down more frequently and can create wholly new hazards for anyone nearby.

Muri could and should be avoided with the establishment of standardized work. Ensuring that all employees know how to complete a task one way is the definition of standardization. In a facility without a standardized workflow, there could be 10 different ways a manufacturing process is completed just because of a lack of communication not only between departments, but also the employees and management themselves.

When standardized, facilities can enjoy higher morale, better quality products, an increase in productivity, and lower facility operation costs due to less waste.

All Lean companies strive to eliminate Muda, Mura, and Muri, but it’s important to explicitly identify all sources of waste before deciding on a removal plan. Muda, Mura, and Muri feed into and directly impact one another, and it’s all too easy to decrease Muda only to see Muri increase. Or for Mura to decrease while Muda increases.

To avoid a painful, drawn-out game of inefficiency whack-a-mole, Muda, Mura, and Muri should be combated simultaneously, using a holistic approach that trades quick, superficial fixes for entrenched improvements in business processes.

Similar Glossary Terms

- 7 Wastes of Manufacturing

- Understanding Lean Manufacturing Terms

- Heijun-ka

- TIMWOOD

- Waste of Overproduction

- Lean Production

- DOWNTIME

- Lead Time

- Capability