Resources

Facility Marking Articles

OSHA Floor Marking Requirements You Should Know

Figuring out OSHA floor marking guidelines can be puzzling without hours of research. To help you save time and get back to what’s important, we’ve compiled a guide on OSHA floor marking that focuses on the key objectives and ensures compliance. …

Maintain the Durability of Your Floor Tape

Find the best tips and tricks for making the most of your floor tape (and money) despite the heavy foot traffic. …

A Guide to Workplace Safety Signs

Workplace safety programs have many parts, all of which are important to keeping people safe on the job. Safety signs play a key role in many aspects of safety from notifying people of tripping hazards and PPE requirements to explaining arc flash and chemical hazards. …

Ammonia Pipe Marking Standards | IIAR Requirements

Because ammonia is harmful to human health any pipes carrying ammonia-based substances must have more specific labeling than those under the ANSI/ASME standards. …

Marine Pipe Marking | ISO/DIS 14726

Since marine environments are required to carry fresh water along with gases, waste media, and fire-fighting chemicals, sea-faring vessels must comply with additional pipe marking color codes. This extra effort put into pipe markings for sea-faring vessels provides workers and first responders with the information they need regarding the unique contents of those pipes. …

Medical Substance Pipe Marking | NFPA99/CGA C-9

Substances used for medical purposes have their own standards and best practices as well. Since chemical substances used in hospitals are primarily gases, which are highly flammable, the National Fire Prevention Association (NFPA) is the entity that regulates and sets safety standards. …

Water Treatment Pipe Marking

In water treatment facilities, proper pipe marking is essential for maintaining safety, efficiency, and regulatory compliance …

5 Lean Manufacturing Tools that Work

These five lean manufacturing tools are essential for making your lean journey a success. …

Labeling Practices for Power Generation Facilities

The power generation sector faces distinctive challenges, with hazards ranging from electrocution to arc flashes. Despite these risks, it remains one of the safer sectors due to stringent safety measures and regulations. Power facilities also incorporate redundancies to prevent outages, emphasizing the need for clear communication through labels, signs, and visual tools. …

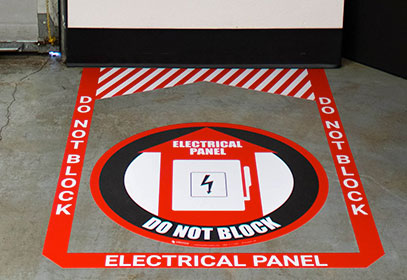

Floor Marking for Electrical Panel Compliance

Meet OSHA requirements for electrical panel clearance with floor markings! Creative Safety Supply offers a wide selection of floor signs and floor tapes for breaker panels. …

Quality, Health, Safety, Environment (QHSE) Management Systems

Quality, Health, Safety, Environment (QHSE) management systems help businesses achieve three main objectives: enhanced quality, worker safety, and environmental sustainability. …

Automated Guided Vehicle Lane Marking

AGVs exist in large facilities to help with consistency and safety. Used for manual labor, AGVs are able to reduce steps in processing to focus on other priorities. …

A Quick Guide to Underground Utility Labeling

Underground utility labeling is an essential ingredient to every project that involves construction. This article outlines the step-by-step process of getting your site inspected for utilities, and how to label underground lines safely and accurately. …

Your Guide to Pipe Labeling Standards

If you are looking to implement or update a pipe marking strategy for your facility it is important to gathering as much information as possible. Read More... …

Electrical Wire Colors

Electrical wire colors are essential to the safety of anyone working with electricity. Click here and learn more about electrical color standards. …

A Guide to Pipe Marking Standards

For most industries, abiding by ASME/ANSI pipe marking standards is sufficient for staying safe and OSHA compliant. Some workplaces, though, are required to comply to more unique pipe marking standards due to the nature of the substance the pipes contain. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

ANSI TIA 606-B Cable Labeling Standards

ANSI TIA 606-B Cable Labeling Standards are a unified labeling method for the wires used in computer systems. These standards help businesses record data and keep their IT environments organized. Get to know these standards; they’ll help your business run more efficiently. …

Waste Water Treatment Labeling

Waste water treatment labeling ensures that all water and flow is accurately labeled. keeping employees safe from contaminated water. …

Floor Marking for Factories

Factories are busy, active environments with a lot happening at all times. Floor marking is a low-cost way of improving efficiency, safety, and organization. …

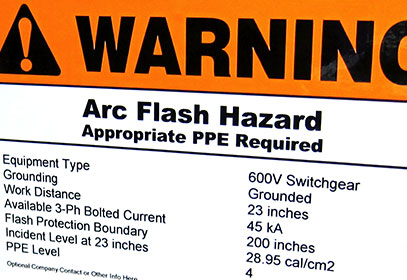

Arc Flash Labeling (Updated)

Arc Flashes are one of the most dangerous accidents that can happen in a facility. Learn how to keep your facility safe and incident-free through proper labeling. …

Floor Marking for Facility Safety

The best way to enhance safety is keeping workers informed, and floor markings are the most reliable, durable method of ensuring that everyone is aware of potential hazards. …

Anhydrous Ammonia – Safety & Labeling

Concentrated (or anhydrous) ammonia presents significant hazards to people and the environment. Here’s what you need to know to stay safe. …

Floor Marking for Door Openings

Every time a door opens, it presents a potential hazard to anyone on the opposite side. With careful floor marking, you can massively reduce this risk and prevent numerous injuries. …

Industrial Floor Marking Guidelines

OSHA doesn’t offer much guidance on how floor markings should be installed, so we’ve compiled some helpful tips and best practices to ensure your markings are useful, straightforward, and helpful to everyone in your facility. …

Floor Marking For 5S

Inexpensive yet endlessly practical floor markings can drastically simplify your 5S efforts, while saving you time and money. Learn more in our latest article. …

Electrical Wiring (Wire Color Codes)

Proper electrical wiring is not the place for uncertainity. Fortunately, Wire Color Codes exist to protect you from harm, while ensuring that the lights stay on. …

Floor Marking for Fire Extinguishers

Use floor markings to make sure you can find the fire extinguisher and that it is not blocked in an emergency. …

Pipeline Labeling

Pipeline labeling is essential when using pipelines in the facility. Without the proper labeling, you are putting your employees at risk. …

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace. …

Warehouse Management

Proper warehouse management can dramatically improve both efficiency and safety. This article covers everything you need to know. …

Visual Factories

Visual factories use signs, posters, charts, labels and floor marking to provide information that improves efficiency, safety and productivity in the workplace. This is a fairly simple concept that yields excellent results. …

Ammonia Refrigeration

When using ammonia refrigeration, or ammonia for anything in the workplace, there are a variety of OSHA regulations that need to be followed. …

ANSI Color Codes for Pipe Marking

When following the ANSI A13.1 standards, the most important thing is to understand the six most common color schemes. …

How to Implement 5S in an Organization

It takes significant effort to implement a proper 5S program, but following the right steps will drive success and help the process go smoothly. …

Floor Markings for Forklift Safety

Installing floor markings for forklift traffic can help improve safety and efficiency in warehouses and factories. Take these steps to keep employees safe. …

Floor Marking Ideas for Warehouses

Warehouse floors provide an opportunity for visual communication. Find out what floor signs, tapes, and shapes you can use. …

Labeling Electrical Conduits

Learn how to label electrical conduits so employees can quickly identify them. …

Types of Floor Marking

Many options exist for marking floors. Learn about floor tapes, virtual floors signs, and more. …

Arc Flash and Electrical Safety

Learn how arc flash works and how it relates to your larger electrical safety program. …

Safety Colors (OSHA Guidelines and Color Codes)

Using colors strategically makes communication in your facility more effective. Get the details about common color codes. …

Lean Supplies

Learn what supplies and tools you can use to make Lean manufacturing efforts successful. …

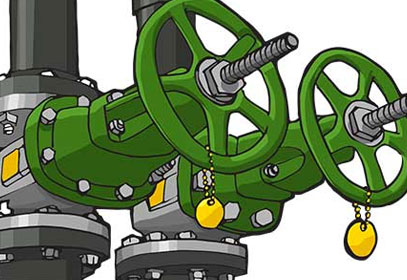

Valve Tags: Guide for Pipe Identification

Tips and recommendations for labeling the valves on your pipe system. …

Aisle Marking Tape – 5 Strongest Tapes You have Ever Seen!

Learn the requirements for marking aisles and the best methods for doing so. …

Pipe Color Codes - ANSI/ASME A13.1

The ANSI/ASME A13.1 pipe marking color code explained. …

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it. …

OSHA Floor Marking

Find out what OSHA has to say about marking your facility's floors. …

Cable Management

Properly marking wires can improve organization, facilitate faster maintenance, increase safety, and more. …

The 5S System [Lean Manufacturing Methodology]

One of the most comprehensive pages you will find on 5S. …

Floor marking comprehensive research, education and training

Everything you need to know about marking your facility’s floors. Types of markings, practical tips, and more. …

Facility Marking Questions and Answers

What are the Best Facility Marking Techniques?

Facility marking is a fundamental aspect of creating a safe and organized work environment. However, with various techniques available, selecting the most effective approach can be a critical decision for facility managers. In this article, we will explore some of the best facility marking techniques, providing valuable insights for those looking to enhance safety and… …

What is Facility Marking?

In the realm of workplace safety and organization, facility marking stands as an unsung hero. It plays a pivotal role in ensuring a safe and efficient work environment across various industries. But what exactly is facility marking? In this article, we will delve into the definition, purpose, and key components of facility marking, shedding light… …

What are the best practices for installing and maintaining facility marking products?

Effective facility marking is a cornerstone of a safe and efficient work environment. However, to ensure that facility marking products serve their purpose optimally, proper installation and regular maintenance are crucial. In this article, we will delve into the best practices for installing and maintaining facility marking products, offering valuable insights for facility managers and… …

How does facility marking improve safety awareness and navigation?

In any facility, be it a manufacturing plant, warehouse, hospital, or office space, safety is paramount. Ensuring the well-being of employees and visitors requires a comprehensive approach, and one crucial aspect is facility marking. This often-overlooked tool plays a vital role in enhancing safety awareness and facilitating smooth navigation within a facility. In this article,… …

What are the benefits and best practices of using color-coding for labels and signs in facility marking?

Why is Color-coding Important? Color-coding is a simple but effective way to enhance communication, organization, and safety in any workplace. Color-coding is the use of different colors to convey specific meanings or associations, such as hazards, functions, locations, or instructions. Color-coding can be applied to various types of visual cues, such as labels, signs, floor markings,… …

What are the benefits of floor marking tape for safety and productivity?

Floor and Aisle Marking Floor marking tape is a simple but effective tool that can help you create a safer and more productive work environment. Floor marking tape is a type of adhesive tape that comes in various colors, shapes, and sizes, and can be applied to different surfaces and objects in your workplace to convey… …

How does proper facility marking help create a more safe and visual workplace?

Visual Safety A visual workplace is a work environment where information, instructions, and warnings are communicated through visual cues, such as signs, labels, floor markings, color codes, and symbols. A visual workplace can help improve safety, productivity, quality, and efficiency in any business or manufacturing setting. One of the key elements of a visual workplace is… …

How can I prevent Warehouse Accidents with Facility Marking?

Within an industrial warehouse setting, thorough safety measures are paramount in order to prevent accidents. Facility marking utilizes visual cues which guide both employees and visitors through the facility in a more orderly manner, not only enhancing safety, but also efficiency and productivity. In this article, we discuss some examples of facility markings that can… …

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)

![The 5S System [Lean Manufacturing Methodology]](https://www.creativesafetysupply.com/template/images/custom/resources-page/Articles-5S.jpg)