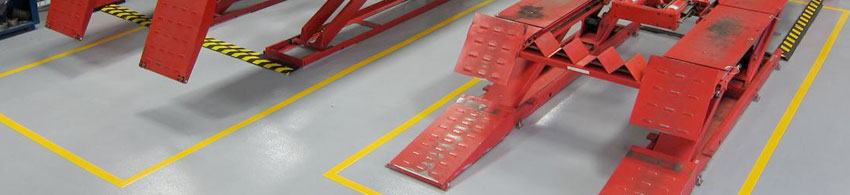

Effective facility marking is a cornerstone of a safe and efficient work environment. However, to ensure that facility marking products serve their purpose optimally, proper installation and regular maintenance are crucial. In this article, we will delve into the best practices for installing and maintaining facility marking products, offering valuable insights for facility managers and safety professionals.

Choosing the Right Materials

- Consider the Environment: Select facility marking products based on the specific environment they will be used in. For instance, outdoor markings may require more durable materials to withstand exposure to the elements.

- Opt for High-Visibility: Choose markings with high-contrast colors and bold, easily recognizable symbols. This ensures that markings remain visible even in low-light conditions or from a distance.

Installation Best Practices

- Thorough Surface Preparation: Before applying any marking products, ensure that the surface is clean, dry, and free from any debris or contaminants. Proper preparation ensures better adhesion and longevity of the markings.

- Use Appropriate Adhesives: Select adhesives or tapes that are compatible with the surface material. For example, some surfaces may require specialized adhesives for optimal adherence.

- Apply Even Pressure: When applying markings, use even pressure to ensure that the product adheres uniformly. This prevents air bubbles or uneven application that could lead to premature wear.

- Follow Manufacturer's Guidelines: Adhere to the installation instructions provided by the manufacturer. This may include specific temperature ranges for application, recommended curing times, and other important considerations.

Maintenance Strategies

- Regular Inspections: Implement a routine inspection schedule to check the condition of facility markings. Look for signs of wear, peeling, or fading, and address any issues promptly.

- Prompt Repairs or Replacement: When signs of wear or damage are identified, take immediate action to repair or replace the marking. This helps prevent potential safety hazards and ensures continued effectiveness.

- Reapply as Needed: Over time, facility markings may wear due to heavy traffic or environmental factors. It's essential to reapply markings as needed to maintain optimal visibility and effectiveness.

Training and Education

- Provide Training to Staff: Educate employees on the importance of facility marking and how to identify and report any issues. This creates a culture of ownership and ensures that everyone plays a role in maintaining a safe work environment.

- Stay Informed about Industry Standards: Keep abreast of any changes or updates in industry standards related to facility marking. Adhering to the latest guidelines ensures that your facility remains compliant and up to date with best practices.

Proper installation and maintenance of facility marking products are essential elements in creating a safe and organized work environment. By adhering to best practices in material selection, installation techniques, and ongoing maintenance, facilities can ensure that their markings remain effective in enhancing safety and efficiency for years to come. A well-maintained marking system not only safeguards personnel but also contributes to the overall success of the facility.

Similar Questions

- What are the Benefits and Best Practices of using Color-Coding for labels and signs in Facility Marking?

- What is Facility Marking?

- How does proper Facility Marking help create a more Safe and Visual Workplace?

- What are the Best Facility Marking Techniques?

- How does Facility Marking Improve Safety Awareness and Navigation?

- What are the Benefits of Floor Marking Tape for Safety and Productivity?

- How can I prevent Warehouse Accidents with Facility Marking?