Whether working in a warehouse, factory, or industrial facility that requires printing bar codes or other media, experiencing the pain of printing these with a laser printer is excruciating. It's a hassle, produces vast amounts of waste, and can be time-consuming. It might be time to consider making the switch to a thermal printer. Thermal printing is a great alternative that allows for less waste, ease of use, and faster printing. When work environments are labeled effectively, workers are safer and more efficient, and with that being said, it's important to have to right tool for the job.

Technological advances and the speed and quality of thermal printing has made this method increasingly popular in commercial enterprises of all varieties. Movies tickets? Printed with a thermal printer. Received a receipt from an order at Chipotle? Made a label for some honey-roasted cashews from the bulk bins at the grocery store? Taken a number at the DMV? Purchased a lottery ticket? Chances are a thermal printer was used for all of these examples.

In deciding whether or not thermal printing is best for any company, it's important to examine the options available, and what this method of printing can do to improve business processes. The Lean method of Kaizen dictates that companies should always strive for continuous improvement, and integrating thermal printers into a facility is a step in the right direction.

How does a thermal printer work?

To put it simply, thermal printing uses heat to copy an image onto a chosen material. Inkjet printing uses ink to copy an image onto chosen material. In the early days of this printing technology, direct thermal printers resembled branding irons, whereas inkjet printers resembled tattoo guns. For specific detail and complicated coloring, inkjet was the clear and superior option.

Nowadays, advances have given thermal transfer printers the best of both worlds: the high-quality images of inkjet and the speed and convenience of direct thermal printers. Inkjet printing still delivers the highest quality image if paper is the medium, but for other media, thermal transfer printing is the best way to go.

What is a thermal transfer printer?

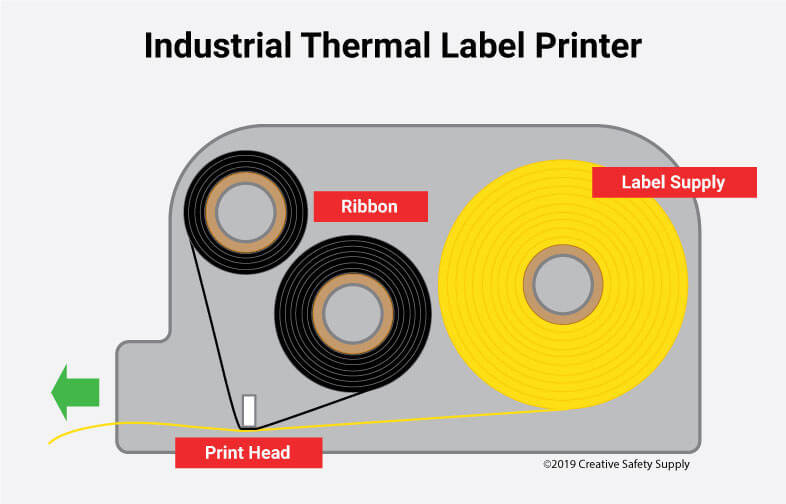

Thermal transfer printing occurs by a process that uses heat in order to produce an imagine on paper, a label, or some other such material. The image is created by melting a coating so that it stays glued to the intended material. This technique provides high-quality image printing that can't compare to other on-demand printing options.

Thermal transfer printing uses a ribbon to produce images onto desired materials. This method is ideal for environments that require printing a variety of things, since thermal printing can print effectively on a larger array of media than direct thermal models, including paper, polyester, and polypropylene materials. Thermal transfer printers are able to print pipe marking labels, wall signs, tickets, tags—just about anything. However, when changing from one material to another, the targeted material and ribbon must be compatible. This will ensure perfect performance.

The accurate media-ribbon combination can enable users to create high-quality labels that withstand environmental extremes, sun damage, chemical and water exposure, etc.

Typical uses for thermal printers utilizing thermal transfer method include:

- Pipe marking

- Inventory identification

- Instrument identification

- Instructive labels

- OSHA-compliant notifications

- Safety warnings

- Certification labels

Direct Thermal Printer Solutions

Direct thermal printers use chemically treated, heat-sensitive media that darkens when applied to a thermal printhead. Unlike Thermal transfer printers, this kind of industrial printer has no ribbon, ink, or toner. Because these don't require many components, direct thermal printers make for easy usage. Because there are less parts, they're more durable and tougher than inkjet printers. Most mobile printers—the kind that can be seen in a warehouse, for example—utilize direct thermal technology.

The downside to this method is that direct thermal images that are overexposed to heat, light, or other harsh environments will darken, consequently rendering them unreadable. Direct thermal printing isn't intended to last a lifetime, and the readability of direct thermal printing varies on usage conditions.

Best uses for direct thermal printing are for simple images, such as:

- Shipping labels

- Receipts

- Ticket printing

- Various barcode applications

Determining the Right Thermal Printer for your business

Now that the different types of printers have been defined, it's time to decide which type of printer will be best for the facility's needs.

Direct thermal printers have limited printing capacities, but most thermal transfer printers have the capability of printing either thermal transfer or direct thermal. This versatility is very valuable if a business needs to do both methods of printing. However, if they only need direct thermal capabilities, these thermal printers are generally less expensive. If the business requires any kind of labeling—from pipe marking to OSHA compliance—then a thermal transfer printer will be the smart choice.

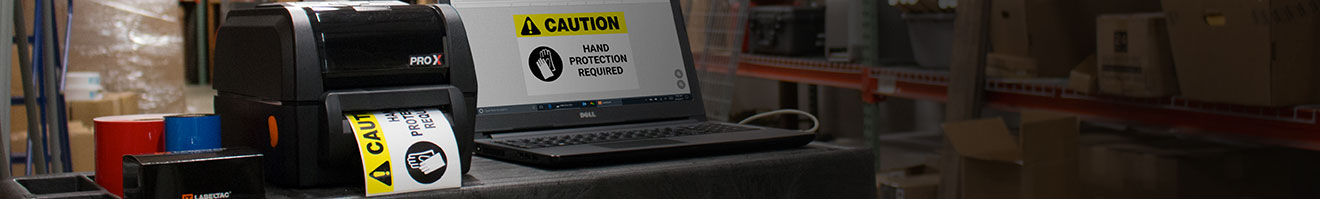

For those looking for thermal transfer printers that are easy to use, fast, and have industrial-strength toughness, LabelTac® Printers are the best option. This line of printers was designed to serve the needs of industrial facilities. These printers come with LabelSuite™ software, which makes it easy to design labels to fit any company's needs, and to include OSHA-compliant headings and signal words.

Similar Articles