Resources

Organized Workplace Articles

Lean in Different Industries

The Lean methodology originated in the manufacturing sector, buit its core principles of continuous improvement, process optimization, and employee empowerment can be effectively applied across a wide range of industries. …

Understanding The 5S Methodology Implementation

This guide highlights important strategies to implement the 5S of lean. Discover the benefits, and utilize the tools to streamline the manufacturing processes. …

Choosing to Implement a Periodic Inventory System

Read up on periodic inventory systems to make an educated decision on whether this inventory valuation system is right for your company. …

Staying Lean During a Pandemic

It’s important to stay focused on efficiency as the COVID-19 pandemic continues. Here are several Lean manufacturing techniques that can help your business continually improve, even during times of crisis. …

Cleaning the Workplace During COVID-19

Using the 5S method to clean and organize your facility is more important than ever as the coronavirus pandemic continues to impact workplace safety. …

5S Lean Training

If you’re new to the concept of 5S, you’ve probably feel confused. This article aims at providing clarity and setting you on the path toward understanding 5S and Lean. …

Tool Storage Ideas

Lean manufacturing emphasizes organization, but it can be difficult figuring out just how to get started. This article lays out some common and effective ways of getting organized quickly. …

ANSI TIA 606-B Cable Labeling Standards

ANSI TIA 606-B Cable Labeling Standards are a unified labeling method for the wires used in computer systems. These standards help businesses record data and keep their IT environments organized. Get to know these standards; they’ll help your business run more efficiently. …

Lean Healthcare (Principles for Improvement)

Implementing lean healthcare in the medical field will lead to improvement in overall performance and patient satisfaction. …

Floor Marking For 5S

Inexpensive yet endlessly practical floor markings can drastically simplify your 5S efforts, while saving you time and money. Learn more in our latest article. …

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace. …

Warehouse Management

Proper warehouse management can dramatically improve both efficiency and safety. This article covers everything you need to know. …

5 Lean Principles for Process Improvement

Learning the basics about the lean process is essential when implementing continuous improvement changes. We have broken down the lean process so its easy to understand. …

Introduction to Process Mapping

Process Mapping is used in many types of businesses to help companies streamline their production, increase profitability, reduce waste, and much more. …

Continuous Improvement (A Kaizen Model)

Facilities that focus on continuous improvement become more competitive over time and can maintain their advantages in their industry, but only if the improvement efforts are done correctly. …

How to Implement 5S in an Organization

It takes significant effort to implement a proper 5S program, but following the right steps will drive success and help the process go smoothly. …

5 Lean Manufacturing Tools that Work

These five lean manufacturing tools are essential for making your lean journey a success. …

Lean Supplies

Learn what supplies and tools you can use to make Lean manufacturing efforts successful. …

OSHA Floor Marking

Find out what OSHA has to say about marking your facility's floors. …

Cable Management

Properly marking wires can improve organization, facilitate faster maintenance, increase safety, and more. …

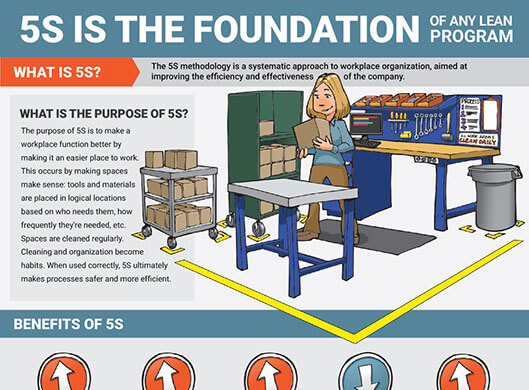

The 5S System [Lean Manufacturing Methodology]

One of the most comprehensive pages you will find on 5S. …

Tool Box Organizers – 19 Tips & Hacks for Your Tool Box

Use these tool foam organizer tips and hacks get your workspace in order and simplify your life. …

Organized Workplace Questions and Answers

What are some Strategies that can Create an Organized Workplace?

As well as helping to create a more efficient workflow and improve processes, an organized workplace has also proven beneficial to employee satisfaction, reducing their stress and assisting them in their duties. In this article, we discuss a range of strategies which can be implemented into the workplace to improve organization. Optimize workspaces The way a workspace… …

Who is responsible for organizing the workplace?

Organizing the workplace is a team effort that involves everyone in the company. From the top down, each person has a role to play in ensuring that the workplace is organized and efficient. Here are some of the people who are typically most involved in organizing the workplace: Management: Management is responsible for setting the overall… …

What are the Tools for Keeping an Organized Workplace?

An organized workplace is essential for productivity, efficiency, and safety. A cluttered or disorganized work environment can lead to lost time, increased stress, and even accidents. To keep your workplace organized, there are several tools that you can use: Labeling: Labeling helps to ensure that everyone knows where to find items and how to put them… …

What are Different Areas in the Workplace to Organize?

In a manufacturing environment, many different areas need to be organized to ensure efficiency, safety, and productivity. Here are some of the key areas in the workplace that should be organized: Workstations: Workstations should be organized so that tools and materials are easily accessible and there is enough space for workers to move freely. This can… …

What are Some Examples of Organizational Skills?

Organizational skills are the abilities that help you to manage your time, resources, and tasks effectively. They are important for success in both personal and professional settings and can help you to be more productive, efficient, and effective. Here are some examples of organizational skills: Time management: Time management skills involve the ability to plan and… …

How Can Warehouse Shelving be Organized?

Warehouse shelving is an essential part of any storage facility. It provides a place to store and organize products and materials, making them easily accessible when needed. However, if the shelving is not organized properly, it can lead to inefficiencies, lost time, and even accidents. Here are some tips on how to organize warehouse shelving: … …

What are the Best Storage Ideas for the Office?

Effective storage is essential in any workplace to keep the area organized, efficient, and safe. Here are a few storage ideas to consider: Use labeled bins or containers Clearly labeled bins or containers can help employees quickly locate and access the items they need. This can be particularly useful for small parts or tools that are frequently used. Use… …

What are the Benefits of Keeping an Organized Workplace?

There are numerous benefits to keeping an organized workplace. Understanding why it is so important to keep your facility organized will help ensure that you can get support from everyone involved. A few key benefits include: Increased productivity: An organized work environment allows employees to easily find and access necessary materials and tools, reducing the time… …

How Does 5S Organize the Workplace?

5S is a workplace organization methodology that originated in Japan and has been adopted by companies around the world. It is a set of five principles that focus on creating a clean, organized, and efficient work environment. These principles are: Sort: This involves going through all items in the workspace and removing any that are unnecessary… …

What Does it Mean to be Organized in the Workplace?

Being organized in the workplace is a crucial skill that can greatly improve productivity and efficiency. It involves creating systems and structures to manage tasks, projects, and documents in a logical and orderly manner. There are several key components to being organized at work. First and foremost, it involves having a clear plan and set of… …

What are the Different ways to Organize Storage in a Manufacturing Facility?

Running a manufacturing facility involves making sure that many different areas are running smoothly. One thing that is often overlooked is making sure that the storage in the facility is kept properly organized. Most companies need to store things like parts for assembly, items for the maintenance of machinery, completed products, and much more. There are… …

What are the Tools of Keeping an Organized Workplace?

Keeping a facility organized is not something that generally just happens on its own. The team must decide what things go in what places, who is responsible for what actions, and much more. When coming up with a strategy for organizing the workplace, it is important to consider what tools may be needed. There are… …

Who is Involved with Organizing the Workplace?

Keeping the workplace organized is going to benefit both the company and the employees in many ways. To successfully keep the workplace organized, however, it will take effort from everyone working together. This is not something that the management team can handle on their own since they must rely on the employees to do their… …

![The 5S System [Lean Manufacturing Methodology]](https://www.creativesafetysupply.com/template/images/custom/resources-page/Articles-5S.jpg)