Resources

Equipment Labeling Articles

A Brief Overview of Key Agricultural Labeling Requirements

Whether you operate a commercial farm or you are an employee at a small agricultural facility, it is important that you know all the rules and regulations that you need to follow, including proper labeling. …

NFPA 855: The Installation of Stationary Energy Storage Systems

NFPA 855 is an essential standard to follow to maintain worker safety while around stationary energy storage systems. …

Keeping Operators Safe with Machine Guarding

Machine guards are essential for facilities where employees work in close proximity to hazardous moving parts. Properly safeguarding machines prevents severe injury and death. …

MIL-STD-129: Military Marking for Shipment and Storage

MIL-STD-129 is the U.S. Department of Defense’s labeling standard for the shipment and storage of military equipment. Contractors must use military shipping labels and adhere to other DOD requirements. …

Military Equipment [Condition Tags & Labeling]

Military equipment includes weapons, aircraft, vehicles, and personal gear that was intended for use by the Armed Forces. A wide variety of materials falls under this classification, and proper labeling of their condition is essential. …

NFPA 70E [Workplace Electrical Safety]

NFPA 70E was created to help prevent injuries to workers in energized environments. If you’re working with live energy, you need to know this safety standard to stay OSHA compliant. …

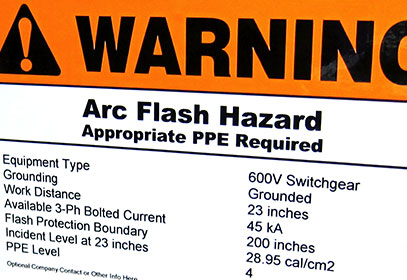

Arc Flash Labeling (Updated)

Arc Flashes are one of the most dangerous accidents that can happen in a facility. Learn how to keep your facility safe and incident-free through proper labeling. …

Solar System Labeling

In 2017, The National Electrical Code (NEC) made some significant changes to solar system labeling standards. Getting familiar with these updates will help your facility stay safe and efficient. …

Metal-Detectable Labels for FDA Food Labeling Compliance

Accidental contamination is a major worry in the food industry, and while it’s impossible to completely rule out all contamination, metal detectable labels help eliminate a significant danger. …

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace. …

Continuous Improvement (A Kaizen Model)

Facilities that focus on continuous improvement become more competitive over time and can maintain their advantages in their industry, but only if the improvement efforts are done correctly. …

5 Lean Manufacturing Tools that Work

These five lean manufacturing tools are essential for making your lean journey a success. …

Labeling Electrical Conduits

Learn how to label electrical conduits so employees can quickly identify them. …

Arc Flash and Electrical Safety

Learn how arc flash works and how it relates to your larger electrical safety program. …

Lean Supplies

Learn what supplies and tools you can use to make Lean manufacturing efforts successful. …

10 Essential Steps for Electrical Safety

Follow these 10 steps to protect people and property from electrical hazards. …

Arc Flash Software helps improve Arc Flash Safety

A review of common software programs that will help you reduce arc flash hazards. …

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it. …

Equipment Labeling Questions and Answers

Who is Responsible for Labeling Equipment?

If you are planning out a labeling strategy for your facility, you will undoubtedly have a lot of things on your mind. Thinking about where to place the labels, what type of label printer to use, what regulations you need to follow, and much more can become overwhelming. It is important, however, to make sure… …

What Equipment Needs Arc Flash Labels?

When putting labels on an electrical system, it is important to make sure that you are using the right labels in the right places. You do not want to be placing labels where they do not belong or the people working on those systems will just ignore them. This can make it more dangerous to… …

Who is Responsible for Labeling Electrical Equipment?

Electrical systems need to be properly labeled to ensure they are maintained correctly and to help ensure the safety of anyone who is working on them. It can be confusing, however, to know who is responsible for placing the labels on the system, and who will be making sure that they are kept up to… …

How Can Asset Tagging be Used for Equipment?

Keeping track of the assets owned or leased by your facility is extremely important. One of the best ways that you can do this is by using an asset tracking system. For many organizations, this means putting a label on every piece of equipment that has an asset number. The asset number will then be… …

What Type of Labeling Equipment Should I use for My Labels?

Labels are an important tool for conveying information in the workplace. They are commonly used on electrical equipment, pipes, machinery, and other areas to quickly share information about safety hazards or methods of working on a specific area of a facility. In order to properly label your equipment, you need to have the right tools… …

![Military Equipment [Condition Tags & Labeling]](https://www.creativesafetysupply.com/content/images/articles/military-equipment-th.jpg)

![NFPA 70E [Workplace Electrical Safety]](https://www.creativesafetysupply.com/content/images/articles/nfpa-70e-th.jpg)

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)