Resources

GHS Articles

Safety Data Sheets (SDS)

Safety Data Sheets contain crucial information about the classifications and associated hazards of a chemical. They follow a standardized 16-section format and are required for any facility that handles, stores, or transports chemicals. …

What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

Hazcom is designed to help employees to quickly identify hazardous chemicals. Learn more beneficial information about Hazcom. …

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

Hazard Pictograms (GHS Symbols)

More than crude drawings, these nine illustrations protect millions of people throughout a variety of industries each and every day. …

GHS Label Information

A closer look at OSHA’s Hazard Communication Standard—1900.1200—and how it applies to your facility. …

The Definitive Guide to Globally Harmonized System (GHS) Labeling

Implementing GHS has been an evolving process for many companies. Here's what you need to know. …

Material Safety Data Sheets [How-To Guide for Upgrading to SDS]

Learn the difference between the old material safety data sheets and the new GHS/HazCom safety data sheets. …

GHS Label Creation

Find out how to make Globally Harmonized System (GHS) labels in 3 steps. …

GHS Questions and Answers

What are some examples of GHS for Employee Training

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) ensures that the use of chemicals is regulated in the workplace. By providing guidance on the safe handling, storage, and use of potentially dangerous materials, employee safety is improved. In order to carry out effective employee training on GHS, we discuss key topics to… …

What is the Scope of GHS?

If you need to follow the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) then you need to know the full scope of what that covers. Most companies that use any type of hazardous chemical in the United States will need to comply with the GHS because it has been largely adopted by… …

What are Some Key Terms Used in GHS?

The Globally Harmonized System of Classification and Labeling of Chemicals, or GHS, is a system that is used to ensure companies throughout the United States are labeling their chemicals the same way. Many of the GHS standards are mandated by OSHA, which is one of the reasons that it is such a popular system. Many… …

What are GHS Hazard Groupings?

When learning about the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) you will notice that there are many different types of hazards associated with chemicals. To help make it easier to identify and deal with different risks, the GHS system groups similar types of hazards together so they can be dealt with… …

What are the Different Health Hazard Classes?

When dealing with workplace safety, there are a variety of different risks that need to be evaluated. One of the most significant is going to be the different health hazards that can exist within a workplace. Within the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) multiple different health hazard classes need to… …

What are the Different Environmental Hazard Classes?

When learning about the different types of hazards in the workplace, one common category is environmental hazards. This is a common phrase used in many different areas of workplace safety, including the Globally Harmonized System of Classification and Labeling of Chemicals, or GHS. Learning about the different categories of environmental hazards will help to ensure… …

Do All Hazard Classes and Categories Require a Pictogram?

One of the most important things to be aware of when it comes to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is the use of pictograms. Pictograms are simple images that can make it immediately clear what type of hazard a chemical can cause. There are quite a few different pictograms… …

What are the two major elements in the Globally Harmonized System?

Given the full title of GHS, the Globally Harmonized System (GHS) of Classification and Labeling of Chemicals, the two key components of GHS are Classification and Labeling. Almost twenty years ago, the United Nations officially adopted this universally accepted system to avoid confusion around hazard communication. A Harmonized System of Classification OSHA aligned their Hazard Communication Standard… …

How are toxic materials classified under GHS?

The OSHA-adopted Globally Harmonized System provides the framework for classification with defined classes and categories for hazardous chemicals. GHS classifies chemicals into three hazard classes: health hazards, physical hazards, and environmental hazards. Toxic materials are classified as a health hazard, further described in the following 10 health hazard categories: Acute toxicity Skin corrosion Skin irritation … …

Is the CAS number the same as the MSDS number?

There isn’t one, but two distinct numbers on a Safety Data Sheet for hazardous chemical identification. Those are the CAS registration number and the SDS ID number (formerly known as the MSDS number). These numbers are not interchangeable! Sometimes these can be mistaken for each other, but in fact they serve very different purposes and… …

What is GHS labeling?

GHS stands for Globally Harmonized System (of Classification and Labeling of Chemicals). It is a set of standards that was developed and is managed by the United Nations. It was designed originally to replace the different standards that were used in countries around the world. With the ever increasing amount of global business, this is… …

What is GHS?

GHS stands for Globally Harmonized System, which is actually a shortened version of the Globally Harmonized System of Classification and Labeling of Chemicals. This is a set of standards for classifying and labeling potentially hazardous chemicals to help bring people from around the world together for the safety of everyone. As of the last release… …

What does SDS stand for?

SDS stands for Safety Data Sheet. A safety data sheet is a document that contains detailed information about the safety and health impacting aspects of various substances and products. They are sometimes also called material safety data sheets (MSDS) or product safety data sheets (PSDS). Companies that produce, ship, use, or otherwise interact with potentially… …

Why is GHS necessary and important?

The Globally Harmonized System was developed decades ago in order to help create a standard for the labeling and classification of chemicals that could be used by companies around the world. Prior to this standard, companies shipping or receiving chemicals would have to relabel and classify them to comply with local ways of doing things.… …

Who developed GHS and who regulates it?

The Globally Harmonized System of Classification and Labeling of Chemicals (GHS) was first developed back in 1992. This was at the Rio Conference on Environmental and Development by the United Nations (more commonly called Earth Summit 1992). At this event, the International Labor Organization and the Organization for Economic Co-operation and Development, along with several… …

When is GHS required?

On March 26th, 2012 the Occupational Safety and Health Administration (OSHA) officially adopted the Globally Harmonized System. This was done in a revision to their existing Hazard Communication Standard, which had been in place for some time. By updating their system to match GHS, OSHA helped to ensure that chemicals are more universally labeled and… …

What is GHS training?

Whether your company has been using the GHS standards for years, or you are just starting to implement it in your facility, proper training is critical. If your employees, contractors, and other key people aren’t properly trained in GHS, it will dramatically reduce its effectiveness, which can cause a lot of safety problems. All good… …

Does OSHA follow GHS?

Originally, the Globally Harmonized System, or GHS, was not a part of OSHA at all. In fact, OSHA had its own set of standards governing how to label hazardous chemicals to improve safety. As of 2012, however, OSHA aligned their HazCom standards with the globally popular GHS system. This has gone a long way in… …

What is GHS compliance?

The Globally Harmonized System of Classification and Labelling of Chemicals, or GHS, is a popular set of standards that is used to classify chemicals and their associated hazards. It is used by companies around the world, and even mandated by many regulatory agencies like OSHA. Remaining in compliance with the standards put forth by GHS… …

How do I read and understand a GHS Safety Data Sheet (SDS)?

When working with chemicals or other hazardous substances it is important to understand the dangers so that proper precautions can be taken. For facilities following the Globally Harmonized System (GHS), this starts with the GHS label. The label will include a variety of different types of information to help identify the chemical, present the various… …

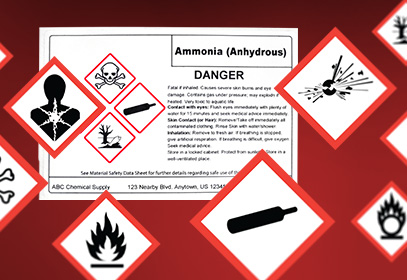

How do I read GHS labels?

When looking at GHS labels most people will immediately recognize the various pictograms that are surrounded by the red diamond. This is the most important part of the GHS label because it allows everyone to quickly understand the type of danger that is present when working with the chemical that has been labeled. In many… …

How can I properly create GHS labels?

If you use GHS in your facility it is critical that you know how to create the labels that you need to remain in compliance. This is even more important if you operate in the United States or another country where GHS standards are mandatory. Creating or attaining GHS labels is quite easy and can… …

How can I make my own GHS labels?

Any facility that uses GHS will need to have easy access to labels that depict the GHS pictograms. These labels will be used on all containers used to store hazardous chemicals, any shipping boxes or trucks, and other areas where these chemicals are used. Fortunately, it is a simple process to create your own GHS… …

How is GHS implemented?

Industries around the world use a wide-range of different chemicals to create products and accomplish other tasks. Many of these chemicals have properties that can make them very dangerous if not stored, shipped, and used properly. Given the fact that companies from around the world often work together to use, store, and ship these chemicals,… …

How many hazard groups are there in GHS?

The GHS system is used to identify specific hazards associated with various chemicals that are used in different industries. The hazards are identified using nine different pictograms, each of which are associated with a different type of risk. A chemical will be labeled with one or more of these pictograms to make it easy for… …

Can GHS pictograms be black and white?

The GHS system uses a series of nine pictograms that represent different types of hazards that are present when using different types of chemicals. When buying, selling, storing, shipping, or using any type of hazardous chemical it is important to label the containers or other items with the proper pictograms. The pictograms are printed in… …

What are GHS codes?

When most people think of the GHS system, they think of the various pictograms representing different hazards. While that is certainly the most well-known aspect of GHS, it is really just the beginning. GHS also includes standards and information about hazard statements, signal words, and more. One very important part of the GHS system are… …

What are GHS physical hazards?

In the GHS system it is important to be aware of all the different hazards that exist in a given chemical or solution. One of the most common hazards is the physical hazard, which is used for chemicals and mixtures where there are dangers that can cause physical damage. This would include explosions, fires, and… …

When are GHS Safety Data Sheets (SDS) Required?

In the GHS system most of the focus is put on creating simple labels that include easy to understand pictograms so that people know what hazards are present at just a glance. This is important so that people from around the world will recognize the hazards and be able to respond quickly. While this is… …

What are GHS signal words?

The GHS standard primarily uses pictograms to convey information about hazards related to chemicals. It is used around the world, which is why the pictograms are much more important than words or other methods of communication. That being said, GHS does have two signal words that can be used to help provide emphasis and inform… …

What is the GHS format?

The Globally Harmonized System (GHS) of Classification and Labeling of Chemicals is a globally recognized standard for identifying various hazardous chemicals. It is used whenever storing, transporting, or acquiring any type of chemical that presents a danger to employees, a facility, the environment, or other areas. In addition, any container or machine using these chemicals… …

Are GHS pictograms and hazard labels the same?

The GHS, or Globally Harmonized System, uses a set of nine different pictograms to represent different hazards related to chemicals. This system is used around the world to help communicate the dangers so that employees and others in the area can respond to them properly. Most people have even seen the GHS pictograms on the… …

Are GHS labels required?

GHS labels are used in countries around the world to help identify specific hazards related to industrial chemicals. The standards require simple pictograms to be used so that anyone who sees them (and is familiar with the GHS standards) will know what the danger is. Since there are no written or spoken words used on… …

How many GHS pictograms are there?

The Global Harmonized System of Classification and Labeling of Chemicals (GHS) uses simple pictograms to identify the various hazards that can be present with chemicals. Since this system is used around the world, it was important to use the images rather than words, which would cause difficulty due to language barriers. All the pictograms are… …

What does GHS stand for?

In manufacturing and other industries, the acronym GHS stands for Globally Harmonized System. It is also often called the Globally Harmonized System of Classification and Labeling of Chemicals because it is a set of standards used when labeling systems. This system was developed by people and companies from many different nations and authorities in order… …

![Material Safety Data Sheets [How-To Guide for Upgrading to SDS]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-msds-sds.jpg)