Why is Color-coding Important?

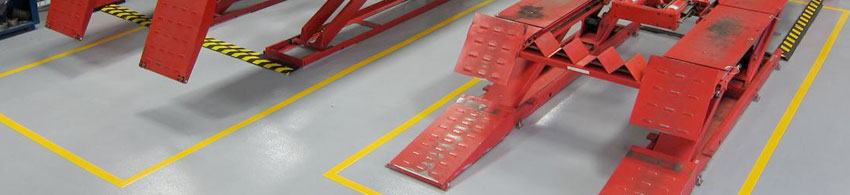

Color-coding is a simple but effective way to enhance communication, organization, and safety in any workplace. Color-coding is the use of different colors to convey specific meanings or associations, such as hazards, functions, locations, or instructions. Color-coding can be applied to various types of visual cues, such as labels, signs, floor markings, pipe markers, safety tags, and more.

In this article, we will focus on how to use color-coding for labels and signs in facility marking. Facility marking is the process of applying markings to various surfaces and objects in the workplace to provide important information. Facility marking can help identify hazards, designate work zones, indicate traffic flow, provide directions, and more. By using color-coding for labels and signs in facility marking, you can improve both safety and productivity in your workplace. Color-coding can help you:

Emphasize important information

Using colors that contrast with the background or stand out from the surroundings can help draw attention to critical information or warnings. For example, you can use red labels or signs to mark fire protection equipment or emergency exits; yellow labels or signs to mark caution areas or obstacles; or orange labels or signs to mark energized or moving parts.

Keep your facility organized by showing associations

Using colors that match or correlate with the function or purpose of each area or object can help create a sense of order and consistency in your workplace. For example, you can use green labels or signs to mark finished goods or quality control areas; blue labels or signs to mark raw materials or inventory areas; or purple labels or signs to mark waste or scrap areas.

Provide critical information at the point of need

Using colors that indicate the action or location can help guide your workers and visitors to navigate your workplace and perform their tasks efficiently. For example, you can use arrow-shaped labels or signs to mark the direction of traffic or movement; number-shaped labels or signs to mark the sequence of steps or processes; or word-shaped labels or signs to mark the name of a zone or a machine.

Enhance communication and visual management

Using colors that display relevant information or data can help communicate with your workers and visitors effectively and monitor your performance and progress. For example, you can use label-shaped labels or signs to mark the identification or specification of a product or a tool; sign-shaped labels or signs to mark the status or condition of a machine or a process; or chart-shaped labels or signs to mark the goals or metrics of a project or a team.

To achieve these benefits, you need to follow some best practices when using color-coding for labels and signs in facility marking. Here is a small list of actions you could take in order to increase safety and ensure facility efficiency:

Conduct a facility assessment

Before you start applying any labels or signs, you need to assess your current facility and identify the areas that need improvement. You can use tools such as 5S, Gemba walks, or Kaizen events to evaluate your workplace and find out what information is missing, unclear, or outdated. You should also involve your workers in the assessment process and get their feedback and suggestions.

Choose the right label and sign products

There are many types of label and sign products available in the market, such as vinyl labels, magnetic signs, reflective labels, custom labels, etc. You need to choose the products that suit your needs and preferences. Some factors to consider are durability, visibility, ease of installation and removal, cost-effectiveness, and compliance with standards and regulations.

Follow a color-coding system

One of the best ways to make your labels and signs more visual and effective is to use a consistent color-coding system throughout your workplace. Color-coding can help create contrast, highlight important information, and reduce confusion. You can use colors to indicate different types of hazards, work zones, equipment status, inventory levels, etc. You can follow the standard color codes recommended by OSHA or ANSI, or create your own custom color scheme based on your specific needs.

Use clear and concise messages

Another important aspect of labels and signs is the content of the messages that you display on them. You need to make sure that your messages are clear, concise, accurate, and relevant. You should avoid using jargon, abbreviations, or acronyms that might confuse your workers or visitors. You should also use simple and easy-to-understand symbols or pictograms whenever possible to supplement or replace text.

Review and update your labels and signs regularly

Labels and signs are not a one-time project; they are an ongoing process that requires regular review and update. You need to monitor the condition and effectiveness of your labels and signs and replace or repair them as needed. You also need to keep up with any changes in your workplace layout, processes, equipment, or regulations that might affect your labels and signs. You should conduct periodic audits and inspections to ensure that your labels and signs are always up-to-date and compliant.

By following these best practices, you can use color-coding for labels and signs in facility marking to improve safety and productivity in your workplace. Color-coding can help you create a visual workplace that enhances communication, organization, and efficiency in your organization.

Similar Questions

- What are the Benefits of Floor Marking Tape for Safety and Productivity?

- How does proper Facility Marking help create a more Safe and Visual Workplace?

- What are the Best Facility Marking Techniques?

- What is Facility Marking?

- What are the Best Practices for Installing and Maintaining Facility Marking Products?

- How can I prevent Warehouse Accidents with Facility Marking?

- How does Facility Marking Improve Safety Awareness and Navigation?