Resources

6S Articles

Lean Safety | Understanding the Lean 6S Methodology

Implementing lean safety can result in safer and more efficient working conditions that minimize errors and require fewer corrective measures. …

6S: Safety

Safety is the additional sixth step to the traditional 5S method. A company that implements 6S focuses on improving organization and efficiency, with an emphasis on safety throughout each step. …

Lean Supplies

Learn what supplies and tools you can use to make Lean manufacturing efforts successful. …

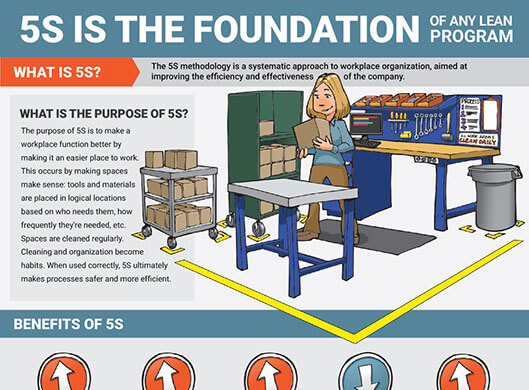

The 5S System [Lean Manufacturing Methodology]

One of the most comprehensive pages you will find on 5S. …

6S Questions and Answers

How Can Technology Improve the Effectiveness of 6S in Modern Workplaces?

In the rapidly evolving landscape of modern workplaces, technology plays a pivotal role in driving efficiency and innovation. When integrated with established methodologies like 6S, it can lead to a transformative impact on organizational operations. In this article, we'll explore how technology enhances the effectiveness of 6S, paving the way for more streamlined, connected, and… …

How does Employee Engagement Affect 6S Implementation?

The success of any workplace improvement initiative hinges on the active involvement and commitment of employees. 6S methodology, known for its structured approach to workplace organization and process improvement, is no exception. In this article, we'll explore the critical link between employee engagement and the effective implementation of 6S, shedding light on how a motivated… …

Is 6S Suitable for Non-Manufacturing Environments?

While 6S methodology has found significant success in manufacturing settings, its applicability in non-manufacturing environments is a topic of interest. The principles of 6S, with an added emphasis on safety, can bring transformative benefits to a wide range of workplaces beyond the factory floor. In this article, we'll explore the adaptability of 6S in non-manufacturing… …

How Can 6S Improve Workplace Safety and Reduce Incidents?

In the dynamic landscape of modern workplaces, safety is a paramount concern. Businesses are constantly seeking methodologies that not only enhance efficiency but also prioritize the well-being of their employees. 6S methodology, an advanced extension of the 5S system, emerges as a powerful tool in achieving both objectives. In this article, we'll explore how the… …

What Are the Key Steps in Implementing 6S for Lean Manufacturing?

In the pursuit of lean and efficient manufacturing processes, the implementation of methodologies like 6S can make a significant difference. 6S, an extension of the well-known 5S system, brings an added emphasis on safety, further enhancing workplace optimization. In this article, we'll dive into the key steps involved in implementing 6S for lean manufacturing, providing… …

What is 6S Methodology and How Can It Revolutionize Workplace Efficiency?

In the pursuit of operational excellence, businesses are constantly seeking methodologies that can streamline processes and enhance productivity. One such powerful framework is 6S methodology, an advanced extension of the renowned 5S system. In this article, we'll delve into the fundamentals of 6S, how it differs from its predecessor, and how it has the potential… …

Why Should You Implement 6S in Your Workplace?

In today's fast-paced and competitive business environment, efficiency and organization are paramount. This is where 6S methodology steps in as a powerful tool for optimizing workspaces and processes. In this article, we'll delve into what 6S is, how it functions, and provide real-world examples of its impact, ultimately showcasing why it's a vital framework for… …

What are some examples of the Differences between 5S and 6S?

While 5S and 6S both have a goal of optimizing the workplace, they each have differences in approach and application. Below you can find an explanation of 5S and 6S with a real-life example of when each would be used in a workplace scenario, helping to bring the uses of the methodologies to life. The… …

Can You Use a Checklist for 6S?

In the realm of workplace optimization and safety, the 6S methodology stands as a beacon of efficiency and excellence. But can you leverage the power of a checklist to enhance your 6S endeavors? In this comprehensive exploration, we uncover the value of using a checklist when setting up a 6S safety program, providing you with… …

How Do I Set Up a 6S Safety Program?

Embarking on the journey of implementing a 6S safety program is a pivotal step towards establishing a workplace where efficiency and employee well-being harmoniously intertwine. In this comprehensive guide, we delve into the intricacies of setting up and using 6S for safety programs, providing you with actionable steps and insights that pave the way for… …

How Do I Use 6S for Safety?

The modern workplace is a dynamic ecosystem where the pursuit of both operational excellence and employee well-being are paramount. In this landscape, the integration of 6S safety principles becomes a guiding light, illuminating the path toward creating an environment where safety and efficiency harmoniously coexist. But how does 6S safety work? In this comprehensive guide,… …

How Does 6S Safety Work?

The realm of workplace optimization and employee well-being is a tapestry woven with the threads of methodologies like 6S safety. But how exactly does 6S safety work its magic? In this comprehensive exploration, we unravel the intricate mechanisms that underpin the fusion of 6S principles and safety practices, while providing some examples. By delving into… …

What are Some Examples of 6S?

The principles of 6S stand as pillars of organizational excellence, reshaping workspaces into efficient, safe, and well-organized environments. It's one thing to know the principles and rules of 6S, but it's also important to see how they could be applied in the real world. As organizations across various industries embrace Lean methodologies, the question arises:… …

What are the Rules of 6S Safety?

In the realm of workplace organization, efficiency, and employee well-being, the rules of 6S safety emerge as guiding principles that shape organizational success. As organizations strive to create environments that prioritize safety, enhance efficiency, and foster a culture of continuous improvement, understanding and embracing the rules of 6S safety become imperative. In this comprehensive exploration,… …

What is 6S Safety?

In the dynamic landscape of industrial and organizational management, the concept of 6S safety has emerged as a powerful force for transforming workplaces into thriving hubs of efficiency, organization, and employee well-being. As organizations strive to optimize their processes, the question arises: What is 6S safety, and how does it contribute to the overall success… …

What is the Definition of 6S?

In the realm of Lean Manufacturing, the concept of 6S stands as a beacon of organizational efficiency, process optimization, and workplace excellence. However, what precisely does 6S entail, and when should you attempt to implement it in your organization? In this comprehensive exploration, we peel back the layers of this methodology, uncovering its fundamental definition… …

When is the Best Time to Set Up a 6S Safety Program?

When an organization embarks on the journey of Lean Manufacturing, the significance of workplace safety becomes intertwined with the pursuit of efficiency and excellence. A few common question that arises are these: What is 6S? What does it have to do with safety? When should a 6S safety program be established? Who is responsible for… …

Who's Responsible for 6S?

In the world of Lean Manufacturing, the concept of 6S plays a pivotal role in optimizing workplace efficiency and creating an environment of continuous improvement. The question often arises: Who's responsible for implementing and maintaining the 6S methodology? In this article, we delve into the distribution of responsibilities within an organization when it comes to… …

Why is 6S important?

6S is an important tool used in Lean Manufacturing to improve workplace efficiency. It is a systematic approach to organizing and maintaining a safe and efficient workplace environment that also improves overall quality. 6S stands for Sort, Set in Order, Shine, Standardize, Sustain, and Safety. Implementing 6S can help reduce waste, optimize resources, and create… …

Why was 6S Developed?

When asking about why 6S was developed, you must look at two distinct things. First, looking at why the precursor to 6S was developed. 5S has been around for quite a long time and was developed to help companies find different types of waste in the workplace and eliminate it. This helps the company to… …

Is 6S the Same as Six Sigma?

The concepts of 6S and Six Sigma are often used together since they are both related to improving the way that a business operates. While the names seem similar, and they are often discussed together, they are actually two separate and distinct systems that can be used by a company. Companies can implement these systems… …

What is a 6S Audit?

If you own or manage a company, you will want to do everything you can to eliminate waste and improve the efficiency of the organization. For many companies, the best way to do this is to start implementing 6S strategies. 6S is a very popular concept that takes six separate ideas, each of which start… …

What are the Tools of 6S?

6S is one of the most popular and most effective workplace improvement strategies used today. By using the six strategies listed in this methodology, you will be able to better find and eliminate waste throughout your facility. Of course, just knowing about different steps you can take to get rid of waste is not going… …

What are the Benefits of 6S in Production?

If you are looking at the 6S system for your facility, you will undoubtedly want to know about the benefits that it can provide. Implementing workplace improvement policies like 6S will take some work, so you want to ensure that the benefits will outweigh the costs when it comes to production improvements. 6S (and 5S) have… …

What are the 6S principles?

If you are looking for ways to improve the efficiency of your company, you have likely run across the concept of 6S. This is an excellent tool that is used by millions of companies around the world to try to find and eliminate waste in the workplace, which helps them to operate more efficiently. The first… …

Is 6S safer than 5S?

Many companies today are debating whether they should implement the traditional 5S tools or move to the newer 6S option. On the surface, the biggest difference is that the 6th S in 6S stands for safety. This should mean that safety gets more focus with 6S than 5S, but many people wonder whether facilities that… …

Is 6S still considered Lean?

Running a Lean manufacturing facility is a great way to make sure that your company is operating as efficiently as possible. The concept of Lean businesses focuses on finding and eliminating all different types of waste and running as efficiently as possible. There are many different strategies that can be followed to attempt to achieve this… …

How is 6S different from 5S?

If you are looking for ways to improve the efficiency of your company, you have likely heard or read about concepts like 5S and 6S. Learning about each of these options, and knowing how 5S is different from 6S, will help you to decide which of the options is going to be best for you… …

What Does 6S Stand For?

One of the most popular Lean tools used today is known as 5S, which can help to improve processes in just about every working environment. The 5 S’s in this tool stand for sort, set in order, shine, standardize, and sustain. Many people are pushing for the adoption of a 6th S, which would stand… …

![The 5S System [Lean Manufacturing Methodology]](https://www.creativesafetysupply.com/template/images/custom/resources-page/Articles-5S.jpg)