Resources

Tool Organization Articles

Implementing 5S | Tools and Training

Many businesses decide to implement a 5S program as a way to standardize procedures, increase orderliness, and improve efficiency. …

Safety Protocols for Construction Sites

To ensure the safety and functionality of construction workers, implementation of safety protocols are a requirement that should be exercised in a robust manner. …

FOD: How to Control and Prevent Foreign Object Debris

FOD is an acronym for Foreign Object Debris and the consequences caused by this debris, Foreign Object Damage. Controlling FOD is critical in both the aviation and manufacturing industries. …

Tool Storage Ideas

Lean manufacturing emphasizes organization, but it can be difficult figuring out just how to get started. This article lays out some common and effective ways of getting organized quickly. …

Perpetual Inventory System

Using a perpetual inventory system is a great way to keep track of inventory, ordering, and other related tasks in order to keep your business running efficiently. …

Lean Supplies

Learn what supplies and tools you can use to make Lean manufacturing efforts successful. …

Tool Box Organizers – 19 Tips & Hacks for Your Tool Box

Use these tool foam organizer tips and hacks get your workspace in order and simplify your life. …

Tool Organization Questions and Answers

How can tool organization optimize my workplace?

Productivity is made up of multiple factors and the organization of workplace tools is no exception. For a business to reach their full operational capability, having a strong organization system in place throughout the workplace will help to streamline processes and maintain operational efficiency. In this article, we discuss some of the key ways to… …

How can I organize drawers of tools?

When you have a large number of tools, you need to keep them somewhere that they are easy to access so that you can use them without delay. For most businesses, this means having them in drawers. These drawers can be part of a dedicated tool storage system or just normal drawers that are used… …

How are tools organized in drawers?

If your company uses a lot of tools, you need to make sure that they are kept organized in drawers when they are not in use. This will help to make it easier for people to find them when they are needed. In addition, it will help to keep them from getting damaged and can… …

How can tools be organized with sockets?

Keeping tools organized is always a challenge, but it becomes even more difficult when each tool has several pieces that are used. This is the case when working with socket wrenches and other tools that use sockets. In many situations, you will have dozens, or even hundreds, of different sizes and types of sockets that… …

How is tool foam cut?

Foam organizers are an excellent way to create a custom tool organization system in your tool box. Two sheets of closed-cell foam are cut to fit inside the drawers of a tool box, a dark layer of foam on top and a bright bottom layer on bottom. By cutting out the shape of the tools… …

How can workplaces encourage employees to clean and sanitize their tools?

Keeping the workplace sanitized and disinfected during an infectious disease outbreak, like that of Covid-19, is essential in preventing rapidly spreading disease. However, creating this type of safe workspace cannot be done if not all employees or their employers are on board with new sanitization protocols. A large number of factors are involved in encouraging employees… …

What is closed cell foam?

Closed cell foam is a material that is used in a wide range of different environments because it is strong, yet flexible. The material has millions of internal pores (cells) that are packed very tightly together, but are not connected. This is where the name ‘closed cell’ comes from. Depending on the exact type of… …

How can a tool chest be organized?

If you work with tools of almost any sort, you undoubtedly know the frustration of not being able to find the tools you need when you need them. You also know how much it costs when you lose (or have stolen) and important tool because you couldn’t properly track them. To solve these problems, it… …

How can toolboxes be organized?

There are few things more frustrating than reaching into a toolbox to find a cluttered mess and being unable to find the one tool that you need. Organizing a toolbox, however, can also be quite difficult if you don’t know what to do. Even placing everything in the right spot once will only keep it… …

What are different types of tool organization?

At Creative safety Supply we offer a variety of solutions when it comes to organizing tools in the workplace. A workplace could use one of these strategies or a combination of a few for an effective tool organization strategy. Having effective tool organization strategies in the workplace will help to reduce wastes, save time, and… …

What are the cons of using a toolbox?

Using a toolbox and tossing tools in there with no organization plan will not only waste resources, but could lead managers to reordering unnecessary replacement tools, or workers getting injured. Purchasing a toolbox is a good step in the right direction of tool organization, but it shouldn’t stop there. Many toolboxes lacking an organization strategy… …

How can the use of colors improve tool organization?

Using color is an excellent and effective tool for nearly any organizational efforts of a workplace. Both color coding and using a two-color organization system can add an extra level of organization to your strategy. Whether tools are organized with a pegboard or tool foam, the use of color can be a huge advantage. Using… …

What should my first step in tool organization be?

Taking a cue from 5S, the first step of tool reorganization should be to sort. Sorting will help to get rid of common problems almost immediately including getting rid of tools and materials impeding workflow, reduce time wasted looking for parts and tools, and eliminating safety hazards that have resulted from a cluttered workplace. Before… …

How can I use labels for tool organization?

One of the oldest and most effective organizational strategies used in any application is labeling, and labels used alongside other tool organization strategies are an easy way for workers to quickly identify proper placement of tools and materials. Bins, toolboxes, tool chests and drawers are all areas where labels can be placed. Any drawers that contain… …

Who benefits from a new tool organization strategy?

Many parties benefit from tool organization in the workplace including workers, managers, and customers. By eliminating wastes and streamlining the manufacturing, all parties involved will be benefitted in some way. Ultimately, by having an organized system for tools and materials will affect, and improve, a business’ bottom line by creating a better-looking facility and that… …

How can shadow board tape help my tool organizational efforts?

Vinyl shadow board tape is an extremely versatile tool for organizational efforts. Vinyl shadow board tape can be used on pegboards, inside drawers of a toolbox, in a cabinet, or other places you’re utilizing tool organization. Tool outline vinyl is available in ten different colors, so you can truly customize and color-code your organization. We… …

What are the benefits of using tool foam for organization?

Tool foam offers many benefits when it comes to organization including customization, durability, and protection for the tools. The foam sheets in Creative Safety Supply’s tool foam kits have been developed to last for years to come. The closed-cell foam effectively reduces liquid and gas flow from entering. This material is ideal for industries where… …

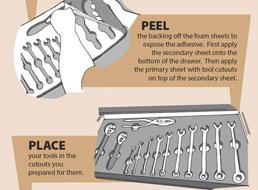

How do I organize using tool foam?

Tool foam is an easy and cost-effective option for adding an organizational strategy to an existing toolbox. Whether it’s a manufacturing factory or an auto body shop, a tool chest or a too box, customizable tool foam can greatly impact their tool organization efforts. We offer the following steps and tips when starting and implementing tool… …

How do I organize with a pegboard?

Pegboards are one of the oldest strategies used for tool organization and has been around for decades. Pegboards can often be found in a garage or workshop but are also extremely useful in a workplace. While pegboards do take up a considerable wall space, it also gives you the advantages of seeing all of your… …

How can tool organization reduce waste?

While it may seem logical to put tools in toolbox drawers and call it organized, you may be wasting more resources than you realize. Wasted resources, whether it’s time, money, or movement, are all at stake when a toolbox or workbench is cluttered and disorganized. By implementing a new tool organization strategy, a noticeable improvement… …

Is tool organization Lean?

Lean manufacturing and its related strategies are focused on streamlining processes and reducing waste with organization efforts a main component. Organizing the workplace to help the flow of processes is important and by keeping tools in a logical order, you can ensure workers will be able to locate tools quickly and keep the process moving.… …

Why is tool organization important?

Tool organization can be extremely beneficial to any kind of facility. It may seem like a hassle, but it will help workplaces run more smoothly and ultimately affect the bottom line. The following are just top five reasons to keep an organized workbench, toolbox, or workspace: Reduce wasted time: When tools are not organized, workers… …

What tools can be organized?

When you first think of tools that can be organized, you may think of hammers, wrenches, screwdrivers, etc. first. While it is important these tools are organized in a logical order, your tool organization can apply to much smaller, and much bigger tools. Whether it is a large power saw or a collection of screws… …

How is tool organization apart of 5S?

The five key components of the 5S methodology are sort, set in order, shine, standardize, and sustain. These steps can apply to nearly any area of a facility including workbenches, toolboxes, work cells, aisles, shelves, and much more. Here is how you can use 5S as a strategy to organize tools: Sort: Go through the… …

What is tool organization?

Tool organization is much more than putting tools in a toolbox and separating tools by drawers. While this may seem like the logical solution to organizing the workplace, there are a few simple strategies you can use to increase organization and reduce waste. Waste comes in many forms, and a lack of organization can lead… …