What is a Fault Tree Analysis (FTA)?

A fault tree analysis is a top-down, problem-solving methodology where the starting point of the analysis is the top-level undesired event (e.g, system failure), which is followed by systematically breaking down the reasoning behind each situation, such as its potential causes, contributing factors, and basic events (component failures).

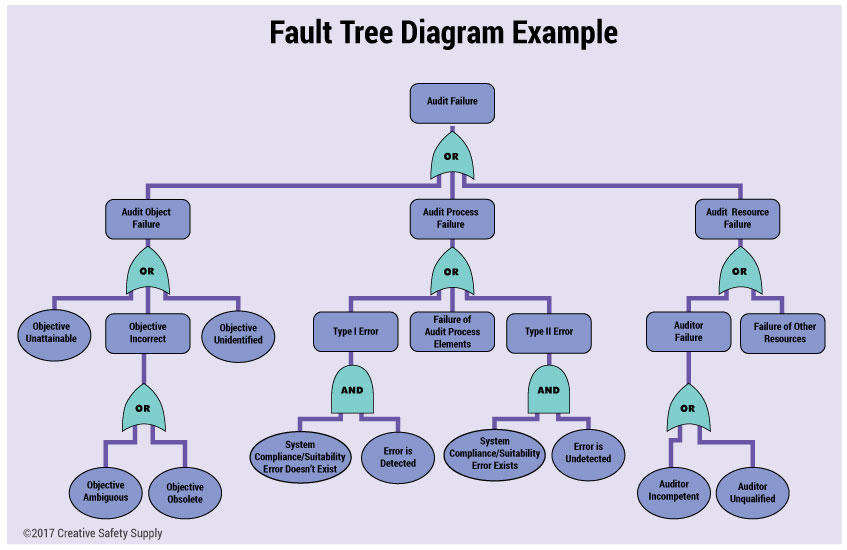

Typically known for the fault tree analysis diagram, which uses symbols and logic gates and/or to show the correlation between each event. Take a look at the fault tree diagram provided, where the first and foremost place is reserved for the worst-case scenario. In this case, it’s an audit failure followed by the reasoning that led to said undesired event.

The fault tree analysis (FTA) is a problem-solving methodology. It addresses the root cause of the problem in a template format, providing the reasoning that led to each situation. By understanding these components, the responsible personnel can avoid certain actions that led to the chain of events in the first place.

An easy and effective way to begin the analysis itself is by utilizing a template. With a template already mapped out, the important and relevant information is then plugged into the diagram. Organizing information and visually representing paths and relationships between the elements of a possible system failure can help managers identify the cause of known issues and predict potential concerns. Finding the root cause allows issues to be resolved as efficiently as possible and will help to improve the system effectively or design a new system. To learn more about Fault tree analysis (FTA), refer to our comprehensive guides on our website. With Creative Safety Supply, you can stay ahead of the game with ease.

Similar Glossary Terms

- FMEA (Failure Modes and Effects Analysis)

- Job Safety Analysis (JSA)

- DFMEA (Process Failure Modes and Effects Analysis)

- CTQ Tree

- Root Cause Analysis

- PFMEA (Process Failure Modes and Effects Analysis)

- FRACAS (Failure Reporting, Analysis and Corrective Action System)

- Safety Engineering

- JHA