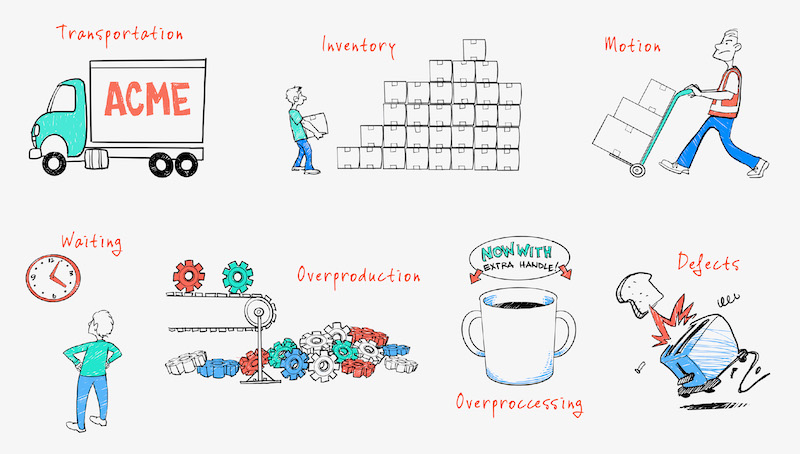

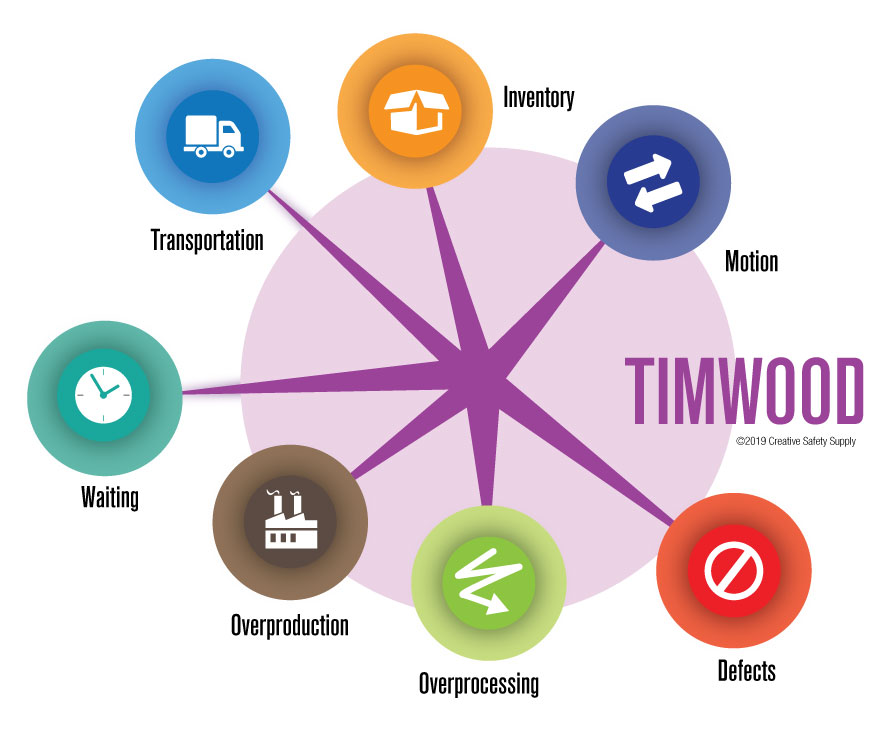

The seven wastes of manufacturing can be difficult to remember, but the acronym TIMWOOD makes it easy. Each letter in the acronym represents one of seven wastes:

Transport: Unnecessary movement of goods, equipment, and people. Results in time wasted and materials are more likely to be damaged.

Transport: Unnecessary movement of goods, equipment, and people. Results in time wasted and materials are more likely to be damaged.

Inventory waste: There are different views as to whether or not excessive inventory should be included in these wastes, as inventory (no matter how much) is considered an asset. Having too much inventory, however, can lead to longer lead times, damaged or defective products, and inefficient use of capital. Trying to maintain excessive inventory means reducing the amount of available storage space and utilizing extra resources just to manage it.

Motion waste: Unnecessary, dangerous, and complicated movements are wasteful; they can cause harm to employees, damage to equipment, or defects in the product.

Waiting and Delays: Waiting is often an easy waste to overlook. The time that is lost due to a lull in productivity is considered a waste. This usually happens when workers need to wait on material or when production is halted for unexpected equipment maintenance.

Overproduction waste: Did you know overproduction can lead to other types of waste while hiding the need for improvement? When production exceeds customer demand, facilities are left with excessive goods to store and manage.

Overproduction waste: Did you know overproduction can lead to other types of waste while hiding the need for improvement? When production exceeds customer demand, facilities are left with excessive goods to store and manage.

Over-Processing: A product or service that has more features or capabilities than required or expected by the company would be considered over-processing. It is important for businesses to understand what their customer requires from the product and eliminate any tasks or processes that are not useful or necessary to those requirements.

Defects: Many consider defects to be the worst of the seven wastes. Characterized as products that do not meet company standards, these products must either be scrapped or reworked, thus adding costs to the operation but not adding value for the customer.

Additional TIMWOOD facts:

- TIMWOOD stands for the seven wastes of Lean: transportation, inventory, motion, waiting, overproduction, overprocessing, and defects. These are the types of activities or processes that do not add value to the customer or the product. Source: https://leanscape.io/8-wastes-of-lean/

- TIMWOOD was developed by the Lean manufacturing experts at Toyota as part of the Toyota Production System (TPS), which is a set of principles and practices for improving quality, efficiency, and customer satisfaction. Source: https://theleanway.net/The-8-Wastes-of-Lean

- TIMWOOD can be applied to any organization or industry, not just manufacturing. By identifying and eliminating waste, organizations can reduce costs, increase productivity, and enhance customer loyalty. Source: https://safetyculture.com/topics/timwood/

- TIMWOOD can be used as a framework for conducting a value stream mapping (VSM), which is a tool for visualizing the flow of materials and information from the supplier to the customer. VSM can help identify the sources of waste and the opportunities for improvement. Source: https://datamyte.com/blog/guide-to-timwood-lean-framework/

Similar Glossary Terms

- DOWNTIME

- Waste of Overproduction

- Lead Time

- Lean Maintenance

- 7 Wastes of Manufacturing

- Material Flow

- WIP (Work in Progress)

- Cellular Manufacturing

- Lean Manufacturing Process