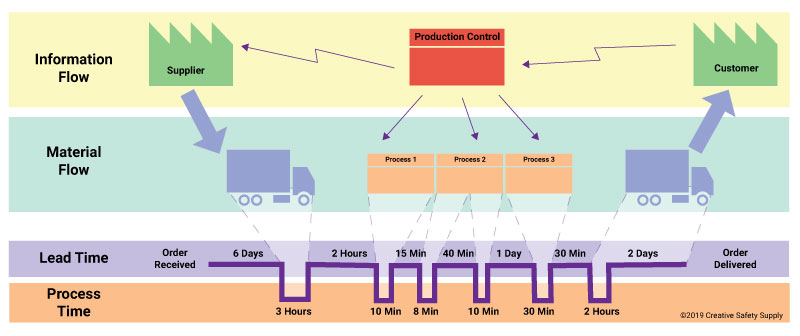

At the nucleus of Lean thinking is the focus on creating great value for customers while eliminating waste in the process. The stream of activities within an organization that creates this value for customers is often referred to as the value stream. Value stream mapping is a Lean tool used to assess the current state of work processes from start to finish. It is noteworthy because it shows both material flow and information flow, the latter of which is often left out of process maps. By showing information flow, people can get a better understanding of the current state and any potential problems that are occurring.

Value-stream maps are often hand-drawn and include a diagram of materials moving through parts of the workplace. These maps often include information about how long tasks take and how often orders for materials are placed.

At the bottom of the value-stream map, users draw a line representing total lead time. Beneath the line, waste, non-value-added activities, and value-added activities are drawn to demonstrate how much time is spent on each. This can help a business start to see where improvements can be made to reduce lead time.

The main objectives of current state value stream mapping are:

Show a holistic view of the entire current system.

Show a holistic view of the entire current system.- Indicate waste and its causes throughout a process.

- Identify areas where improvement is possible within a process.

- Provide a common picture that may be useful when discussing a process and other issues relating to it.

Once a current state value-stream map has been completed, users move on to future state value stream mapping to indicate where the process will ideally be in the not-too-distant future.

The objectives of future value stream mapping are:

- Provide organizations with a detailed visual description of a redesigned value stream.

- Force organizations to adopt best practices in creating a vision of the ideal Lean value stream.

- Assist organizations in quantifying the potential of improving not only their products or process, but also their services.

- Serve as communication tool for the future state of the process.

Once this value stream mapping has been completed, improvement plans can be developed and enacted to make appropriate adjustments.

Similar Glossary Terms

- Process Mapping

- Material Flow

- Yamazumi Chart

- Spaghetti Diagram

- Continuous Improvement

- Flowchart

- SIPOC Diagram

- Quality Engineering

- A3 Reporting