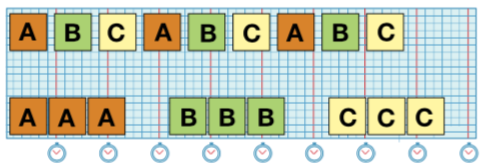

One-piece flow, sometimes called continuous flow or single-piece flow, is a production method used instead of traditional mass production. In mass production, materials move through the manufacturing process in batches which can be highly inefficient. In one-piece flow, a product is completed before the next one is started typically used in Lean organizations and will help businesses achieve Just-in-Time production.

Simply speaking, one-piece flow means parts are moved through the facility with little or no waiting time and arts are moved though operations efficiently. While this method of production may not seem intuitive, it is actually faster than performing Step 1 of a process on 100 products at once before moving on to Step 2. In mass production, it takes time to switch tasks or move products as a group. One-piece flow is generally more efficient, limits the amount of work in process, and prevents bottlenecks. The concept of one-piece flow is to only process and produce what the customer wants, effectively working to reduce the risk of excess production.

Setting up a workplace for one-piece flow production can require some planning and rearranging of workstations. Each step in the process should be placed next to the subsequent step to reduce motion and machines are placed in a logical order according to the production process. A Lean layout uses the principles of 5S to create a workspace that is easy to work in and follows the steps of productions. Takt time should be calculated to ensure cycle times are less than or equal to the takt time, and if a pull system is not already being utilized, it should be introduced into the workplace.

Adapting the one-piece flow mindset will help an organization avoid overproduction, reduce lead times, and scale down the amount of work in progress (WIP) materials on hand. Reducing inventory will cut down on storage wastes and can free up valuable space in the facility. The flow will create a consistency within production while standardizing work and helping a business achieve Overall Equipment Effectiveness. Additionally, a one-piece flow will make the manufacturing process more flexible, reduce the chance of defective process, and can even ensure a safer work environment.

Similar Glossary Terms

- Material Flow

- Cellular Manufacturing

- Waste of Overproduction

- Cycle Time

- DOWNTIME

- Just-in-Time Production

- Process Flow

- Changeover

- Standard Work