World Class Manufacturing is a set of concepts, policies, techniques, and principles for operating and managing a manufacturing company. The concept of World Class Manufacturing is based on the positive results achieved by Japanese manufacturing companies after World War II. A common definition of World Class Manufacturing is when United States’ companies began implementing Lean concepts in order to stay competitive in global markets. In order for companies to compete on the world stage, businesses will need to focus on producing quality products and services, delivering on time, and running operations at the lowest quality possible. Adopting the manufacturing processes will help managers focus on continual improvement in quality, cost, lead time, flexibility, and customer service.

World Class Manufacturing is a process-driven approach that generally involves implementing the following philosophies and techniques:

- Make-to-order

- Streamlined flow

- Small lot sizes

- Families of parts

- Doing it right the first time

- Cellular manufacturing

- Total preventive maintenance

- Quick changeover

- Zero Defects

- Just-in-time production

- Variability reduction

- Employee involvement

- Cross-functional teams (quality control circles)

- Multi-skilled employees

- Visual signals

- Statistical process control

To achieve world-class status, companies must change procedures and concepts in order to optimize their processes. This will lead to reconstructing relationships with suppliers, purchasers, producers, and customers.

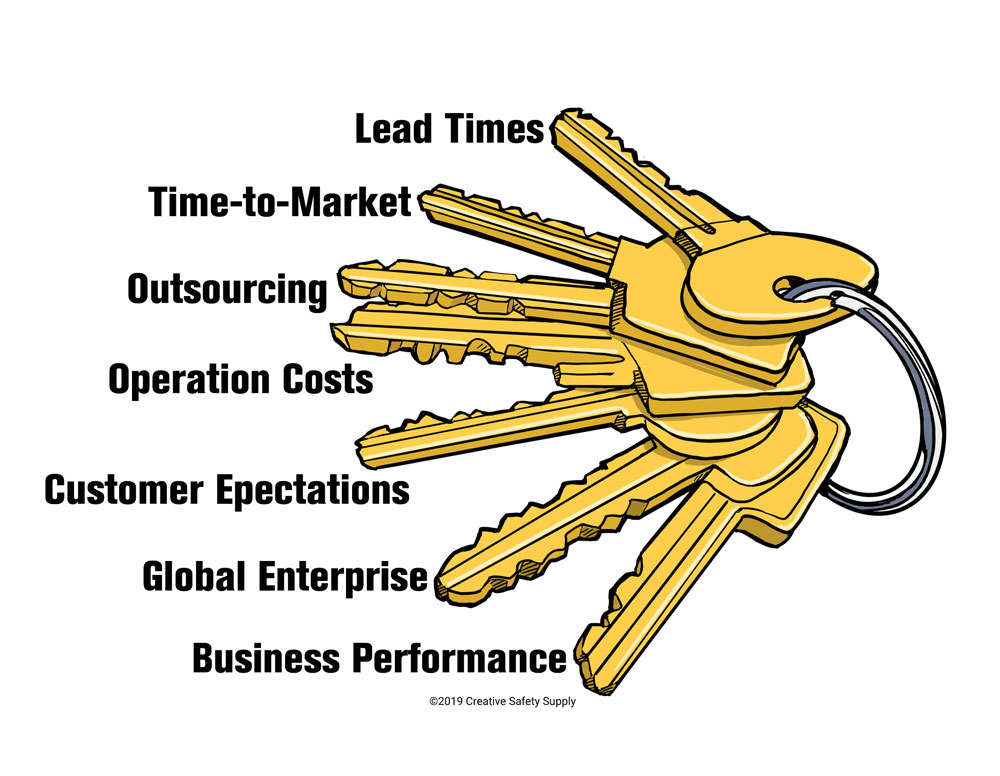

There are seven keys to becoming a world-class manufacturer:

There are seven keys to becoming a world-class manufacturer:

- Reduce lead times

- Speed time-to-market

- Streamline outsourcing processes

- Cut operations costs

- Exceed customer expectations

- Manage the global enterprise

- Improve business performance visibility

Companies using World Class Manufacturing strategies focus on continuously improving operations, eliminating waste, and creating Lean organizations, which often results in higher productivity. These companies also focus on setting new standards for speed from order capture through delivery without the heavy dependence on inventory. Combining the philosophies of World Class Manufacturing with the tools of Lean will help businesses achieve success and a reduction in waste. Sequential methods of performing work are being replaced with concurrent methods to compress time, and functional and hierarchical divisions of duties are being replaced by team-driven activities.