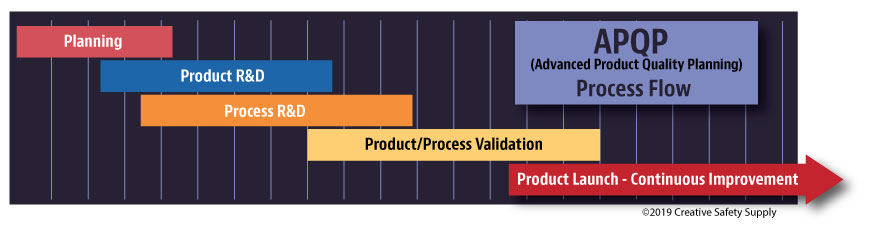

This is an acronym for a process and framework that was developed by the automotive industry meaning Advanced Product Quality Planning. The goal of APQP is to focus on the voice of the customer and to ensure the product created and manufactured will satisfy the customer requirements. The following are the five phases that go into implementing APQP:

- Phase 1: Product Planning and Quality Program Definition – The planning in this stage focuses on understanding the connection between the customer’s needs and wants with product expectations. This step of the process will aide in gathering relevant data to identify what the customer’s want and how to use that to determine the product’s characteristics. A list of preliminary characteristics and design/reliability of goals should be established in this step. Properly executing this step will create a solid foundation for the rest of the phases.

- Phase 2: Product Design and Development – The design and development of the product is the focus of this step. It includes designing specific features, completing the design review, defining material specifications and equipment requirements, and establishing control plans for prototype creation. This would also be the optimal phase to complete a Design Failure Mode and Effect Analysis (DFMEA).

- Phase 3: Process Design and Development: The third phase is all about planning the manufacturing process for producing the product. Manufacturing techniques should be explored, and measurement methods should be implemented. Ultimately, the goal is to develop a production process that works with the product specifications and production costs in mind. The manufacturing process should be able to keep up with consumer demands while operating efficiently. This phase is ideal for using Process Flow Charts and to complete a Process Failure Mode and Effects Analysis (PFMEA).

- Phase 4: Validation of Product and Process: This is the phase for testing the manufacturing process, ensuring it is capable of producing a quality product and can meet the necessary volume of production. Many tools can be introduced in this phase including Statistical Process Control (SPC), Measurement Systems Analysis (MSA), and Process Capability Studies. The Production Part Approval Process (PPAP) is ready to be submitted and once approved, production begins upon approval.

- Phase 5: Production Launch, Assessments, and Continuous Improvement: In this final phase APQP, evaluating processes after a full-scale launch should be emphasized. Customer feedback should be collected and assessed and data relevant to process efficiency should be used to plan future process improvement planning and activities.

The optimal and desired outcomes of using the structure of APQP are an improved manufacturing process, an improved quality of product, improved customer service, and improved customer satisfaction.