Resources

Regulations & Compliance Articles

OSHA Floor Marking Requirements You Should Know

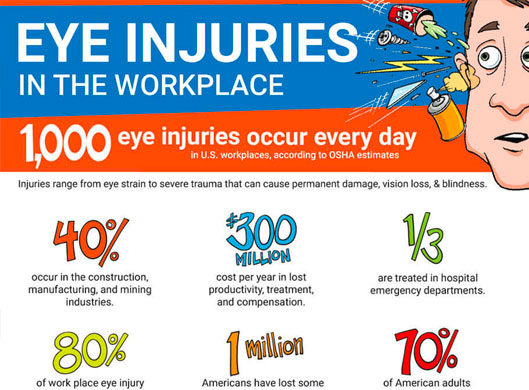

Figuring out OSHA floor marking guidelines can be puzzling without hours of research. To help you save time and get back to what’s important, we’ve compiled a guide on OSHA floor marking that focuses on the key objectives and ensures compliance. …

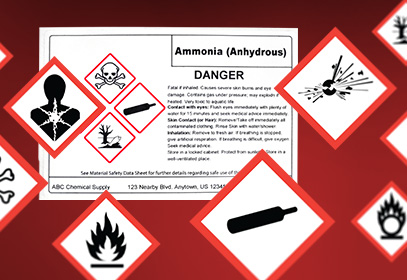

Ammonia Pipe Marking Standards | IIAR Requirements

Because ammonia is harmful to human health any pipes carrying ammonia-based substances must have more specific labeling than those under the ANSI/ASME standards. …

Marine Pipe Marking | ISO/DIS 14726

Since marine environments are required to carry fresh water along with gases, waste media, and fire-fighting chemicals, sea-faring vessels must comply with additional pipe marking color codes. This extra effort put into pipe markings for sea-faring vessels provides workers and first responders with the information they need regarding the unique contents of those pipes. …

Medical Substance Pipe Marking | NFPA99/CGA C-9

Substances used for medical purposes have their own standards and best practices as well. Since chemical substances used in hospitals are primarily gases, which are highly flammable, the National Fire Prevention Association (NFPA) is the entity that regulates and sets safety standards. …

Water Treatment Pipe Marking

In water treatment facilities, proper pipe marking is essential for maintaining safety, efficiency, and regulatory compliance …

Handling Hazardous Materials Safely

A workplace with the involvement of hazardous materials is a high risk ground. Investing in proper safety procedures is a sufficient way to avoid such risks. …

OSHA Compliance: What You Need to Know

OSHA is a federal agency that works on observing healthy working conditions and practices for labor workers. Learn more about OSHA and how it can benefit you. …

Introduction to Shipping Container Labeling

Shipping container labels convey crucial information throughout the shipping process, contributing significantly to the safety and efficiency of the industry. …

Labeling Practices for Power Generation Facilities

The power generation sector faces distinctive challenges, with hazards ranging from electrocution to arc flashes. Despite these risks, it remains one of the safer sectors due to stringent safety measures and regulations. Power facilities also incorporate redundancies to prevent outages, emphasizing the need for clear communication through labels, signs, and visual tools. …

A Brief Overview of Key Agricultural Labeling Requirements

Whether you operate a commercial farm or you are an employee at a small agricultural facility, it is important that you know all the rules and regulations that you need to follow, including proper labeling. …

A Simple Guide to Transportation Industry Labeling Strategies

Make sure you understand the labeling requirements before shipping any hazardous materials with this simple guide. …

NFPA 855: The Installation of Stationary Energy Storage Systems

NFPA 855 is an essential standard to follow to maintain worker safety while around stationary energy storage systems. …

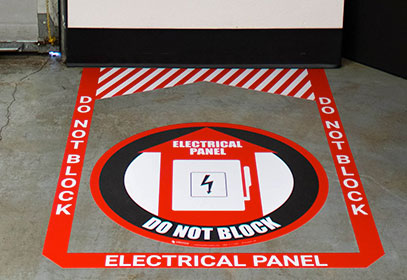

Floor Marking for Electrical Panel Compliance

Meet OSHA requirements for electrical panel clearance with floor markings! Creative Safety Supply offers a wide selection of floor signs and floor tapes for breaker panels. …

ISO 45003: Understanding Psychosocial Risks within the Workplace

Learn all about ISO 45003:2021 Occupational health and safety management — Psychological health and safety at work — Guidelines for managing psychosocial risks. …

ISO 31000:2018 – Risk Management

Explore the ISO 31000 risk management guidelines in this article! The principles, framework and process will be gone over in depth. …

Understanding OSHA/ANSI First Aid Kit Requirements

Everything you need to know about first aid kits, where they go, their contents, and why OSHA and ANSI requires them in every workplace. …

OSHA Construction Safety

Construction safety is all about picking out the right PPE, enforcing OSHA regulations, following consensus standards, and creating trust between you and your workers. …

Improving Workplace Electrical Safety

Choosing to improve worker knowledge and equipment for electrical safety creates a much safer workplace and improves overall productivity. …

NFPA 25: Standards for Fire Protection Systems

Learn about the updates made to NFPA 25 in 2020 as well as the essential components of fire protection and prevention systems that keep employees safe. …

How to Practice Social Distancing in Manufacturing Facilities

Social distancing and other protective measures have become a staple in occupational health and safety efforts due to COVID-19. New Social distancing guidelines from OSHA. …

OSHA Respiratory Protection Standard (29 CFR 1910.134)

Respiratory protection is essential where toxic substances are present, without PPE employees may suffer from long lasting injury or illness and even death.got …

Understanding Risk Assessments in the Workplace

Risk management relies on specific principles, a framework, and a process to work together in integrating a successful risk management and risk assessment program. …

Understanding the OSHA 300 Log and Other Incident Paperwork

The OSHA 300 log, 300A, and 301 forms are required by law if a company meets certain criteria. These forms enable the recognition of hazards that need to be eliminated. …

Fall Protection in the Workplace: OSHA’s Guidelines

Falls are among the leading causes of work-related injuries. Learn about the fall arrest equipment you need and best practices for a fall protection program in your workplace. …

Returning to Work Safely

As restrictions are lifted and your employees come back to work, make sure you continue to reduce the spread of COVID-19 by implementing these health and safety best practices. …

Floor Marking for Social Distancing

Using floor marking materials such as signs, tape, and other visual reminders is a highly effective way to implement social distancing and reduce the spread of illness in your facility. …

OSHA's Guidelines to Protecting Employees from Coronavirus

Learn which OSHA standards apply to preventing exposure to illness in the workplace, how to determine level of risk, and which controls to implement to protect your workers. …

Workplace Safety Inspections & Audits

Safety inspections and safety audits are two different methods of continuously improving health and safety in the workplace. Find out which one you need for effective safety management. …

Quality, Health, Safety, Environment (QHSE) Management Systems

Quality, Health, Safety, Environment (QHSE) management systems help businesses achieve three main objectives: enhanced quality, worker safety, and environmental sustainability. …

Guide to ANSI/ISEA Z358.1

ANSI/ISEA Z358.1 is the OSHA-enforced standard for eyewash stations and other equipment used to treat the eyes, face, and body of workers who have been exposed to hazardous materials. …

OSHA Incident Rates (Calculators + Formulas)

Calculating the OSHA Incident Rate and other safety rates is a useful tool for businesses to evaluate the frequency of onsite injuries and illnesses. The lower the rate, the safer the company. …

Safety Data Sheets (SDS)

Safety Data Sheets contain crucial information about the classifications and associated hazards of a chemical. They follow a standardized 16-section format and are required for any facility that handles, stores, or transports chemicals. …

Fire Safety in the Workplace

Fire safety is essential in every workplace. These are the principles that will help your facility prepare for fires and prevent them from occurring in the first place. …

National Electrical Code (NEC)

The National Electrical Code (NEC) is the ANSI/NFPA-approved standard for safe electrical installation. The NEC is revised once every three years, with the most recent changes in 2017. …

Mine Safety & Health [Expert Advice]

Miners face many hazards that put their safety at risk. By adhering to MSHA standards and providing training and appropriate equipment, employers can enhance mining safety. …

Title 49: Shipping Hazardous Materials

CFR 49 notes the procedure for transporting hazardous materials safely in compliance with the HMR. Learn more about this important regulation. …

What is Heat Stress?

Are your workers at risk for heat stress? Learn how to prevent this illness and the best plan of action. …

Quality Management Systems (ISO 9001:2015)

ISO 9001: 2015 is a standard that outlines and defines requirements for a quality management systems. This QMS certification allows companies to demonstrate to clients that they take quality and efficiency seriously. …

Food Security

With the 2011 passage of the Food Safety Modernization Act, considerable attention has been focused on the purity of our foods from the perspective of accidental contamination. …

Arc Flash Label Requirements [2018 Updates]

Arc flash hazard labels must be placed on any piece of electrical equipment where workers might need to perform work while the equipment is still energized. …

NFPA 99: Understanding the Health Care Facilities Code

NFPA 99 standards are built specifically to ensure safety from fire danger in healthcare facilities. Learn how to stay in compliance and protect your facility from fire hazards with this overview of the NFPA 99. …

A Quick Guide to Underground Utility Labeling

Underground utility labeling is an essential ingredient to every project that involves construction. This article outlines the step-by-step process of getting your site inspected for utilities, and how to label underground lines safely and accurately. …

Your Guide to Pipe Labeling Standards

If you are looking to implement or update a pipe marking strategy for your facility it is important to gathering as much information as possible. Read More... …

OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]

OSHA regulations require businesses to follow one of two safety sign standards to remain in compliance: ANSI 1967 and ANSI 2011. Take a look at these two styles and pick the one that best meets your needs. …

What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

Hazcom is designed to help employees to quickly identify hazardous chemicals. Learn more beneficial information about Hazcom. …

NFPA 70E [Workplace Electrical Safety]

NFPA 70E was created to help prevent injuries to workers in energized environments. If you’re working with live energy, you need to know this safety standard to stay OSHA compliant. …

A Guide to Pipe Marking Standards

For most industries, abiding by ASME/ANSI pipe marking standards is sufficient for staying safe and OSHA compliant. Some workplaces, though, are required to comply to more unique pipe marking standards due to the nature of the substance the pipes contain. …

SVEP – Severe Violator Enhancement Program

OSHA’s Severe Violator Enhancement Program (SVEP) was created to help ensure companies actually improve safety practices instead of just paying fines for violations. Learn how to avoid getting this designation by improving your workplace safety protocols and become a safe, efficient facility. …

ANSI TIA 606-B Cable Labeling Standards

ANSI TIA 606-B Cable Labeling Standards are a unified labeling method for the wires used in computer systems. These standards help businesses record data and keep their IT environments organized. Get to know these standards; they’ll help your business run more efficiently. …

Waste Water Treatment Labeling

Waste water treatment labeling ensures that all water and flow is accurately labeled. keeping employees safe from contaminated water. …

Lean Healthcare (Principles for Improvement)

Implementing lean healthcare in the medical field will lead to improvement in overall performance and patient satisfaction. …

Arc Flash Labeling (Updated)

Arc Flashes are one of the most dangerous accidents that can happen in a facility. Learn how to keep your facility safe and incident-free through proper labeling. …

Compliance Audit

Compliance audits are intended to help improve safety both for employees of the company, and for the community as a whole. Learn more about compliance audits how to prepare for them. …

Hazardous Materials Identification System (HMIS Labels)

Having a complete understanding of the Hazardous Materials Identification System (HMIS) is essential to keeping your employees safe when working with chemicals. …

Occupational Safety and Health Administration

Get answers to the most common questions regarding Occupational Safety and Health Administration (OSHA). …

HAZWOPER [OSHA Hazardous Waste Standard]

Crucial training for anyone who works with or near hazardous waste, the HAZWOPER standard seeks to keep workers safe and prevent environmental catastrophe. …

OSHA Card [Program Requirements + Benefits]

The term OSHA Card refers to a type of certification that is issued from OSHA after completing authorized training that they provide. …

Metal-Detectable Labels for FDA Food Labeling Compliance

Accidental contamination is a major worry in the food industry, and while it’s impossible to completely rule out all contamination, metal detectable labels help eliminate a significant danger. …

Short-Term Exposure Limit

Short-term exposure limits are a guideline that employers can use for how long an employee can be exposed to certain chemicals before their safety is compromised. Find out more... …

Safety Audit

In a safety audit, information is gathered about one or more aspects of the workplace in order to evaluate the risk levels for health or safety issues including efficiency, reliability, and effectiveness of their health and safety systems. …

Planned Maintenance

Planned maintenance, also known as planned preventative maintenance or scheduled maintenance, is an activity where a company will schedule work done in order to avoid outages. …

ANSI S3.19 – Noise Reduction

In most facilities there is no way to eliminate dangerous levels of noise, so it becomes necessary to wear hearing protection. Hearing protection is regulated by ANSI S3.19 standards. …

Visual Factories

Visual factories use signs, posters, charts, labels and floor marking to provide information that improves efficiency, safety and productivity in the workplace. This is a fairly simple concept that yields excellent results. …

OSHA 10-Hour Card [Training Requirements]

The OSHA 10 Hour Training program teaches those in attendance all about workplace hazards, the rights and responsibilities of employees and employers, workplace safety, and more. …

NIST Certification / Calibration

NIST is a standards laboratory that is part of the U.S. Department of Commerce that certifies that the equipment used by labs or manufacturing facilities is properly calibrated according to the industry standards in place. …

ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]

ANSI Z87.1 focuses on safety glasses and helps employers and employees make decisions that can help protect people’s eyes and face from a variety of threats. …

Hazard and Operability (HAZOP Analysis)

When done properly, the HAZOP process will identify potential design or process flaws that were not discovered in the past. …

OSHA General Duty Clause

The OSHA General Duty Clause is in place to require that employers provide employees with a workplace free from any recognizable hazards that could put them at risk of death or serious injury. …

Ammonia Refrigeration

When using ammonia refrigeration, or ammonia for anything in the workplace, there are a variety of OSHA regulations that need to be followed. …

Fire Prevention in the Workplace [OSHA 1910.39]

Fire prevention safety is important for all employees and workplaces. This article explains fire prevention standards and provides helpful tips. …

ANSI Color Codes for Pipe Marking

When following the ANSI A13.1 standards, the most important thing is to understand the six most common color schemes. …

OSHA Ear Protection Requirements (Standards for Hearing Safety)

Many people don't think about hearing protection when we talk about safety, but hearing injuries are one of the most common types of injuries that occur in the work place. …

Typical Lockout Tagout Procedures

Find out how to use lockout tagout procedures for different kinds of energy including electrical, chemical, and pneumatic. …

GHS Label Information

A closer look at OSHA’s Hazard Communication Standard—1900.1200—and how it applies to your facility. …

Confined Space Hazards

When is it safe to work in a confined space? Get the details in this article. …

Safety Colors (OSHA Guidelines and Color Codes)

Using colors strategically makes communication in your facility more effective. Get the details about common color codes. …

ANSI Z535 [Updated Guide to Safety Signs & Labels]

An in-depth look at ANSI’s standard for safety signs and labels in the workplace. …

Washington State – Accident Prevention Program

Find out the basic requirements of an accident prevention program. Then learn how to implement or improve one. …

Valve Tags: Guide for Pipe Identification

Tips and recommendations for labeling the valves on your pipe system. …

Arc Flash Software helps improve Arc Flash Safety

A review of common software programs that will help you reduce arc flash hazards. …

Aisle Marking Tape – 5 Strongest Tapes You have Ever Seen!

Learn the requirements for marking aisles and the best methods for doing so. …

The Definitive Guide to Globally Harmonized System (GHS) Labeling

Implementing GHS has been an evolving process for many companies. Here's what you need to know. …

Floor Marking for Electrical Panel Compliance

Make sure you are meeting OSHA requirements for marking around electrical panels. …

Material Safety Data Sheets [How-To Guide for Upgrading to SDS]

Learn the difference between the old material safety data sheets and the new GHS/HazCom safety data sheets. …

Pipe Color Codes - ANSI/ASME A13.1

The ANSI/ASME A13.1 pipe marking color code explained. …

OSHA Facts

Everything you need to know about the Occupational Safety and Health Administration. …

What are ANSI standards?

The American National Standards Institute makes guidelines that could impact your workplace. …

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it. …

OSHA Floor Marking

Find out what OSHA has to say about marking your facility's floors. …

Process Safety Management

PSM is an OSHA standard developed for companies that handle hazardous chemicals. …

Floor marking comprehensive research, education and training

Everything you need to know about marking your facility’s floors. Types of markings, practical tips, and more. …

Regulations & Compliance Questions and Answers

What are the Most Crucial Workplace Regulations in the US?

All businesses are required to follow workplace regulations, aligning with fair practices and considering the safety and wellbeing of employees. In this article, we discuss some examples of the most important workplace regulations to be aware of. Occupational Safety and Health Administration (OSHA) OSHA is the main regulatory body responsible for safe working environments, enforcing regulations that… …

How do I use the IMDS?

In an era where environmental sustainability and compliance are paramount, the IMDS, or International Material Data System, emerges as a critical tool for industries. Understanding how to effectively use this platform is essential for companies aiming to meet regulatory standards and uphold their commitment to environmental responsibility. In this article, we'll explore what the IMDS… …

Why was the IMDS Invented?

In the complex landscape of modern industries, managing the environmental impact of products is a critical concern. This is where the IMDS, or International Material Data System, steps in as a crucial tool. In this article, we'll explore what the IMDS is, why it was invented, and how it serves as a linchpin in ensuring… …

How can I Improve Safety and Compliance with Valve Tags?

The proper use of valve tags is an essential part of safety and compliance within the industrial sector. Being a simple yet effective tool which can implement safety protocols across various industries, this article discusses various examples of how valve tags should be used effectively. Sequential numbering When valve tags are set up, sequential numbering is a… …

What is ATSDR?

ATSDR stands for the Agency for Toxic Substances. It is a public health agency that is a part of the US Department of Health and Human Services. This agency has a primary focus on helping to minimize the health risks for humans that are associated with exposure to hazardous substances. This agency does work with… …

What Does STEL Stand For?

STEL stands for Short-Term Exposure Limit. This is the amount, or concentration, of a particular substance that someone can be exposed to continuously for a 15-minute length of time without being at risk of harm. The term is used throughout many different industries, especially those that regularly work with different substances that can be harmful… …

What Does TLV Stand For?

TLV stands for Threshold Limit Value and is a term that is used to describe the level of a particular thing that a worker can be exposed to during their shift without experiencing any type of adverse effects. This term got its official start from the American Conference of Governmental Industrial Hygienists (ACGIH). While this… …

What Does ASHRAE Stand For?

ASHRAE stands for the American Society of Heating, Refrigerating, and Air-Conditioning Engineers. This is a professional organization that has been around since 1895. While it started in America and with a focus on American engineers, the association has grown to have more than 50,000 embers that come from more than 130 different countries. This global group… …

What are Examples of Engineering Controls?

When looking at the hierarchy of controls, you will see that engineering controls are the middle (or third) option. To put it simply, engineering controls are when people (or equipment) are physically separated from the hazard. One of the simplest examples of this would be when a machine’s motion creates a location where someone would be… …

What Does IAQ Stand For?

IAQ stands for Indoor Air Quality. It is a concept that is used to determine how pure the air is in and around buildings and other structures. This is an especially important topic for facilities that use any type of hazardous chemicals or have work that is done in confined spaces. When air is not… …

What is an ESO?

The acronym ESO stands for European Standardization Organizations. There are currently three committees that hold this title in Europe and those are: CEN – The European Committee for Standardization, or Comité Européen de Normilisation as the acronym is intended, prioritizes the health of the European Single Market and global trading while also providing the necessary… …

What is the European Standard EN 50110?

The 50110 European electrical standard, ratified by the three ESOs in Europe, covers all general requirements for electrical activity that deal with working on, with, or near electrical installations at varying different levels of voltages. To put it simply, the standard essentially goes over all aspects of safety and installation when electrical risks are present… …

What is the NEN 3140 Standard?

The NEN 3140 Operation of Electrical Installations – Low Voltage standard is a Dutch standard that works in tandem with EN 50110. Bundled together, both the NEN 3140 and NEN-EN 50110 standards are referred to as “Operation of electrical installations 1998” and cover both low voltage and high voltage working conditions. Overall, NEN 3140 covers… …

What is the difference between NFPA 70E and EN 50110?

The differences between the United State’s NFPA 70E standard and Europe’s EN 50110 standard are enough to warrant a comparison of the two. The following are a handful of significant differences between the two electrical safety standards: Training requirements and personnel responsibilities NFPA 70E – There are two different classifications of personnel described in this… …

What is NIST?

NIST stands for the National Institute of Standards and Technology, it was founded in 1901 by the U.S. Department of Commerce. The National Institute of Standards and Technology aims to promote innovation and industrial competitiveness within the United States through measurement science, standards, and other technology. To do this, NIST activity is broken up into… …

What does HVAC stand for?

HVAC stands for heating, ventilation, and air conditioning. These are essential components in any sort of industry as they not only provide comfort to the employer, employees, and visitors, but they also mediate the indoor air quality (IAQ). Without proper attention, the IAQ conditions can become dangerous due to poor ventilation of things such as… …

What does PEL stand for?

PEL stands for “Permissible Exposure Limit.” These limits are established by OSHA to protect employees who work in environments that may be hazardous—for example, environments that include loud noises, chemical substances, or physical agents. PELs establish a certain threshold for exposure to these factors to help ensure safety. Once a worker’s exposure surpasses that threshold,… …

What is TSCA?

TSCA stands for ‘Toxic Substances Control Act.’ This is a law passed by the US Congress in 1976 and is a part of the Environmental Protection Act (EPA). The law regulates the introduction of any new or existing chemicals into a given environment. When the law was originally put into place all chemicals that were… …

What does NIOSH stand for?

NIOSH stands for the National Institute for Occupational Safety and Health. This is a US federal agency that is responsible for conducting various types of research related to work-related injuries, illnesses, and other related issues. Based on the research they perform they will then make recommendations on how to prevent these types of problems from… …

What does GMP stand for?

GMP stands for Good Manufacturing Practices. Good manufacturing practices are used to provide guidelines to companies that manufacture products for a variety of different industries. These industries include food services, beverages, cosmetics, pharmaceutical products, dietary supplements, medical devices, and more. Due to the fact that these types of products can have such a direct and… …

What is IMDS?

Suppliers in the automotive supply chain record material data into an online data repository called the IMDS, or the International Material Data System. Every part in every car produced by every participating auto manufacturer will have an entry on the database listing size, weight, and materials, and customers are able to follow parts back to… …

![Mine Safety & Health [Expert Advice]](https://www.creativesafetysupply.com/content/images/articles/mining-safety-th.jpg)

![Arc Flash Label Requirements [2018 Updates]](https://www.creativesafetysupply.com/content/images/articles/arc-flash-labels-th.jpg)

![OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]](https://www.creativesafetysupply.com/content/images/articles/ansi-sign-headers-th.jpg)

![NFPA 70E [Workplace Electrical Safety]](https://www.creativesafetysupply.com/content/images/articles/nfpa-70e-th.jpg)

![HAZWOPER [OSHA Hazardous Waste Standard]](https://www.creativesafetysupply.com/content/images/articles/hazwoper-thumb.jpg)

![OSHA Card [Program Requirements + Benefits]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-osha-10-card.jpg)

![ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-safety-glasses.jpg)

![Fire Prevention in the Workplace [OSHA 1910.39]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-fire-prevention.jpg)

![ANSI Z535 [Updated Guide to Safety Signs & Labels]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-z535.jpg)

![Material Safety Data Sheets [How-To Guide for Upgrading to SDS]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-msds-sds.jpg)

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)