In many work environments, hazardous chemicals are constantly present to allow the completion of different tasks. To help ensure those chemicals are able to be used safely for the facility, employees, and surrounding environment, a set of hazard communication standards have been established by OSHA.

The Hazard Communication Standards (HCS), or HAZCOM for short was made to make it faster and easier for people to get the information they need about specific chemicals. This is important in the event of a an issue as being able to take the right action and doing so quickly is critical for everyone's safety.

All companies that use hazardous chemicals need to prioritize hazard communication for the benefit of all employees, contractors, and anyone else working in the area.

Hazard Communication + The Globally Harmonized System (GHS)

HAZCOM requirements have been developed over the course of many years to help improve workplace safety. Today, the standards that are in place have been adopted by many countries around the world. In the United States, OSHA has aligned their communication standards with the Globally Harmonized System of Classification and Labeling of Chemicals, also known as GHS.

Having as many facilities around the world following the same type of communications is essential for keeping everyone safe at work. This is because harmonized standards such as the union between GHS and OSHA’s HAZCOM requirements allow people to move from one workplace to another without the need for significant retraining. This action can also prevent misunderstandings and other mistakes caused by mislabeling, or omitted information, from occurring, which could cause serious injuries or even fatalities.

OSHA Requirements: HAZCOM Standard (HCS)

OSHA has made following the HAZCOM standards mandatory for just about all types of businesses that exist in the United States. There are a number of different requirements that need to be followed in order to avoid citations.

Scope

OSHA identifies exactly which companies must incorporate these standards, and to what extent. Due to the nature of the standards, and the differences in types of facilities, only certain aspects will be applicable in each situation.

Chemical manufacturers and importers need to classify the specific hazards of all the chemicals that they produce or import. All of the employees who work with or around these chemicals also need to be informed about the risks associated with exposure.

In situations where employees are only responsible for transporting or storing chemicals, the requirements are less strict. This is because the containers holding the chemicals are never opened, which greatly reduces the overall risk associated with working with them. However, employees still must be trained sufficiently on how to respond to an accidental spill.

Written Program

Companies that have dangerous chemicals stored and/or used on site also need to create a written hazard communication program. This program needs to be customized to the specific facility and should include information such as:

- Chemicals - Identify which chemicals are used in the facility. This should include any chemicals that are present at any time, even if they aren't always being used.

- Safety Data Sheets - The program has to have safety data sheets (SDS) on each of the chemicals listed.

- Warnings - Warning information about all the chemicals present allow employees to quickly see the risks associated with exposure.

- Response Plans - Instructions on what should be done in the event of exposure or an accident. This should include details on what to do for anything ranging from basic skin exposure to a full chemical spill, or any other possible situation.

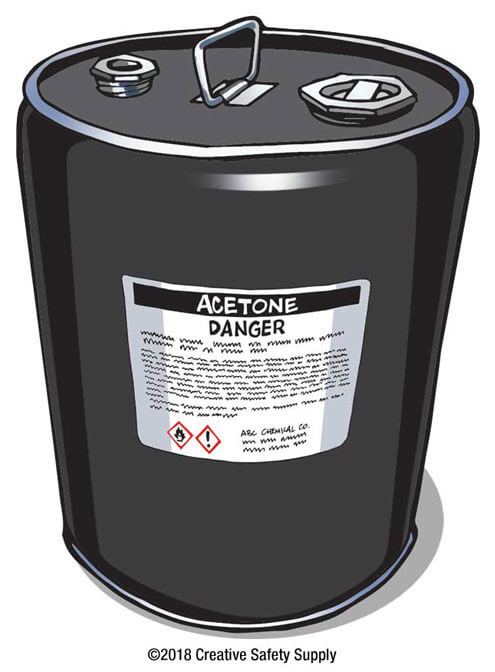

Compliant Hazard Labels

Any containers or machines that use chemicals need to be labeled with specific information about those chemicals. In America, these labels must be written in English with clear fonts and include any GHS pictograms or hazard symbols if necessary. Employers may add additional labels in other languages as appropriate for their work environment.

The labels can either be pre-printed and applied to the containers that are delivered to the facility or printed on an industrial label printer in the facility itself. The labels must be applied to the containers as soon as is reasonably possible.

HAZCOM Training

Having the information available in the facility is not sufficient for OSHA compliance. Facilities must also provide all employees with training that covers the safety hazards and responses necessary if there is a spill or other accident.

This training should also explain how to read warning labels, safety data sheets, and any other information that is on site and part of the hazardous communication standard. If there are any additions or changes to the type of chemicals used on site, employees should be trained on those specific chemicals prior to their arrival if possible.

Providing annual refresher training will also help to ensure the facility is kept as safe as possible. These annual trainings can be conducted as one large group or given to individual employees by their direct supervisors. Tracking the training as it is given is important for OSHA compliance as well.

HAZCOM Violations

In America, OSHA takes HAZCOM compliance very seriously. Violations of these standards are among the most commonly cited problems that OSHA issues against companies. OSHA is willing to help companies become compliant but when there are violations, they can come with serious penalties including the following:

- Financial fines

- Downtime & work disruption

- Negative press

- Damage to company reputation

- Increased inspections

What is an Example of a HAZCOM Violation?

Some of the more commonly cited hazard communication violations stem from storing enough information for employees to reference, whether that be in paper form or knowledge-wise. The following are some examples:

- Failing to complete a written hazard communication program

- Failing to maintain employee training opportunities

- Failing to label chemicals properly

- Failing to both have and maintain SDSs for all chemicals in the workplace

Mistakes such as these can be detrimental to business as well as foster a hazardous workplace for all employees. Avoid this by following OSHA’s standards.

Recent Hazard Communication Updates

For businesses operating in the United States, it is important to comply with OSHA's standards related to HAZCOM. OSHA works hard to make sure all companies have everything they need to remain in compliance, as this will help to improve workplace safety.

Companies that need to become compliant can find resources available from OSHA. They offer a variety of HAZCOM solutions, most of them free of charge, to help improve safety and ensure compliance with all applicable laws and regulations.

Making the effort necessary to become, or remain, compliant is not only important for avoiding penalties, but also for ensuring everyone in the facility is safe. Programs such as this one from OSHA have helped

to dramatically reduce the number of workplace accidents, injuries, and fatalities associated with exposure to chemicals over the years. Reducing or eliminating these issues helps to ensure that a facility is able to remain up and operational as much as possible, and reduces the expenses associated with an unsafe work environment.

Similar Articles

- Material Safety Data Sheets [How-To Guide for Upgrading to SDS]

- OSHA Facts [Updated Statistics 2019]

- OSHA Safety Sign Requirements [1910.145]

- Anhydrous Ammonia – Safety & Labeling

- Hazardous Materials Identification System (HMIS Labels)

- Occupational Safety and Health Administration

- GHS Label Information

- OSHA Ear Protection Requirements (Standards for Hearing Safety)

- GHS: The Globally Harmonized System for Labeling [Updated 2019]