Resources

Workplace Safety Articles

Abandoned Pipe Marking Requirements Under ANSI/AMSE A13.1

Explore the guidelines of the ANSI/ASME A13.1 standard for identifying abandoned piping left in place. Learn why it's important to designate the pipe's status.…

Understanding Canadian Pipe Marking Standards (CAN/CGSB-24.3-12) and Hazard Symbols

Learn CAN/CGSB-24.3-12 pipe marking standards, including color coding, legends, flow direction, and WHMIS pictograms to ensure effective & compliant labeling.…

A Comprehensive Guide to Rotating Shifts

Rotating shifts help businesses maintain 24/7 coverage while supporting employee needs. This guide explains what rotating schedules are, the most common types, their benefits and drawbacks, and practical tips for managing them effectively.…

OSHA Floor Marking Requirements You Should Know

Figuring out OSHA floor marking guidelines can be puzzling without hours of research. To help you save time and get back to what’s important, we’ve compiled a guide on OSHA floor marking that focuses on the key objectives and ensures compliance. …

What Causes Outlet Fires?

Explore the common causes of an outlet burning or catching fire, including faulty wiring, overloaded circuits, poorly grounded outlets, old outlets, and more.…

A Guide to Workplace Safety Signs

Workplace safety programs have many parts, all of which are important to keeping people safe on the job. Safety signs play a key role in many aspects of safety from notifying people of tripping hazards and PPE requirements to explaining arc flash and chemical hazards.…

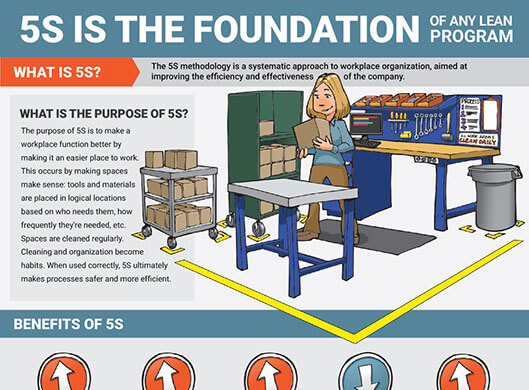

5 Lean Manufacturing Tools that Work

These five lean manufacturing tools are essential for making your lean journey a success.…

Safety Protocols for Construction Sites

To ensure the safety and functionality of construction workers, implementation of safety protocols are a requirement that should be exercised in a robust manner. …

Handling Hazardous Materials Safely

A workplace with the involvement of hazardous materials is a high risk ground. Investing in proper safety procedures is a sufficient way to avoid such risks. …

Ergonomics and Workplace - Everything You Need to Know

Develop an understanding about the importance of ergonomics in the workplace with this comprehensive guide. …

OSHA Compliance: What You Need to Know

OSHA is a federal agency that works on observing healthy working conditions and practices for labor workers. Learn more about OSHA and how it can benefit you. …

Lean Safety | Understanding the Lean 6S Methodology

Implementing lean safety can result in safer and more efficient working conditions that minimize errors and require fewer corrective measures. …

Pharmaceutical Labeling

Learn everything you need to know about pharmaceutical labeling, including the standards it follows, regulatory requirements, and how to create the labels that you need for your company. …

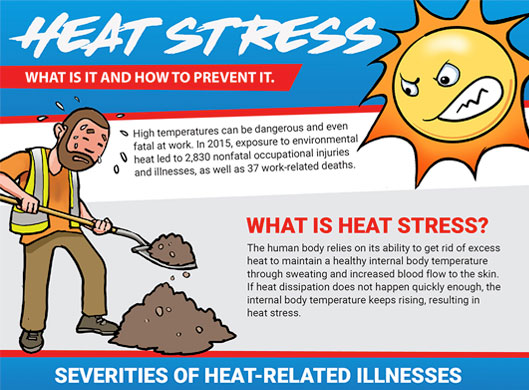

Heat Exhaustion and the Dangers of High Temperature Exposure

Learn to recognize the signs and symptoms of heat exhaustion and heat stroke. Heat induced illnesses can cause significant damage to the body and even result in death.…

ISO 45003: Understanding Psychosocial Risks within the Workplace

Learn all about ISO 45003:2021 Occupational health and safety management — Psychological health and safety at work — Guidelines for managing psychosocial risks.…

ISO 31000:2018 – Risk Management

Explore the ISO 31000 risk management guidelines in this article! The principles, framework and process will be gone over in depth.…

Understanding OSHA/ANSI First Aid Kit Requirements

Everything you need to know about first aid kits, where they go, their contents, and why OSHA and ANSI requires them in every workplace.…

Addressing Biohazard Safety in the Workplace

Biohazards consist of bacteria, virus, and fungi pathogens, as well as parasites. Remembering to provide the correct equipment, training, and visual communication is essential.…

OSHA Construction Safety

Construction safety is all about picking out the right PPE, enforcing OSHA regulations, following consensus standards, and creating trust between you and your workers. …

Improving Workplace Electrical Safety

Choosing to improve worker knowledge and equipment for electrical safety creates a much safer workplace and improves overall productivity.…

How to Practice Social Distancing in Manufacturing Facilities

Social distancing and other protective measures have become a staple in occupational health and safety efforts due to COVID-19. New Social distancing guidelines from OSHA.…

OSHA Respiratory Protection Standard (29 CFR 1910.134)

Respiratory protection is essential where toxic substances are present, without PPE employees may suffer from long lasting injury or illness and even death.got…

Understanding Risk Assessments in the Workplace

Risk management relies on specific principles, a framework, and a process to work together in integrating a successful risk management and risk assessment program.…

An Introduction to Industrial Hygiene

OSHA claims industrial hygiene is the science of anticipating, recognizing, evaluating, and controlling workplace conditions that may cause workers' injury or illness.…

Preparing the Workplace with Emergency Action Plans (EAP)

An emergency action plan is a written document required by OSHA that details procedures carried out by employees during the event of an emergency.…

Understanding the OSHA 300 Log and Other Incident Paperwork

The OSHA 300 log, 300A, and 301 forms are required by law if a company meets certain criteria. These forms enable the recognition of hazards that need to be eliminated.…

Keeping Operators Safe with Machine Guarding

Machine guards are essential for facilities where employees work in close proximity to hazardous moving parts. Properly safeguarding machines prevents severe injury and death.…

Staying Lean During a Pandemic

It’s important to stay focused on efficiency as the COVID-19 pandemic continues. Here are several Lean manufacturing techniques that can help your business continually improve, even during times of crisis.…

Fall Protection in the Workplace: OSHA’s Guidelines

Falls are among the leading causes of work-related injuries. Learn about the fall arrest equipment you need and best practices for a fall protection program in your workplace.…

Cleaning the Workplace During COVID-19

Using the 5S method to clean and organize your facility is more important than ever as the coronavirus pandemic continues to impact workplace safety. …

Job Hazard Analysis: Addressing Coronavirus Risk in Your Workplace

A Job Hazard Analysis (JHA) is an effective means of identifying and addressing safety hazards. JHAs can be used to address the risks of COVID-19 in your facility.…

Returning to Work Safely

As restrictions are lifted and your employees come back to work, make sure you continue to reduce the spread of COVID-19 by implementing these health and safety best practices. …

Floor Marking for Social Distancing

Using floor marking materials such as signs, tape, and other visual reminders is a highly effective way to implement social distancing and reduce the spread of illness in your facility.…

OSHA's Guidelines to Protecting Employees from Coronavirus

Learn which OSHA standards apply to preventing exposure to illness in the workplace, how to determine level of risk, and which controls to implement to protect your workers.…

Workplace Safety Inspections & Audits

Safety inspections and safety audits are two different methods of continuously improving health and safety in the workplace. Find out which one you need for effective safety management.…

Quality, Health, Safety, Environment (QHSE) Management Systems

Quality, Health, Safety, Environment (QHSE) management systems help businesses achieve three main objectives: enhanced quality, worker safety, and environmental sustainability. …

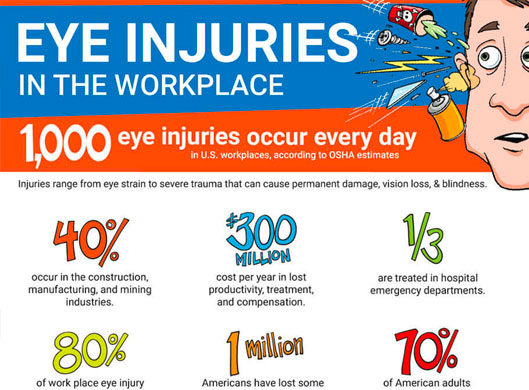

Guide to ANSI/ISEA Z358.1

ANSI/ISEA Z358.1 is the OSHA-enforced standard for eyewash stations and other equipment used to treat the eyes, face, and body of workers who have been exposed to hazardous materials.…

OSHA Incident Rates (Calculators + Formulas)

Calculating the OSHA Incident Rate and other safety rates is a useful tool for businesses to evaluate the frequency of onsite injuries and illnesses. The lower the rate, the safer the company.…

Safety Data Sheets (SDS)

Safety Data Sheets contain crucial information about the classifications and associated hazards of a chemical. They follow a standardized 16-section format and are required for any facility that handles, stores, or transports chemicals.…

Automated Guided Vehicle Lane Marking

AGVs exist in large facilities to help with consistency and safety. Used for manual labor, AGVs are able to reduce steps in processing to focus on other priorities.…

Fire Safety in the Workplace

Fire safety is essential in every workplace. These are the principles that will help your facility prepare for fires and prevent them from occurring in the first place.…

6S: Safety

Safety is the additional sixth step to the traditional 5S method. A company that implements 6S focuses on improving organization and efficiency, with an emphasis on safety throughout each step.…

Emergency Spill Cleanup & Containment

When a spill occurs at work, safety relies on a fast response. These are the steps to take and best practices for spill cleanup. …

Title 49: Shipping Hazardous Materials

CFR 49 notes the procedure for transporting hazardous materials safely in compliance with the HMR. Learn more about this important regulation.…

What is Heat Stress?

Are your workers at risk for heat stress? Learn how to prevent this illness and the best plan of action. …

Forklift Safety Procedures

Forklifts are powerful tools that have transformed the way industrial facilities work. With such a powerful tool comes the risk of injury. This article outlines how to increase forklift safety.…

Food Security

With the 2011 passage of the Food Safety Modernization Act, considerable attention has been focused on the purity of our foods from the perspective of accidental contamination. …

Behavior-Based Safety

Behavior-Based Safety, when used properly, can increase safety and improve employee engagement in safety programs. Learn how BBS can help you improve your safety program.…

NFPA 99: Understanding the Health Care Facilities Code

NFPA 99 standards are built specifically to ensure safety from fire danger in healthcare facilities. Learn how to stay in compliance and protect your facility from fire hazards with this overview of the NFPA 99.…

Safety Committee

Implementing a safety committee can help improve the overall safety of your company. Discussing safety concerns and resolving them will keep your employees safe.…

Electric Arc [Definition, Applications & Arc Flash]

Electrical arcs can be a serious hazard when not intended. When an electric arc is created in an uncontrolled environment, such as an arc flash, serious injury or death can occur. Learn more...…

Your Guide to Pipe Labeling Standards

If you are looking to implement or update a pipe marking strategy for your facility it is important to gathering as much information as possible. Read More...…

Catchy Safety Slogans for the Workplace

Catchy safety slogan signs are an interesting method that many companies use to keep employees and customers safe.…

Electrical Wire Colors

Electrical wire colors are essential to the safety of anyone working with electricity. Click here and learn more about electrical color standards.…

OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]

OSHA regulations require businesses to follow one of two safety sign standards to remain in compliance: ANSI 1967 and ANSI 2011. Take a look at these two styles and pick the one that best meets your needs.…

What is HAZCOM? (Hazard Communication Definition + OSHA Standards)

Hazcom is designed to help employees to quickly identify hazardous chemicals. Learn more beneficial information about Hazcom.…

What is a thermal printer? (direct transfer)

Thermal printers are essential to printing in an industrial setting. Learn about the two types of thermal printing to determine which one suits your facility’s needs. …

Tool Storage Ideas

Lean manufacturing emphasizes organization, but it can be difficult figuring out just how to get started. This article lays out some common and effective ways of getting organized quickly. …

Value Stream Mapping (VSM Analysis)

Value stream mapping (VSM) gives a comprehensive look at a business’s production process. Once a business has their process mapped out, it’s easy to identify the places where waste happens. …

SVEP – Severe Violator Enhancement Program

OSHA’s Severe Violator Enhancement Program (SVEP) was created to help ensure companies actually improve safety practices instead of just paying fines for violations. Learn how to avoid getting this designation by improving your workplace safety protocols and become a safe, efficient facility.…

Waste Water Treatment Labeling

Waste water treatment labeling ensures that all water and flow is accurately labeled. keeping employees safe from contaminated water.…

Neutral Wire Color

Since electricity is an essential component of virtually every facility, it’s important to know which wires are associated with what color, and at what voltage.…

Lean Healthcare (Principles for Improvement)

Implementing lean healthcare in the medical field will lead to improvement in overall performance and patient satisfaction.…

OSHA Accident Reports

All companies want to avoid accidents, but an unfortunate reality is that work-related injuries happen. How a company reacts to the incident is crucial. …

Floor Marking for Factories

Factories are busy, active environments with a lot happening at all times. Floor marking is a low-cost way of improving efficiency, safety, and organization.…

Arc Flash Labeling (Updated)

Arc Flashes are one of the most dangerous accidents that can happen in a facility. Learn how to keep your facility safe and incident-free through proper labeling. …

Floor Marking for Facility Safety

The best way to enhance safety is keeping workers informed, and floor markings are the most reliable, durable method of ensuring that everyone is aware of potential hazards.…

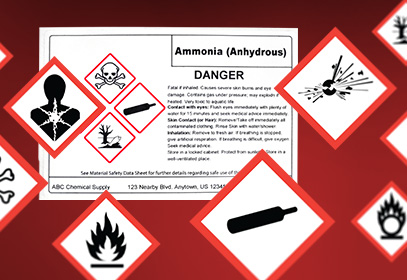

Anhydrous Ammonia – Safety & Labeling

Concentrated (or anhydrous) ammonia presents significant hazards to people and the environment. Here’s what you need to know to stay safe. …

Floor Marking for Door Openings

Every time a door opens, it presents a potential hazard to anyone on the opposite side. With careful floor marking, you can massively reduce this risk and prevent numerous injuries.…

Electrical Wiring (Wire Color Codes)

Proper electrical wiring is not the place for uncertainity. Fortunately, Wire Color Codes exist to protect you from harm, while ensuring that the lights stay on.…

Hazardous Materials Identification System (HMIS Labels)

Having a complete understanding of the Hazardous Materials Identification System (HMIS) is essential to keeping your employees safe when working with chemicals.…

Floor Marking for Fire Extinguishers

Use floor markings to make sure you can find the fire extinguisher and that it is not blocked in an emergency.…

Occupational Safety and Health Administration

Get answers to the most common questions regarding Occupational Safety and Health Administration (OSHA).…

Calculating Overall Equipment Effectiveness (OEE)

Are your lean and 5S efforts making a difference? Crunch the numbers on OEE to find out!…

Hazard Pictograms (GHS Symbols)

More than crude drawings, these nine illustrations protect millions of people throughout a variety of industries each and every day.…

HAZWOPER [OSHA Hazardous Waste Standard]

Crucial training for anyone who works with or near hazardous waste, the HAZWOPER standard seeks to keep workers safe and prevent environmental catastrophe.…

OSHA Card [Program Requirements + Benefits]

The term OSHA Card refers to a type of certification that is issued from OSHA after completing authorized training that they provide.…

Workplace Lifting Safety

Lifting heavy items is one of the leading causes of injury in the workplace. Save time and money by learning how to prevent lifting injuries.…

Crane Safety

Crane safety is essential when working within a construction area. Check out this article for important information and a crane safety checklist.…

Forklift Safety

Forklift safety injuries have been on the rise and its up to you to help fix it. Here are some forklift safety tips to help you get started.…

Job Safety Analysis

Job safety analysis is a great process to learn and understand to help identify safety hazards within the workplace. Learn more ›…

Creating a Visual Workplace

Creating a visual workplace can help improve efficiency and reduce workplace injuries. Check out these tips for creating a visual workplace.…

Warehouse Management

Proper warehouse management can dramatically improve both efficiency and safety. This article covers everything you need to know.…

The Five Whys (Root Cause Analysis)

Finding the root cause of a problem is imperative in problem solving. The "five whys" will help you find the root cause and prevent future issues.…

Hazardous Waste Disposal

Implementing proper hazardous waste disposal tools within the workplace is essential for keeping employees safe. Do you have these hazardous waste tools?…

Short-Term Exposure Limit

Short-term exposure limits are a guideline that employers can use for how long an employee can be exposed to certain chemicals before their safety is compromised. Find out more... …

ANSI S3.19 – Noise Reduction

In most facilities there is no way to eliminate dangerous levels of noise, so it becomes necessary to wear hearing protection. Hearing protection is regulated by ANSI S3.19 standards.…

Hard Hat Classes [OSHA & ANSI Standards]

Each hard hat class is designed specifically to help provide protection against certain types of hazards. Learn about hard hat classes to ensure the right hats are used to keep everyone safe.…

OSHA 10-Hour Card [Training Requirements]

The OSHA 10 Hour Training program teaches those in attendance all about workplace hazards, the rights and responsibilities of employees and employers, workplace safety, and more.…

ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]

ANSI Z87.1 focuses on safety glasses and helps employers and employees make decisions that can help protect people’s eyes and face from a variety of threats.…

Ammonia Refrigeration

When using ammonia refrigeration, or ammonia for anything in the workplace, there are a variety of OSHA regulations that need to be followed. …

ANSI Color Codes for Pipe Marking

When following the ANSI A13.1 standards, the most important thing is to understand the six most common color schemes. …

OSHA Ear Protection Requirements (Standards for Hearing Safety)

Many people don't think about hearing protection when we talk about safety, but hearing injuries are one of the most common types of injuries that occur in the work place.…

Floor Markings for Forklift Safety

Installing floor markings for forklift traffic can help improve safety and efficiency in warehouses and factories. Take these steps to keep employees safe.…

Floor Marking Ideas for Warehouses

Warehouse floors provide an opportunity for visual communication. Find out what floor signs, tapes, and shapes you can use.…

Labeling Electrical Conduits

Learn how to label electrical conduits so employees can quickly identify them.…

GHS Label Information

A closer look at OSHA’s Hazard Communication Standard—1900.1200—and how it applies to your facility.…

Types of Floor Marking

Many options exist for marking floors. Learn about floor tapes, virtual floors signs, and more.…

Confined Space Hazards

When is it safe to work in a confined space? Get the details in this article.…

Arc Flash PPE

Make sure everyone knows what protective equipment they need to work near this serious hazard.…

Floor Stickers – Your floors come alive and speak

Improve safety in your workplace by using these 10 types of floor signs.…

Washington State – Accident Prevention Program

Find out the basic requirements of an accident prevention program. Then learn how to implement or improve one.…

PPE: Personal Protective Equipment [Safety Standards]

Get an overview of common PPE requirements for the workplace including breathing protection, eye protection, and more.…

Valve Tags: Guide for Pipe Identification

Tips and recommendations for labeling the valves on your pipe system.…

The Definitive Guide to Globally Harmonized System (GHS) Labeling

Implementing GHS has been an evolving process for many companies. Here's what you need to know.…

Pipe Color Codes - ANSI/ASME A13.1

The ANSI/ASME A13.1 pipe marking color code explained.…

OSHA Facts

Everything you need to know about the Occupational Safety and Health Administration.…

Arc Flash [Facts, Safety Requirements & PPE]

Arc flash can cause serious damage to people and property. Learn how arc flash works and how you can prevent it.…

OSHA Floor Marking

Find out what OSHA has to say about marking your facility's floors.…

Process Safety Management

PSM is an OSHA standard developed for companies that handle hazardous chemicals.…

GHS Label Creation

Find out how to make Globally Harmonized System (GHS) labels in 3 steps.…

Floor marking comprehensive research, education and training

Everything you need to know about marking your facility’s floors. Types of markings, practical tips, and more.…

Workplace Safety Questions and Answers

What are the Metrics that can be Used to Measure Workplace Safety?

To evaluate the effectiveness of workplace safety within an organization, it is essential to analyze certain metrics which can help keep track of progress and identify potential areas which need to be improved. In this article, we discuss some examples of the metrics which should be tracked in order to accurately measure workplace safety, helping… …

What are the best Prevention Strategies for Human Error?

As we step into the era of artificial intelligence and automation, it’s easy to think less and less about the concept of human error. But, human errors still exist and permeate a lot of technological institutions today. These errors can range from harmless oversights to calamitous mistakes with potentially irreversible consequences. In this blog post,… …

Why are AEDs Necessary in the Workplace?

In today's fast-paced world, ensuring the safety and well-being of employees is a top priority for any responsible employer. The presence of an Automated External Defibrillator (AED) in the workplace is more than a safety precaution; it's a life-saving necessity. In this article, we'll delve into why AEDs are indispensable in the workplace, why every… …

How do I use an AED?

In moments of crisis, knowing how to use an Automated External Defibrillator (AED) can be the difference between life and death. This portable, life-saving device is designed to provide immediate assistance to individuals experiencing sudden cardiac arrest. In this article, we'll demystify the process of using an AED, from understanding what it is to the… …

What is an AED?

In today's fast-paced world, advancements in medical technology continue to play a pivotal role in saving lives. One such marvel is the Automated External Defibrillator (AED), a portable device designed to deliver a life-saving shock to a person experiencing sudden cardiac arrest. In this article, we'll delve into the history of AEDs, their modern design,… …

How Do I Create a Visual Workplace?

What do you think of when you hear “efficient communication, fewer misunderstandings, and enhanced productivity”? Well, no matter what your mind went to first, the relevant answer is Visual Safety. The Visual Workplace is a place where visuals revolutionize every corner of the workspace. As businesses lean towards digital transformation in a modern age, we… …

What are the safety concerns associated with working shifts?

There are many times when a facility can not get all the work completed throughout a single eight-hour shift. When this happens, it often becomes necessary to have employees on-site for two or even three shifts per day. While this certainly allows a single facility to get more work done each day, it does come… …

What are examples of a hazard?

Improving workplace safety means reducing or eliminating hazards in the area. In order to do that, however, you need to really understand what a hazard is. A hazard is generally defined as a source of risk, but that doesn’t always make it easy to identify them in your own facility. Looking at some examples of… …

Will exposure to hazards in the workplace cause injury illness or other adverse health effects?

When trying to evaluate the safety of a workplace, it can be tempting to look only at areas where people are injured or experience other problems. The fact is, however, that hazards often present themselves in ways that are not nearly as obvious. This is because most of the time when someone is exposed to… …

What is an adverse health effect?

By definition, an adverse health effect is the causation, promotion, facilitation, and/or exacerbation of a structural and/or functional abnormality, with the implication that the abnormality produced has the potential of lowering the quality of life, contributing to a disabling illness, or leading to premature death. When working on improving workplace safety, one of the most important… …

Why Should a Workplace Implement Hazard Controls?

One of the most important things that you can do for your workplace is to make it safer. Focusing on safety not only helps to minimize the risk for your employees, but it also helps to eliminate waste and improve the efficiency of your company. When you identify a potential hazard in your facility, you… …

Is Rotating Shiftwork Unhealthy?

In many industries it is necessary to have work being performed around the clock. When this is the case, employers have a variety of options to help ensure all the needed hours are covered. Sometimes an employer will simply set up multiple shifts of work and assign specific employees to specific times of work. While… …

What are corrosive chemicals?

Corrosive materials (sometimes referred to as caustics) are substances that will, through a chemical reaction, damage or destroy other substances on contact. In general, corrosives are either acids or bases: Acids: Hydrochloric acid, sulfuric acid, nitric acid, hydrofluoric acid, acetic acid, chromic acid, etc. Bases: Ammonium hydroxide, sodium hydroxide, potassium hydroxide, etc. Even though corrosives can be found… …

Why are emergency eye wash stations important?

The 10 to 15 seconds following a chemical splashing into the eye are critical to preventing extremely serious, and potentially permanent, eye injuries. Employees must have access to an emergency eye wash station to ensure they can quickly and properly flush away hazardous substances. Even if the proper safety precautions are being followed an accident can… …

What is meant by safety & health in the workplace?

When most people refer to health and safety efforts in the workplace, they primarily target eliminating workplace hazards to keep people safe from harm. However, the World Health Organization directly states that, “Health is a state of complete physical, mental, and social well-being and not merely the absence of disease or infirmity.” This infers that… …

Why do safety management systems fail?

To start off, there needs to be an explanation of what Safety Management Systems aim to accomplish for those who use them. A Safety Management System, or SMS, is more of a business approach to maintaining a safe environment. To put it simply, it works methodically to identify and monitor hazards and control risks continuously.… …

What is the scope of construction safety?

Construction safety is more than just handing workers PPE and demanding that they wear it at all times. In dangerous environments such as these, the employer must be in tune with all that goes on at the construction site. Regardless, the scope of construction safety also includes: Requiring Safety Training – Training is essential for… …

What is the purpose of using safety equipment?

To put it simply, the purpose of safety equipment is to keep people safe while working. However, its purpose extends even further than some may believe. There are a plethora of other benefits that a company can take advantage of if they obtain the right safety equipment for their facility. A handful of those benefits… …

How are accidents at the workplace prevented?

Preventing workplace accidents has a lot to do with knowing what kinds of hazards are around and doing the necessary work to mitigate or eliminate them. In fact, most workplace accidents that occur every year are entirely preventable with the right resources. With that being said, there are a number of actions an employer can… …

How do accidents occur at the workplace?

Accidents are more likely to occur in dangerous working environments. In fact, some of the most dangerous occupations that can be had in the U.S include the following: Logging workers Flight engineers and aircraft pilots Oil, gas, and mining occupations Roofers Garbage and recycling collectors Iron workers Delivery drivers Farmers Fire fighters Power linemen workers But… …

What is an occupational illness or injury?

Unfortunately, occupational illnesses and injuries happen frequently in a variety of working environments. In fact, around 2.8 million workplace related injuries and illnesses were reported by employers in 2019 alone, according to the U.S. Bureau of Labor Statistics. What exactly constitutes as a workplace injury or illness? Workplace injuries result from an accident that occurred on… …

What is workplace safety training?

Workplace safety training is meant to prevent incidents from occurring, enable employees to appropriately respond in the event of an emergency, and give everyone the necessary information they need to recover quickly after an incident. Safety training is the basis of overall workplace safety. If no one knows how to handle accidents or emergencies, then… …

What are the benefits of a Safety and Health Program?

Establishing and maintaining a Safety and Health Program benefits the company using it in countless ways. Overall, having one of these programs will assist with the following: Increases productivity and efficiency Prevents injuries and illnesses from occurring Helps decrease accidents, which saves the company money All law and regulation compliance efforts will improve Workers will… …

How can workplaces make safety a priority?

According to the U.S. Bureau of Labor Statistics, from 2018 to 2019, there has been a 2% increase in workplace fatalities coming out to a total of 5,333. That’s 3.5 fatalities for every 100,000 full time workers. The injuries recorded amounted to 2.8 cases for every 100 workers. This totals to 2.8 million workers that… …

How are hazards controlled in a confined space?

To the extent possible, people should avoid entering confined spaces because they can be extremely dangerous. Confined spaces can cause employees to become trapped, run out of air, get exposed to dangerous gasses, and much more. There are times, however, when it is necessary to have workers in these types of situations. When that is… …

Why is it important to prevent slips, trips, and falls?

Each year there are millions of accidents and injuries that occur in the workplace. While most of them are relatively minor, there are also some very serious and even fatal accidents that occur. Preventing accidents is an important task that can not only keep employees safer, but also improve the productivity of the facility. Very Common… …

What are hazards in a confined space?

A confined space are areas in the workplace large enough for a worker to enter but not designed for continuous occupancy and has limited or restricted means for entry and exits. Common on construction sites, some examples of confined spaces include pipelines, tunnels, manholes, ductwork. Some of the most common hazards of working in a confined… …

What are occupational health hazards?

Occupational hazards can make a cause a number of health problems for workers. These health hazards can fall under one of the six primary hazard categories: physical hazards, chemical hazards, biological hazards, ergonomic hazards, and behavioral hazards. Some common workplace hazards associated with health risks include: Loud noises: Hazardous noise levels or exposure to loud noises… …

What does FOD stand for?

FOD stands for foreign object debris and foreign object damage. The term is most commonly used in aviation or aerospace and refers to anything alien to an aircraft or system that could cause damage. However, FOD can also pose issues to a number of manufacturing sectors where foreign damage has the potential to compromise safety,… …

What is H2S?

Hydrogen sulfide, notated as H2S, is a toxic gas that can be recognized by its rotten egg smell. It can be found in places like sewers and swamps and has acquired the name sewer gas because of it. However, hydrogen sulfide can also be found in natural gas, volcanic gases, water sources, and even the… …

What does HACCP stand for?

HACCP stands for Hazard Analysis and Critical Control Point. This system is designed to fight safety hazards potentially present in food throughout the manufacturing process. Any company that is involved in manufacturing and processing food has the potential to implement the HACCP system and is highly encouraged to do so. It is used to protect… …

What does LEL mean?

LEL (lower explosive limit) and LFL (lower flammable limit) are used interchangeably according to fire science literature and regulation. The LEL is the defined minimum concentration of gases and vapors suspended in the air that allows for ignition in the presence of an energy source. On the opposite spectrum there is the UEL (upper flammable… …

What does CDC stand for?

The Centers for Disease Control and Prevention known as the CDC, is one of the largest components of the Department of Health and Human Services. The federal agency’s story began during the summer of 1946 when malaria was rampant in the South. Their sole mission back then was to prevent the disease from spreading any… …

What does AED stand for?

An automated external defibrillator, also known as an AED, is used in emergency situations where someone is experiencing sudden cardiac arrest. AEDs are small easy to use devices that deliver an electrical shock, known as defibrillation, to the affected person. That shock assists in re-establishing the heart’s proper rhythm. The two abnormal heart rhythms that… …

What are examples of administrative controls?

Administrative controls are changes in the way that things are done in an attempt to improve safety. There are many ways that they can be used to help reduce workplace hazards. In most cases, administrative controls are implemented voluntarily to help ensure that a facility and its employees are as safe as possible. In other… …

What is a risk assessment?

A risk assessment is an effort that is made to identify what risks may be present in a given area, with the goal of finding ways to reduce or eliminate those hazards. In addition, when assessing a risk it is necessary to try to identify what will happen should that risk take place. There are… …

What is the goal of a risk assessment?

There are quite a few potential goals of a risk assessment. At the core, the main goal is always going to be to improve workplace safety and make sure that a company is prepared for any type of hazard that may occur. The specific goals will vary greatly depending on the type of risk that… …

What are hazard controls?

Hazard controls are various types of steps that can be taken to limit or even eliminate various hazards in the workplace. These steps are organized into a hierarchy of controls, so people can attempt to perform the most effective option first, and then go down the list until they reach the bottom. In some cases… …

What are safeguards?

Improving safety in the workplace takes more than just telling people to wear personal protection equipment or finding ways to eliminate hazards. Your workplace safety strategy needs to look at every possible way to keep people and the facility safer and implement the most effective options. Safeguards are steps that can be taken to make… …

What does emergency egress mean?

Egress is a term that is quite similar to exit, but it has additional meaning associated with it when it comes to discussing workplace safety and related topics. Egresses in a building need to be planned in such a way as to ensure everyone in a building is able to get out quickly in the… …

What is a cleanroom?

Cleanrooms are controlled environments that aim to have as low a level of pollutants as possible. They have parameters in place that control the amount of contamination from chemical vapors, aerosol particles, airborne microbes, and dust, and are used in any industry where small particles have an adverse impact on the manufacturing process. While they… …

What does JSA stand for?

JSA stands for Job Safety Analysis. It is a procedure that is designed to help bring together various proven safety and health principles into practice in a real-life situation. This is done by looking at each step of a job to pinpoint various potential hazards that may be present. Once these hazards are identified, a… …

What does CBRN stand for?

CBRN stands for Chemical, Biological, Radiological, and Nuclear. It is often used in the context of ‘CBRN defense,’ meaning what types protective measures can be taken to keep one safe from exposure to these types of hazards. This term can be used in workplaces where dangerous chemicals or other substances are used, for emergency responders.… …

What does CCP stand for?

CCP stands for Critical Control Point, a point at which preventative measures must be applied in order to reduce, prevent, or eliminate a safety hazard. Most widely used in the food industry, CCPs are essential steps within a business’s entire process, from purchasing raw ingredients to the way the food is plated and served for… …

What is a hazard?

The most common definition of hazard is ‘a danger or risk’ that is associated with something. The hazard has to be able to cause some type of harm or potential harm to either a person or something else in the area. Something can even be considered a hazard if it would be a trigger for… …

What is a confined space?

Workplace safety is going to look very different depending on what environment people are working in. One of the most dangerous places that people work are confined spaces. Confined spaces are areas where there isn’t very much room for the person to perform their work. The OSHA definition of confined spaces says that the area… …

What is EHS?

EHS is an acronym for Environment, Health, and Safety, and it is a system that many companies implement to promote the safety of their workers, the general public, and the local environment. It involves a variety of regulations and processes that ultimately ensure there are no negative consequences resulting from a company’s day-to-day operations: no… …

What does RFI stand for?

RFI stands for a “request for information.” These requests are an official form of communication that OSHA occasionally issues with the aim to receive feedback on the agency’s established standards. OSHA utilizes the expertise of professionals in the actual field or industry of the standard in question. A deadline is provided for employers to give… …

What does BBS stand for?

When it comes to workplace safety strategies, BBS stands for Behavior-Based Safety. It is a system that looks at the science of behavior in order to make improvements on real world safety concerns. Rather than focusing specifically on what looks like it will work on paper for safety improvement, BBS looks at what real people… …

What is dB?

dB, written with a lowercase d and a capital B, stands for decibel. While most commonly used to measure how loud a sound is, dB is more properly a measurement that is used to express the value of a power or field quantity to another. It can be used in many different fields including perception,… …

Is there a way to fall safely?

Falls are responsible for a large percentage of workplace injuries. Whether it is tripping over an object, slipping and falling on a wet floor, or falling from a ladder, they can all be very dangerous. While it is obviously best to avoid falls entirely, there are some things you can do to help minimize your… …

What does a safety professional do?

Safety professionals are individuals who typically work in the manufacturing, warehousing, or industrial settings. Their job is to analyze the workplace environment for potential risks, and based on that information, come up with ways to improve the safety in the facility. Those who wish to work in this role will typically need at least an… …

What is the difference between a job safety analysis (JSA) and a risk assessment?

Judging just on the names and the broad reason for performing them, a job safety analysis (JSA) and a risk assessment sound like they would be very similar activities. While it is true that they have some things in common, they are unique tasks that should be performed by any workplace environment. When used together,… …

What is CRM in safety?

Crew resource management, or CRM, was first developed in the 1950’s for the Royal Air Force. The original concept was specifically for pilots and other flight crew, and was even called cockpit resource management. Over time, however, it was found that the same concepts can be used in any environment where human error can lead… …

What is process safety management (PSM)?

Process safety management is an analytical tool that is used to prevent any type of release of substances that are considered to be ‘highly hazardous chemicals’ by either the EPA or OSHA. This process is designed to help reduce the frequency (and severity) of chemical spills. Any facility that creates, ships, or uses any type… …

How are accident reports written?

When an accident occurs in the workplace it is important to do everything possible to get the treatment you need right away. Even if you don’t believe the injury is to serious or life threatening, it is typically best to go to the doctor to get it checked out. Once you are certain that you… …

What are the steps to becoming a safety manager?

Working as a safety manager is a great job if you can find the right company to work for. In some cases, you can transition into this type of position by performing well in other roles, then getting trained by the existing safety professionals. For most people, however, it will be necessary to go through… …

What is a crane?

A crane is a specific type of machinery that is used to lift and lower various materials. It is most commonly used in construction projects but can also be used to move large items like pianos into a position that would otherwise be impossible. Cranes can be extremely large and tall, or much smaller and… …

What are ways to stay awake at work?

In a perfect world, everyone would get a full eight hours of sleep at night and feel awake and ready to go throughout their day at work. In reality, however, just about everyone has experienced the feeling of exhaustion in the workplace. This is not only bad for productivity, but it can also be extremely… …

What is FOD?

In many workplaces it is not uncommon for people to talk about “FOD.” While the acronym FOD has many meanings in various different settings, it most commonly means ‘Foreign Object Damage’ when you hear it in a manufacturing setting. Foreign object damage is any type of damage that is caused when a foreign object enters… …

What is a JHA?

JHA stands for Job Hazard Analysis. This is an important part of any risk assessment where an employer attempts to discover potential hazards that exist in the workplace. This can be done to find hazards that are specific to one task, to one job type, or even to an entire facility. When done properly, the… …

What is composite risk management (CRM)?

Composite risk management (CRM) is a proven process that is used for decision making. It was originally developed by the US military to help acknowledge, access, and address various hazards. It is also used to control risks during missions as well as normal day-to-day activities. The CRM process is broken up into five steps that… …

What's inside a first aid kit?

First aid kits are mandatory in every workplace from offices and warehouses to outdoor occupations. You never know when an accident will strike, which is why these nifty kits exist. The absolute minimum requirement for first aid kits kept in the workplace are classified into two different sizes according to the American National Standards Institute (ANSI)… …

How is workplace safety regulated and enforced?

The safety and health conditions in the majority of businesses in the private sector are regulated by OSHA and the OSH Act of 1970. The act is then primarily enforced by compliance safety and health officers. These officers are trained industrial hygienist professionals who conduct OSHA inspections in businesses all across the country. OSHA inspections are… …

Who regulates workplace safety?

Occupational safety has only been researched and regulated for a relatively short amount of time with the first session of the International Labour Organization/World Health Organization Committee on Occupational Health in 1950. Since then, government agencies, institutions, and organizations have worked to develop and enforce regulations that promote and maintain physical, mental, and social well-being. In… …

When and how often should I conduct workplace safety training?

One of the most effective ways to keep workers safe while on the job is to provide training. OSHA believes training is essential to any safety and health program and as an employer, you will need to meet their standards for training and education. While training is often different from facility to facility, there are general… …

What is the hierarchy of hazards?

The hierarchy of hazards, also referred to as the hierarchy of hazard controls is an approach used to effectively address safety risks in the facility. After performing a job safety analysis, you will have a list of different kinds of hazards: chemical hazards, physical hazards, health hazards, and more. There are five levels to the… …

How can I improve my workplace safety?

Workplace safety should be a continuous effort for any company. You will most likely never achieve perfect safety, so there will always be areas for improvement. Here are some ways you can start improving the safety or your facility: Organize: Often times a messy or cluttered facility can lead to injury. A great first step… …

What is the role of PPE in workplace safety?

Personal protective equipment, or PPE, is any type of equipment or clothing worn by a person to protect them from a specific hazard and minimize exposure to the hazard. Industrial workplaces can often be a dangerous place, and PPE is an effective and proven way to improve the safety of a facility. Every day workers are… …

How does visual communication impact workplace safety?

Visual communication, also referred to as visual management, is a tried and true method for improving and sustaining workplace safety. It encompasses a variety of different supplies: wall signs, equipment labels, chemical labels, floor signs, industrial floor tapes, and more. Not only are there are a number of visual communication supplies on the market, your… …

How does workplace safety effect efficiency?

There is a common saying amongst safety professionals: a safe workplace is an efficient workplace! Production is positively and indirectly impacted by an effective safety and health program. Improved morale and productivity Studies have shown that when a safety culture is developed in a facility, employee productivity significantly increased, and factory costs noticeably decreased. The study… …

What are workplace safety requirements?

There are hundreds of standards and regulations that have been developed to improve safety in the workplace. All over the world there are different governmental agencies, institutions, and organizations who work to develop these standards and regulations. In the United States, the Occupational Safety and Health Administration is the agency who sets workplace safety requirements… …

Why is workplace safety so important?

Keeping workers safe is arguably the employer’s most important job and OSHA law requires “employers to provide their employees with working conditions that are free of known dangers.” If you are running an unsafe operation, consequences can be serious, even deadly. Not only is it the law to keep your workers safe, but it is your… …

What is a job safety analysis?

One of the best ways to identify and remedy safety risks in the workplace is through performing a job safety analysis. A job safety analysis, sometimes called a job hazard analysis or a job hazard breakdown, is a pretty self-explanatory term. It is a review of a job in the facility to help identify safety… …

How can floor markings improve safety?

Visual communication is an excellent tool for promoting and maintaining a safe workplace. When people think of visual communication, they often think of safety posters, warning signs, and caution tape. While these are all correct answers, it is important to not overlook floor markings! Whether in a manufacturing plant or in a warehousing facility, you… …

What are common hazards at a construction site?

Sidewalks, repairing roads, and maintaining the infrastructures of cities. Construction workers are a part of the day-to-day life in cities but are often working in hazardous conditions. Below are some of the most common dangers found in a construction site. Confined spaces: Construction workers often find themselves working in confined spaces. Those working in spaces… …

What are common safety hazards in a facility?

There are some occupational hazards that are present no matter where you ago. Across the word and across industries, workers every day are faced with hazards in their workplace. This list is just a few of the most common safety risks found in a facility: Forklifts: Manufacturing and warehousing facilities usually have powered industrial trucks,… …

How can workplace safety be maintained?

Under OSHA law, it is required that employers create and maintain a safe work environment. Assessing the workplace and implementing safety measures are an excellent first step, but efforts must be maintained to keep workers safe and healthy. One of the best ways to maintain a safe facility and promote a safe culture is through visual… …

What are different types of workplace safety?

OSHA has identified five different types of hazards that most workplaces. These are hazards that can be found in nearly every type of facility and should be addressed to keep workers from injury or health problems. Safety hazards: Safety hazards are the most common type of hazard and they are present in virtually every workplace… …

How can I include Spanish in my safety program and resources?

Language barriers in the workplace can have a direct impact on the effectiveness of safety programs. The first step to an effective safety program that accommodates Spanish-speaking workers is to add bilingual employees to the safety committee. By having Spanish-speaking individuals on the committee, you can ensure Hispanic employees are comfortable with talking to the… …

![Electric Arc [Definition, Applications & Arc Flash]](https://www.creativesafetysupply.com/content/images/articles/electrical-arc-th.jpg)

![OSHA Sign Compliance: ANSI 1967 vs. ANSI 2011 [With 2017 Updates]](https://www.creativesafetysupply.com/content/images/articles/ansi-sign-headers-th.jpg)

![HAZWOPER [OSHA Hazardous Waste Standard]](https://www.creativesafetysupply.com/content/images/articles/hazwoper-thumb.jpg)

![OSHA Card [Program Requirements + Benefits]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-osha-10-card.jpg)

![Hard Hat Classes [OSHA & ANSI Standards]](https://www.creativesafetysupply.com/template/images/articles/hardhat-classes-thumb.jpg)

![ANSI/ISEA Z87.1 Standard [Eye Protection + Safety Glasses]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ansi-safety-glasses.jpg)

![PPE: Personal Protective Equipment [Safety Standards]](https://www.creativesafetysupply.com/template/images/custom/resources-page/articles-ppe.jpg)

![Arc Flash [Facts, Safety Requirements & PPE]](https://www.creativesafetysupply.com/template/images/custom/safety-articles/articles-arc-flash-facts.jpg)