Published by the National Fire Protection Association, NFPA 704 is a labeling system used to quickly identify any health, flammability, reactivity, or special risks associated with hazardous materials. The NFPA 704 standard guides the user through establishing a supplemental labeling system to protect both emergency personnel and employees within normal working conditions.

Emergency responders such as paramedics, police officers, firemen, and others are typically trained to read these labels and understand them quickly. For example, with these special labels, an emergency responder would be able to recognize the need for respiratory protection quickly before entering an area where chemicals have been spilled.

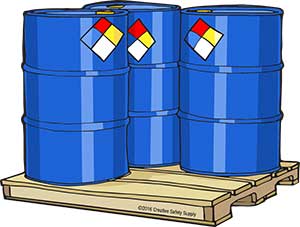

That said, with its diamond shape, vibrant colors, and clearly visible numbers and symbols, an NFPA 704 label is easily identifiable. NFPA diamond labels can be used on any type of chemical container to alert people of existing hazards.

What are Hazardous Materials?

A hazardous material is defined as an item or agent that can cause harm to people, wildlife, and the surrounding environment. Naturally, employers will want to eliminate these hazards entirely from their facilities. If elimination is not attainable, then employers may want to hire an EHS professional or work to mitigate the risk of worker exposure by themselves.

Hazardous materials have the capacity to severely injure employees; exposure may even result in occupational fatalities. It is for that reason why NFPA 704 labels exist.

What is Counted as a Severe Hazard?

Exposure to a severe chemical hazard, no matter if it is classified as flammable, reactive, or detrimental to the health of the worker, has the potential to result in a situation that is either life threatening or fatal.

Take for example the IDLH standard, which was created by the National Institute for Occupational Safety and Health (NIOSH). Severe atmospheric hazards are characterized by exposure concentrations, which dictate how employers choose respirator PPE.

There are all different kinds of severe hazards out there. Because of that, there are many different regulations like NFPA 704 that establish best practice methods for keeping workers informed and safe in the environment that surrounds them.

Recognizing NFPA 704 Diamonds

The NFPA 704 label contains an incredible amount of information in a compact and easy-to-understand format. This is essential for all emergency situations to be able to respond quickly. The label is made up of four smaller color-coded diamonds that make up one large diamond shape.

Each color-coded section of blue, red, yellow, and white represents a different type of hazard. With the exception of the bottom white diamond, there will be a number that corresponds to the level of danger a chemical poses.

On a scale of 0-4, zero represents no hazard at all and four represents an extreme hazard. The hazard diamond prepares workers for potential exposure. Each number also has a specific meaning based on which diamond it is in.

Left Diamond | Health Hazard | Blue

The blue diamond on the left side of the NFPA label is used to alert people of existing health hazards.

The higher the number, the more precautions someone must take when working with the chemical or dealing with an emergency. The numerical codes used in this section are broken down as follows:

- 0 – Chemicals in this level pose no health hazard and do not require any protection methods. Chemicals like water and others that are entirely safe under normal use can be labeled with a zero in this category.

- 1 – Level one for the health hazard category is for any chemical that will only cause mild irritation or injury due to exposure. In most situations, no extra personal protective equipment is needed beyond perhaps gloves.

- 2 – Level two is designated for chemicals that have the potential to cause temporary incapacitation or residual injury, but only if there is intense or prolonged exposure to the chemical.

- 3 – This level is reserved for chemicals that will cause either a temporary or moderate residual injury within a short exposure period.

- 4 – Level four chemicals can cause serious injury or death with even brief or limited exposure. Extreme precaution is necessary at this level. Personal protective equipment needs to be worn before working with this chemical or even the container that holds it. This is especially true during an emergency such as a chemical spill.

Common Workplace Health Hazards

According to OSHA, there are many different health hazards that pose a risk to workers and the public. These include physical hazards, chemical hazards, ergonomic hazards, and biological hazards. All of which cause harm directly to the human body.

However, in the world of NFPA 704 labeling, storage containers are geneerally labeled with the health hazard numbering system when confronted with dangerous chemical.

Health hazards can include skin irritation, diseases such as cancer, respiratory issues, or any number of other health related risks. If used in conjunction with GHS labels, the user may notice four different categories of pictograms that denote a health hazard:

- Corrosive

- Toxic

- Harmful

- Irritation

Top Diamond | Flammability | Red

The red diamond on the top of the NFPA label is known as the fire diamond. Chemicals that cannot burn will have a zero in this diamond, and those that are extremely flammable will have a four. Most chemicals will have a rating somewhere in between. The number breakdown for this section is as follows:

- 0 – Any label that has a zero in this diamond is a material that will not burn, even in typical fire conditions. The specific standards followed for this level state that this is for materials that will not burn while in the air and exposed to a temperature of 1500°F for five minutes.

- 1 – Any material or chemical that will burn, but only when heated significantly. These materials must have a flash point of 200°F or higher.

- 2 – Any material or chemical that needs to be exposed to a "relatively" high temperature before it will ignite is placed under this designated rating. Flash points between 100°F and 200°F are in this level.

- 3 – In category three belongs the chemicals that will ignite under most ambient temperatures, has a flash point below 73°F, and has a boiling point of only 100°F.

- 4 – Items found in this category will readily burn and have a flash point that is below normal room temperatures (73 degrees). These are the most dangerous and include chemicals like acetylene and propane.

Common Fire Hazards in the Workplace

Many workplaces have existing fire hazards that they must store and label correctly to prevent fires from occurring. These hazards are especially prevalent in manufacturing and construction industries, as well as in agriculture.

There are three primary forms that flammable and combustible hazards exist in:

- Liquids such as diesel, gasoline, paint thinners, solvents, etc.

- Gases such as propane, methane, and hydrogen, etc.

- Solids such as metal dusts, carbon-based dusts, and even some foods.

Flammable solids, liquids, and gases pose a high risk to both employees and the facility since combustion in both confined spaces and outdoor areas can result fatalities as well as property damage. For that reason, it is critical that these hazards are labeled appropriately.

Right Diamond | Instability | Yellow

The yellow diamond on the right side of the NFPA label informs people about how stable the chemical is.

It must be noted that this section of the NFPA diamond label will not provide any information about what causes the chemical to be unstable. Emergency response teams must look further into the nature of the chemical to learn this, and if chemicals are unable, responders should take extreme precaution to avoid any type of reaction.

The levels for this section are:

- 0 – A zero signifies a very stable substance. It will not react even under conditions such as fire or immersion in water.

- 1 – A one signifies stability under most conditions, but when temperatures or pressures are elevated significantly, the substance may become unstable.

- 2 – Chemicals labeled as a two in the yellow diamond can undergo a violent chemical change when exposed to elevated pressures or temperatures. In addition, they may have serious reactions when exposed to water.

- 3 – A three signifies high instability properties. This chemical may explode or detonate after an ignition or when exposed to heat. This type of chemical may also have a serious reaction to water or a shock.

- 4 – Chemicals at this level can react or detonate even at normal pressures and temperatures. They need to always be kept in a well-regulated environment to ensure a dangerous reaction doesn’t occur.

Common Instability Hazards in the Workplace

Stability refers to how easily a chemical can change or undergo some type of reaction; you may think of it as detonation or an explosion. Highly unstable chemicals can react with something as simple as being exposed to air, water, or being shaken.

Some examples of substances with a high reactivity rating include:

- Ethyl Nitrite

- Fluorine

- Hydrogen Peroxide

Reactivity information is essential, just like the other hazard rankings. Labeling these hazards gives the workforce and emergency personnel the information they need to stay safe around these substances.

Bottom Diamond | Special Precautions | White

The white diamond at the bottom of an NFPA label does not contain a number like the others because it does not list the severity of a particular type of hazard. Instead, this diamond contains symbols that convey special precautions or hazards that employee may be exposed to.

There are three symbols approved by the NFPA 704 system:

- W – A “W” indicates a strong reaction to water. Chemicals like potassium, magnesium, rubidium, and cesium that will explode, burn, or give off dangerous gases when exposed to water. This is an especially important warning for firemen and other emergency responders not to use water on or around this chemical.

- OX – The “OX” symbol indicates a violent reaction if exposed to oxygen. A strong oxidizer like ammonium nitrate, or perhaps ketone peroxides, bromates, and chromates, should be labeled with this symbol to avoid puncturing or opening a container.

- SA – Used for simple asphyxiate gases, the “SA” marking warns workers of gases that reduce or displace oxygen in the area. Gases, or chemicals in liquid form that can evaporate, can cause this reaction. Nitrogen, helium, neon, and argon are the primary culprits.

There are also several "non-standard" symbols commonly used by facilities. While not officially a part of the NFPA 704 system, it is a good idea to be aware of their existence because of their widespread use. These symbols are:

- COR, ACID, ALK – These symbols are used for any chemical that is corrosive, including strong acids and bases.

- BIO – Any chemical that presents a biological hazard may be labeled with this symbol.

- POI – All poisonous chemicals fall under this symbol.

- RA or RAD – Any radioactive chemicals can be labeled with this symbol.

- CRY or CRYO – Cryogenic chemicals may have this symbol listed in the white diamond.

Where NFPA Diamond Labels Are Used

Unlike many other labeling systems, the NFPA 704 labeling system is not required. The National Fire Protection Association is not a government agency like OSHA, and because of that, it has no power for enforcement. Businesses and individuals use this system because it is effective and can dramatically improve safety in many instances.

People will notice this type of label in a wide range of areas. Some of the most common places the average person will see an NFPA 704 label are outside buildings, on doors, and holding tanks. Should any of these objects or places be involved in an accident, the NFPA fire diamond lets emergency responders know what they're dealing with.

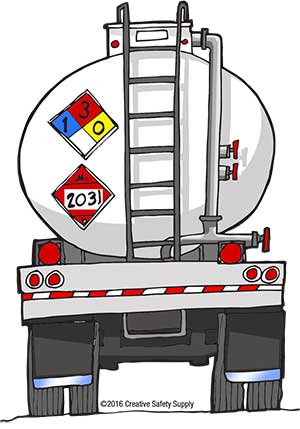

NFPA fire diamonds are often confused with DOT placards used on transportation vehicles. In most cases, a DOT placard will be physically attached to the truck and made of metal. The truck driver can move the label around to change the numbers in the diamonds, which makes it a flexible option that can be used for any type of chemical.

Additional NFPA 704 facts:

- NFPA 704, also known as a fire diamond, is a diamond-shaped sign or picture that tells people about the hazards of a chemical compound. It was designed in 1960 by the National Fire Protection Association, as a way of quickly telling firefighters and other emergency workers what kind of dangers might be nearby. Source: https://en.wikipedia.org/wiki/NFPA_704

- NFPA 704 represents a diamond with colored safety square and embedded number from 0 to 4. Zero signifies no hazard and 4 presents maximum risk. The four divisions are typically color-coded with red on top indicating flammability, blue on the left indicating level of health hazard, yellow on the right for chemical reactivity, and white containing codes for special hazards. Source: https://batteryuniversity.com/article/bu-704d-nfpa-704-rating

- NFPA 704 is a standard maintained by the U.S.-based National Fire Protection Association. It is an internationally accepted safety standard, and is crucial while transporting chemicals. Source: https://en.wikipedia.org/wiki/NFPA_704

- The development of NFPA 704 is credited to the Charlotte Fire Department after a fire at the Charlotte Chemical Company in 1959 led to severe injuries to many of the firefighters. Upon arrival, the fire crew found a fire burning inside a vat that firefighters assumed to be burning kerosene. Source: https://en.wikipedia.org/wiki/NFPA_704

- NFPA 704 is not a regulation, but rather a voluntary consensus standard that can be adopted by local authorities. It is not intended for use by the general public, and should not be confused with the hazard symbols used in consumer product labeling. Source: https://www.nfpa.org/codes-and-standards/7/0/4/nfpa-704

Similar Articles

- NFPA 704

- Hazardous Materials Identification System (HMIS Labels)

- GHS: The Globally Harmonized System for Labeling [Updated 2019]

- NFPA 99: Understanding the Health Care Facilities Code

- Solar System Labeling

- Waste Water Treatment Labeling

- Arc Flash Labeling (Updated)

- ANSI Color Codes for Pipe Marking

- Pipeline Labeling