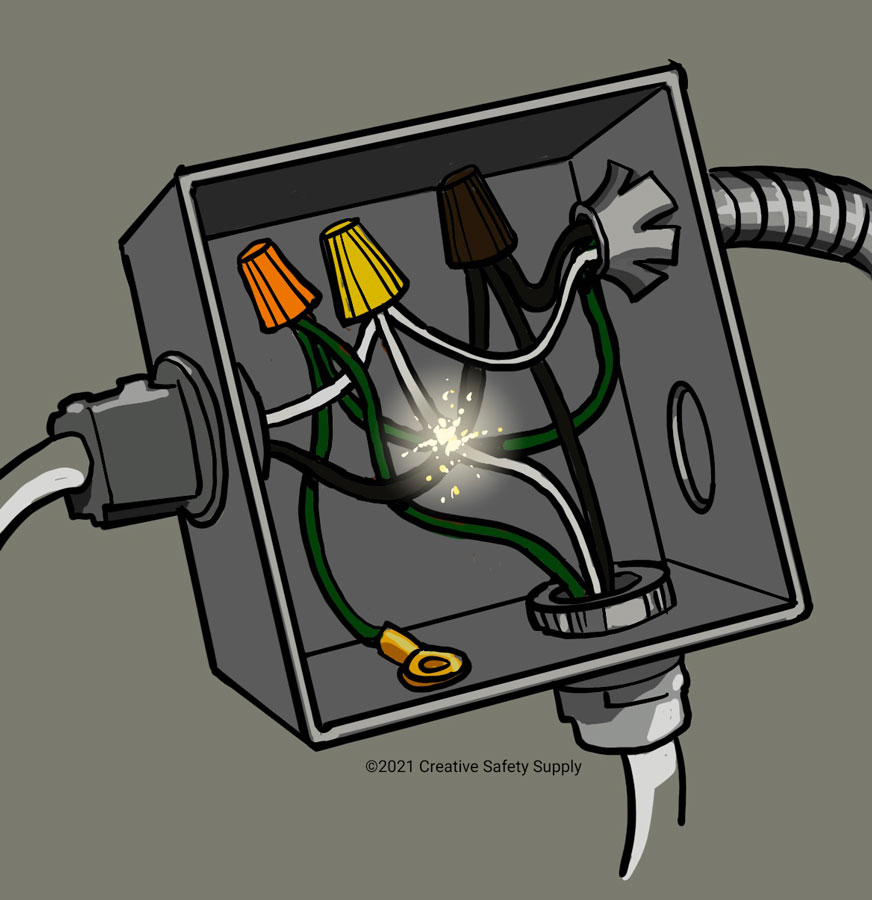

Electrical arcing occurs when a discharge of electricity is produced during an electrical breakdown of gases within the air. This discharge is continuous rather than momentary, which is what separates an electrical arc from an electric spark. The current’s intended path becomes disrupted, and it will instead travel between two points, either from one conductor to another, or a grounded object nearby. When this happens, the conduction of electrical current is uncontrolled and the surrounding air is ionized. The point of the arc produces extreme light and heat, and this is known as the arc flash. An arc flash can cause severe injuries to workers nearby as well as property damage.

Electrical arcing may take place due to:

- Accidental contact with equipment that is energized

- Breaks or gaps in insulation

- Exposed and frayed wires

- Equipment failure

- Regular wear and tear on the conductor’s surface

- Plug outlets that become overloaded

- Impurities such as corrosion and dust

- Electrical equipment and systems that are poorly maintained

Electrical arcing can be extremely dangerous. It results in the release of an enormous amount of energy that may cause fires, severe burns, damage to eyesight and hearing, release poisonous gas, and even create a shockwave/blast that is similar to an explosion.

What Can Be Done to Prevent Electrical Arcing?

Preventative measures may be taken to restrict electrical arcing. The first step is to ensure that over-current protection devices are properly installed. Since 2002, the National Electrical Code (NEC) requires new construction to incorporate arc fault circuit interrupters (AFICs) within electrical panels. Once a stray current is detected, these devices automatically shut down the circuit. Another preventative measure is to de-energize equipment before operation. Statistically, most injuries related to electrical arcing occur while equipment is in use. Through de-energizing, the chances of stray electric currents traveling between conductors or jumping to workers are minimized or eliminated. It is required by the NEC to conduct an Electrical Hazard Analysis before working near or on electrical conductors, such as equipment. This determines whether the conductors could be energized, what actions should be taken while work is being completed, and what else could be done to protect electricians and other workers who are regularly in contact with conductors that are potentially energized.

Additional Electrical Arcing facts:

- Electrical arcing is a type of electrical discharge that occurs when electrons flow between two conductors, usually metal, in an environment with a gas or vacuum. The conductors can be wires, rods, or other objects that are capable of carrying an electrical current. Source: https://www.hunker.com/13418905/what-are-the-causes-of-arcing-in-an-electrical-panel/

- Electrical arcing can produce intense heat, light, sound, and electromagnetic radiation. The temperature of an arc can reach up to 35,000 degrees Fahrenheit, which is hotter than the surface of the sun. Arcing can also generate harmful gases, such as ozone and nitrogen oxides, and pose a risk of electric shock, burns, and fire. Source: https://www.acelectricohio.com/what-is-electrical-arcing/

- Electrical arcing can be caused by several factors, such as overload, damage, corrosion, loose connections, moisture, dust, or foreign objects in the electrical system. Arcing can also occur naturally, such as in lightning, or intentionally, such as in welding, plasma cutting, or neon signs. Source: https://www.worldwidefaqs.com/what-causes-electrical-arcing/

- Electrical arcing can be prevented or minimized by using proper insulation, grounding, fuses, circuit breakers, arc fault circuit interrupters (AFCIs), and personal protective equipment (PPE). Regular inspection, maintenance, and repair of electrical equipment and wiring can also help avoid arcing hazards. Source: https://www.worldwidefaqs.com/what-causes-electrical-arcing/

- Electrical arcing is a subject of scientific and engineering research, as it has many applications and challenges in various fields, such as power transmission, aerospace, medicine, nanotechnology, and fusion energy. Source: https://www.acelectricohio.com/what-is-electrical-arcing/

Similar Questions

- What is an arc flash?

- Where do arc flashes occur?

- How does an arc flash occur?

- What is the difference between an arc flash and an arc blast?

- What is an electrical arc?

- How do I prevent an arc flash from happening?

- At what voltage can an arc flash occur?

- Who is at risk of an arc flash?

- How do I complete an arc flash hazard analysis?