Scanning a high volume of barcodes easily is a high priority in many industries, whether it be because of an increase in demand or the sheer number of items and tasks that need to be completed within a time limit to facilitate smooth process flow. When referring to barcodes, the one type that instantly comes to mind are the standard one-dimension codes that can normally be seen everywhere, whether that be on food, products, components, or even on rack labels for storage purposes in large warehouses. These simple one-dimensional barcodes often have issues with becoming damaged and unreadable, can only hold a very limited number of characters, and must be scanned from precisely the correct direction.

As can be imagined, this all adds up to a slow-going process for everyday work revolving around inventory management and information tracking within warehouses and other industrial facilities. However, incorporating a different type of two-dimensional barcode called the QR code can make the scanning process much easier and faster to those who rely on barcodes for gathering information.

QR codes began to appear in the year 1994. Created by the company Denso Wave in Japan, these special barcodes were meant to track vehicles during the manufacturing process via a quick component scan. Since then, the possibilities have expanded in regard to what QR codes can be used for thanks to Denso Wave who allowed for the creation of these codes to be freely available to the public. This way, everyone had even more options to improve their current information gathering solutions.

What are QR codes?

QR codes are made up of black square dots and white spaces arranged in a square grid. This layout enables the code to store data by using patterns and is then able to be translated once scanned by a specifically made scanning device, or smart phone. Apps that are able to scan QR codes are becoming more and more popular as companies use these codes for advertising and other marketing schemes. Overall, QR codes provide an easy access to information, and not to those who are just looking to manage inventory.

Need QR codes?

Our free QR code generator allows you to create custom QR codes readable with any scanner.

Since QR codes are two-dimensional, these nifty little square barcodes are able to hold an astounding amount of information, up to 7,089 digits or 4,296 characters to be exact. Compare that number to the standard one-dimensional rectangular barcodes that hold less than 100 characters. Those, known as UPC, are simple barcodes that can be seen at retail stores as “price codes” and at manufacturing or distribution facilities as an alternative to manual inventory management.

QR codes can be seen everywhere due to the barcode’s enormous capacity for holding information as well as its ability to be scanned in any orientation quickly. Some of the most common places they can be found residing on include:

- On business cards, paper handouts, at restaurants, and in retail establishments.

- All types of advertising material. They can be on billboards, TV commercials, on product packaging, etc.

- On inventory tags containing information like serial numbers, part numbers, hardware specs, inventory dates, and so on.

The information contained on these types of barcodes can be any of the following examples:

- Simple text

- Addresses

- Phone numbers

- E-mail addresses

- URLs

- Payments

- Online account authentication

- Wi-Fi authentication

What Does QR Code Stand for?

Also known as Quick Response codes, these barcodes do just that. Their square shape and specific design components allow for the scanner to translate information ten times faster than other barcode types, and do so at any angle it’s scanned from.

The ability to scan from any angle, at a longer distance, and with a higher rate of accuracy, means that those using this code will have the information they need to get their task done efficiently and effectively. This is especially relevant when speaking about inventory management and asset tracking as those are integral parts of a working production line, which means accuracy and speed matter in terms of costs relating to production, labor, obtaining enough components to meet demand, and yet not buying too much.

How Does a QR Code Work?

There are two classifications of QR codes that can be chosen depending on whether or not the user is wanting a code that can be changed as new information is acquired. They are called static QR codes and dynamic QR codes.

Static QR codes are ones that cannot be updated once the code has been generated. The information is permanently fixed which makes the use of static QR codes useless for marketing tactics, tracking, or inventory management. Instead, these codes are preferable for instances where unchanging information is necessary, such as the sending of a simple text, or providing a Wi-Fi login to guests for them to automatically connect to.

On the other hand, dynamic codes are more useful for information and data that changes constantly. This would normally come with a larger code printed on the material since there would be a lot of information, but dynamic codes have the ability to redirect the user to a URL address. This in turn can keep the code small on packaging, which is useful in terms of cost savings and integrating the code onto products for many facilities.

The next aspect of how these types of 2D barcodes work is the fact that there are forty versions of them that can be chosen from. The smallest code, version one, has 21 modules. Modules are the smallest element on a QR code, which are the individual black and white squares that make up the code. Every version after version one increases by four modules per side, making version forty have 177 modules on each side. Now, as the version size increases, so does the amount of information it can hold.

There are four different encoding modes that a QR code has access to in terms of storing information. Those are:

- Numeric

- Alphanumeric

- Byte/binary

- Kanji

The maximum data capacity is entirely dependent on the version of the QR code, the type of encoding mode used, and the error correction level specified. There are four of these error correction capacities, each referred to as the following:

- L (Low) – Error correction level of 7%

- M (Medium) – Error correction level of 15%

- Q (Quartile) – Error correction level of 25%

- H (High) – Error correction level of 30%

Error correction levels enable the label’s stored data to be read correctly in the event the code has been covered in dirt, scratches, or any other level of damage that would render a simple barcode useless. This useful superpower that QR codes have enables the users to not only read partially damaged codes accurately, but it also allows for the creators to make unique QR codes in the realm of having special designs or logos on the QR code itself. This presents a recognizable symbol to those who scan the QR code in which they can remember the company by. It can essentially morph into a marketing tool.

Design Basics of a QR Code

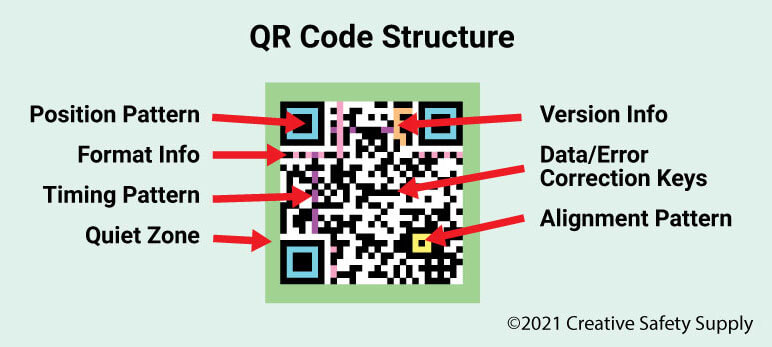

Now that we’ve explained how QR codes work, the details of each part that makes up a QR code must be deciphered. The following seven patterns appear within every QR code and each serve a specific purpose:

- Positioning detection markers – These are the three boxes in the top right and left, and the bottom left corner. These boxes are the key to a fast-scanning speed as they are able to have the scanner orientate the QR code no matter what direction it is scanned in.

- Alignment markings – Usually in the bottom right corner is what’s called an alignment marking. This box is smaller than the three positioning detection markers, but it helps scanners read the code when it’s placed on a curved surface. It is also good to remember that the bigger the code, the more of these patterns are needed.

- Timing pattern – Think of this pattern as a dotted line. When scanned, the dotted line is able to tell how large the data matrix is within the QR code.

- Version information – There are forty different QR code versions that exist, and naturally scanners need to be able to tell these apart. The version information pattern helps with this distinction.

- Format information – This pattern contains all the information about error correction and the tolerance of that specific QR code. This is important when thinking about potential damage done to the QR code and how important the information is to be able to recover with a damaged label.

- Data and error correction keys – QR codes have the ability to be read even if the code is 30% damaged. This information is built in with the rest of the data found in a QR code, which is why this threshold exists.

- Quiet zone – Quiet zones in QR codes are just as important as quiet zones in UPC barcodes. This blank space is what helps the scanner distinguish the code and the subsequent ability to read it accurately.

Each of these components is essential to every QR code for scanners to correctly scan the code without any errors.

QR Code Applications

Quick Response codes are becoming more and more ubiquitous as various industries are figuring out ways to implement them into their processes. Some of these applications include:

- Redirecting consumers to locations that display multimedia material such as videos, images, documents, or audio

- The codes can be linked to bank accounts as a secure way to pay for items

- Virtual stores allow the customer to scan a code and have an item shipped to their home

- Website logins

- Joining a wi-fi network

- Can be placed on tombstones to display obituaries and other information about the deceased

- Ordering food at restaurants via a QR code redirection to a menu

- Can be used for reward/loyalty programs at stores

- Counterfeit detection

- Inventory management

- Going paperless for required inspection, incident, and certification documents

The first and foremost application that has stayed consistent since the beginning has been the QR code’s use in inventory management practices. By using QR codes within warehouse settings, employees have the chance to use specialized inventory software that allows them to abandon the error ridden practices that come along with manual inventory management. With a simple scan of a QR code, the user has instantaneous access to information that changes constantly such as the number of items available, the location that the item was scanned, and even notify the user when new product must be purchased due to supplies running low.

Sounds familiar, right? That’s because Kaizen is an excellent partner to QR codes. Having all this relevant information at employees’ fingertips allows them to complete their tasks seamlessly and efficiently. Not only that, but the use of both Kaizen and QR codes allows for full transparency in internal business processes to make sure that everything is running as it should. This has the potential to decrease the number of bottlenecks, long downtimes, or time-wasting mistakes on data entry as so often happens in manually operated inventory management.

Aside from inventory management, QR codes allow companies to go paperless. Storing documents such as incident reports, inspections, and personnel certifications are all required by OSHA. This information compiling quest can become cumbersome when trying to find paperwork and can be an incredible time-sink to the point where employees and managers put the task off to a later date. However, pushing documentations tasks off puts the company at risk of an OSHA citation and puts their employees at risk in terms of not staying up to date on things such as forklift certification or even neglecting to report workplace incidents.

Implementing QR codes into this aspect of workplace safety will save employees hours of labor filling out paperwork and have the information readily available to anyone who has access to this barcode database. Going paperless is also in line with an organized 5S workspace. It keeps the area less cluttered and therefore keeps the space safer.

COVID-19 and QR Codes

Amidst the COVID-19 pandemic, QR codes have begun popping up everywhere to facilitate a touchless environment for customers. With QR code scanners readily built into a variety of brands of smartphones, customers are equipped to not only protect themselves from contracting the virus, but it also protects employees at retail and food establishments, as well as provides an extra layer of efficiency.

Restaurants that promote the use of QR codes don’t have to worry about waste regarding single-use menus or the time it takes to sanitize reusable ones. In another instance, retail establishments have the ability to request customers to scan a QR code to facilitate contract tracing rather than keeping track by writing down their name and contact information, which requires sanitization. Touchless payments are also becoming more popular as the pandemic progresses.

Overall, QR codes have provided access to a safer environments for both employees and customers as people go about their semi-normal days with COVID-19 present. Something also has to be said about the efficiency that has arisen from the gradual increase in popularity of QR codes in 2020 and into 2021, since the transfer of information has become faster and more reliable.

QR Codes vs. Barcodes

This article has briefly mentioned some of the differences between both standard barcodes and QR codes, but here is a compiled list of attributes that show how beneficial QR codes are to the user:

- QR codes can hold up to 7,089 numeric characters, 4,296 alphanumeric characters, 2,953 binary/bytes, or 1,817 kanji/kana characters.

Barcodes hold less than 100 characters normally. There are a variety of barcodes available, but none reach the capacity of a QR code. - QR codes, like many 2D barcodes, have a data correction ability of up to 30%. The specific method that is used to end up with this result is called the Reed-Solomon error correction algorithm.

Barcodes, the 1D variety, do not have any sort of correction ability. This results in an error when scanning a damaged code. - QR codes can be much smaller even though they carry a large amount of information.

Barcodes take up much more space even though they do not hold as much information. - QR codes are able to be edited if information changes. This is common in production facilities where inventory management software and tracking products is necessary for maximum efficiency.

Barcodes only carry static information such as serial numbers and prices. They cannot tell the scanner where an item was last located or procure marketing strategies that change by the week. - QR codes have the ability to be encrypted which makes them much safer to use if sensitive information is involved.

Barcodes cannot be encrypted because they simply cannot hold enough information like a 2D barcode can. - QR codes have the ability to be scanned in any direction.

Barcodes can be finicky when it comes to scanning directional wise.

Overall, there are a lot of great attributes to QR codes that don’t apply to simple 1D barcodes. This allows more versatility when setting up a scanning system within a warehouse as well as provides more flexibility in other aspects of business that could not be previously accessed.

Creating and Generating Codes

Creating and generating QR codes is easy with the help of specifically made QR code generators. There are a number of free applications that exist for this type of barcode creation, Creative Safety Supply even has one that you can find here.

Simple barcode generators like the one linked above have tabs to enter in the desired information. This can be anything from URLs, email addresses, SMS, phone numbers, and even Wi-Fi information. Next, the user has the option for any of the four error correction levels. Once all the information has been inputted, they can then generate the QR code and download it in a PNG or SVG file.

Creating a label is the last step involved in this process. This can be done by either ordering them pre-made from a label manufacturer or printing them in-house with an industrial label printer. There are a variety of pros and cons to both of these options. However, the most important factors to take into account when looking to install these labels is how many are needed and how fast the company wants to have them on hand. If there is a large volume of labels that need to be had in a short amount of time, it might be better to go ahead and invest in an in-house printer as these offer the user instant access to affordable labels. On the other hand, if there aren’t a lot of labels needed, and the project isn’t high priority, then maybe pre-printed labels would be best. It’s all up to the user to determine what will be the best for their current set-up.

Similar Articles

- Pipe Color Codes – ANSI/ASME A13.1

- Your Guide to Pipe Labeling Standards

- Barcode Labeling

- ANSI Color Codes for Pipe Marking

- Rack Labeling

- Introduction to Shipping Container Labeling

- A Simple Guide to Transportation Industry Labeling Strategies

- A Guide to Pipe Marking Standards

- A Quick Guide to Underground Utility Labeling