If you are thinking about implementing Lean manufacturing in your facility, you will want to take some time to understand how it will help the company. Most people understand that Lean manufacturing is a waste reduction and elimination program, but what does that mean on a practical level. Read on to get some good examples of how this type of program can help your company.

Reduced Risk from Inventory

Many companies make the wasteful mistake of over-producing the products that they make. The thinking is often that if they make their product in larger batches, it will cost less per product, therefore saving money. The reality, however, is that when you over-produce, you need to store the extra product, which costs money. In addition, if demand for that product drops, you could be left holding a lot of inventory. This is why Lean manufacturing instructs companies to only product products in as close to exactly the amounts that customers demand.

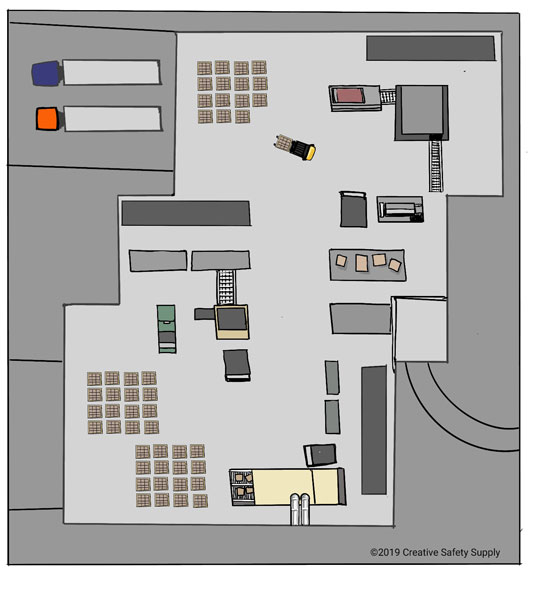

Smart Layout of the Facility

As facilities grow and change, the machines and other equipment used are often just installed wherever they happen to have room at the time when they arrive. Over time, this can lead to huge amounts of wasted motion when employees have to bring work-in-progress products all over the facility to get it completed. Organizing a facility so that production flows efficiently will save a lot of time and energy. Many companies do this by implementing a one-piece flow system. In this system, the facility is laid out in the order of operations. Typically raw materials enter at one side of the building and are immediately moved to the first step of production, located right next to shipping. The production process then flows throughout facility until a finished product is shipped out.

Scheduling for Efficiency

There are many times when a facility has to schedule workers across three shifts, and even all 7 days of the week. If demand drops, however, the facility may simply reduce the number of products each shift needs to produce. This leaves employees and machines just standing around, or else working slower than they should. A better solution would be to cut out certain hours so you’re not paying employees or running machines when it is not necessary. Lean manufacturing offers tools and strategies to reduce changeover times and ensure operators are scheduled efficiently

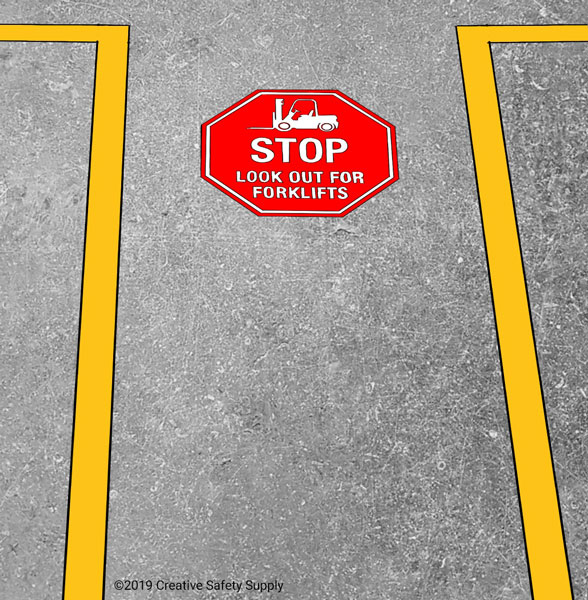

Making Things Safer

Accidents in the workplace are very costly. In addition to the obvious issues of people getting hurt, injuries often result in production stoppages, lawsuits, loss of employees, and many other types of waste. Spending time improving workplace safety should be a big part of Lean manufacturing, and will be a big benefit for everyone.

These, of course, are just a few examples of how Lean manufacturing can benefit a company. In the end, this type of system will save a significant amount of time, energy, and money.

Similar Questions

- What are the 7 (or 8) wastes of Lean manufacturing?

- What are principles of Lean manufacturing?

- What is Lean manufacturing?

- How can Lean affect the supply chain?

- What is 3M in manufacturing?

- Which automobile company initialized Lean manufacturing?

- What do the letters in the acronym DOWNTIME refer to in Lean Methodology?

- Where do I start with Lean manufacturing?

- How does Lean Manufacturing improve quality?